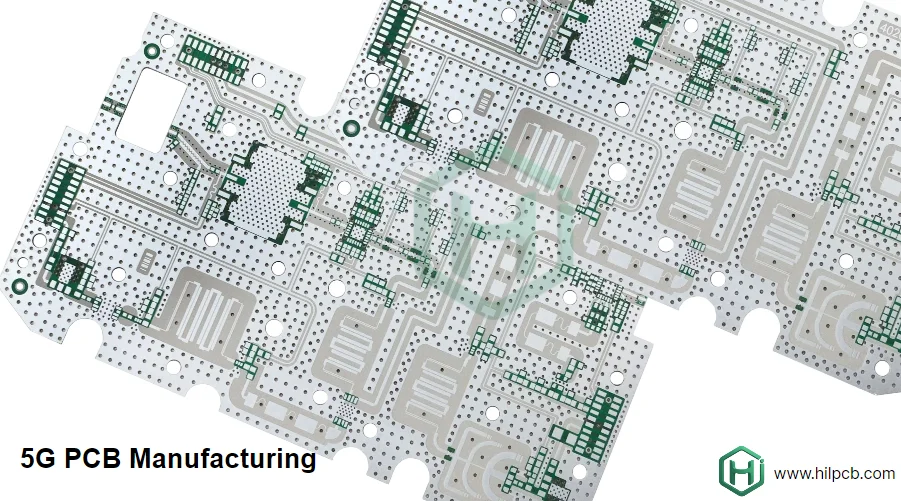

The global deployment of 5G networks represents the most significant advancement in wireless communications in over a decade, delivering speeds 100× faster than 4G, latency below 1 millisecond, and the capacity to connect millions of devices per square kilometer. At the heart of this transformation are 5G PCBs—sophisticated circuit boards operating at millimeter-wave frequencies (24-100 GHz) while managing unprecedented data throughput and power efficiency requirements.

Our specialized 5G PCB manufacturing capabilities enable infrastructure providers and device manufacturers to deliver the performance, reliability, and scalability that next-generation networks demand.

What Sets 5G PCBs Apart from Other PCBs?

5G operates across three spectrum bands, each with unique design challenges. Sub-6 GHz (FR1) requires advanced MIMO antenna arrays, while millimeter-wave frequencies (FR2) demand ultra-low-loss materials and precision manufacturing.

Millimeter-Wave Circuit Challenges: At frequencies above 24 GHz, even small variations in trace width, dielectric thickness, or via geometry can cause impedance mismatches. FR4 materials show excessive loss at these frequencies, making specialized low-loss laminates essential. Our high-frequency PCB process ensures signal integrity across the 5G spectrum.

Massive MIMO Requirements: 5G base stations use massive MIMO with up to 256 antenna elements. This demands PCBs with controlled-impedance traces, minimal crosstalk, and thermal management for high-power amplifiers.

High-Speed Digital Interfaces: 5G equipment integrates high-speed interfaces like 100G Ethernet and DDR4/DDR5 memory. Careful PCB design is crucial to maintain signal integrity through controlled trace lengths, differential pair matching, and efficient power distribution.

Integration Density: With HDI PCB technology, 5G devices achieve high integration, requiring microvias, fine-line traces, and high layer counts to manage complex signals while ensuring thermal and mechanical reliability.

How to Achieve Low Loss and High Speed Signal Transmission

Minimizing insertion loss while maintaining signal integrity across multi-gigabit data rates represents the fundamental challenge in 5G PCB design.

Material Selection for Loss Minimization:

At millimeter-wave frequencies, dielectric loss (tan δ) becomes the dominant contributor to signal attenuation. Standard FR4 materials with tan δ of 0.02 at 1 GHz exhibit even higher losses at 28 GHz, making them unsuitable for 5G RF circuits. We specify ultra-low-loss materials with tan δ below 0.002, including:

- Rogers RO4000 series: Offering balanced performance with tan δ of 0.0027 and compatibility with standard fabrication processes

- Rogers RO3000 series: Providing even lower loss (tan δ 0.0010-0.0013) for the most demanding applications

- Polytetrafluoroethylene (PTFE) composites: Delivering the lowest losses but requiring specialized processing

Material selection balances electrical performance, cost, manufacturability, and thermal management requirements. For hybrid designs combining RF and high-speed digital circuits, we implement multilayer PCB stack-ups using low-loss materials for RF layers and standard materials for digital sections, optimizing both performance and cost.

Controlled Impedance Across Frequency:

Unlike 4G systems operating below 6 GHz, where impedance control targets ±10% tolerance, 5G millimeter-wave circuits require impedance tolerance within ±5% to prevent reflections that degrade signal quality. We achieve this precision through:

- Electromagnetic simulation of every RF trace accounting for frequency-dependent material properties

- Laser direct imaging (LDI) for pattern transfer with resolution to 10 μm

- In-process impedance measurement using time-domain reflectometry (TDR)

- Statistical process control maintaining dimensional tolerances to ±1 mil

Via Design and Transitions:

Signal transitions between board layers using vias introduce parasitic inductance and capacitance that can create impedance discontinuities. At millimeter-wave frequencies, even a standard plated through-hole via appears electrically long, potentially causing resonances that distort signal transmission.

We employ multiple via optimization techniques:

- Blind and buried vias: Minimizing via length reduces parasitic effects while enabling dense routing

- Via back-drilling: Removing unused via stubs eliminates resonances that degrade high-frequency performance

- Ground via fencing: Surrounding RF traces with grounded vias creates a shield preventing coupling to adjacent circuits

- Coaxial via structures: For critical transitions, concentric ground vias around signal vias provide controlled impedance and excellent isolation

Surface Roughness Impact:

At millimeter-wave frequencies, copper surface roughness introduces additional loss through the "skin effect roughness penalty." Standard electro-deposited copper with RMS roughness of 3-5 μm can add 0.3-0.5 dB/inch loss at 28 GHz. We specify reverse-treated foils or very low profile (VLP) copper with RMS roughness below 1 μm, significantly reducing this loss contribution while maintaining adequate copper-to-laminate adhesion.

Differential Signaling:

High-speed digital interfaces in 5G equipment rely on differential signaling to achieve multi-gigabit data rates with acceptable error rates. Differential pair design requires tight control of trace spacing, length matching (typically ±5 mils), and differential impedance (usually 85-100 ohms). Our high-speed PCB design rules and fabrication processes ensure these critical parameters remain within specification across temperature and manufacturing variation.

Ensuring EMI/EMC Compliance for 5G PCBs

We ensure that 5G PCBs meet stringent EMI/EMC standards, providing reliable performance in crowded electromagnetic environments:

- Shielding Strategies: Ground planes, compartmentalized layouts, and grounded via fences to reduce RF interference

- Power Distribution Network (PDN): Robust PDNs with decoupling capacitors and power plane segmentation to prevent noise coupling into RF circuits

- Common-Mode Filtering: Use of common-mode chokes, ferrite beads, and optimized routing to minimize common-mode currents

- Connector and Cable Interface: Filtered connectors and ground stitching to prevent EMI at PCB-to-external transitions, with precision RF connectors for controlled impedance

By implementing these strategies, we ensure your 5G PCBs meet EMI/EMC compliance, maintaining performance while minimizing interference.

How We Ensure High Quality 5G PCB Manufacturing

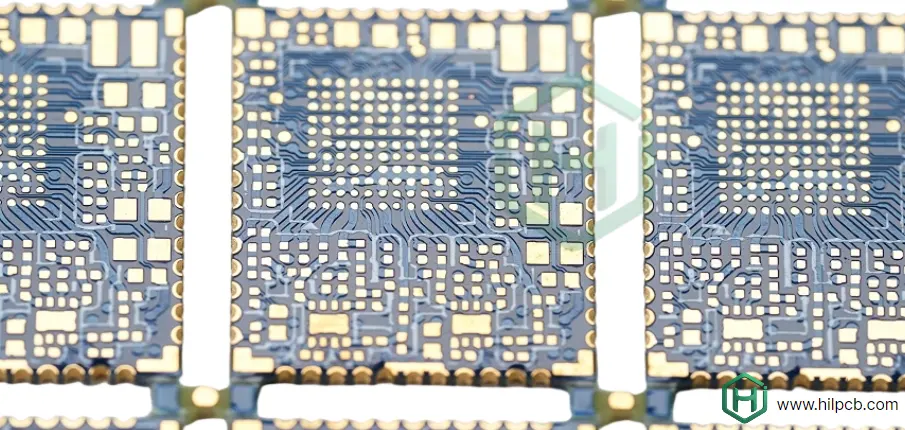

5G PCB manufacturing demands precision and consistency far exceeding consumer electronics, requiring advanced equipment, tight process controls, and comprehensive testing.

Advanced Fabrication Technology:

Our 5G-capable manufacturing facility employs state-of-the-art equipment specifically selected for high-frequency applications:

- Laser Direct Imaging (LDI): Achieving trace width tolerances of ±0.5 mil without the resolution limitations of traditional photographic imaging

- Sequential Lamination: Building complex multilayer boards in multiple press cycles, enabling buried vias and impedance-controlled internal traces

- Laser Drilling: Creating microvias with 75-100 μm diameter and precise depth control for HDI constructions

- Automated Optical Inspection (AOI): 100% inspection of every layer before lamination, catching defects before they're buried in the board

Material Handling and Storage:

Low-loss RF materials require careful handling to prevent moisture absorption that would shift electrical properties. We maintain climate-controlled storage at 45-55% relative humidity and 20-25°C for all laminate materials. Material lots include certificates documenting dielectric constant, dissipation factor, and thickness measured at relevant frequencies—enabling correlation of electrical performance with material properties.

Process Capability and Control:

Statistical process control (SPC) monitors critical parameters including copper thickness (±5% tolerance), dielectric thickness (±10%), registration (±2 mil), and via hole size (±1 mil). When parameters approach control limits, automated alerts trigger process adjustment preventing out-of-specification production. We maintain process capability indices (Cpk) above 1.67 for critical dimensions, ensuring virtual elimination of defects even with normal process variation.

Electrical Testing:

Every 5G PCB undergoes comprehensive electrical testing including:

- Impedance Testing: TDR measurement of every controlled impedance trace verifying 50-ohm single-ended or 100-ohm differential impedance within specification

- Continuity/Isolation: Verification that all intended connections exist and no unintended shorts between traces

- High-Potential Testing: Dielectric strength validation ensuring insulation can withstand operating voltages without breakdown

For RF-critical boards, we perform S-parameter measurements on test coupons representing actual circuit traces, validating insertion loss, return loss, and crosstalk meet design targets across the frequency range of interest.

Environmental Qualification:

5G infrastructure must operate reliably across temperature extremes from -40°C in outdoor deployments to +85°C for equipment room installations. We conduct thermal cycling qualification (typically 500 cycles, -40°C to +85°C) on sample boards from each production lot, followed by microsectioning and reliability testing to verify solder joint integrity and via reliability.

Best Materials for 5G PCBs

Material selection fundamentally determines 5G PCB performance, balancing electrical properties, thermal management, mechanical reliability, and cost.

Rogers RO4000 Series:

RO4000 laminates represent the most widely used material for 5G applications, offering:

- Dielectric constant (Dk) of 3.38-3.48 with tight tolerance (±0.05)

- Low dissipation factor (tan δ = 0.0027 at 10 GHz)

- Thermal conductivity of 0.62 W/mK for heat dissipation

- Compatibility with standard FR4 processing equipment

- Cost-effective compared to PTFE-based alternatives

For 5G massive MIMO base stations, RO4000 materials provide adequate electrical performance at frequencies up to 6 GHz (FR1 band) while offering the mechanical properties and thermal management required for power amplifier arrays. Our Rogers PCB manufacturing expertise ensures optimal stack-up design and process parameters for these materials.

Rogers RO3000 Series:

When loss budgets demand even lower dissipation, RO3000 series laminates deliver:

- Ultra-low tan δ of 0.0010 (RO3003) to 0.0013 (RO3010)

- Stable Dk from -50°C to +150°C enabling consistent performance across temperature

- Excellent mechanical properties for durability in harsh environments

RO3000 materials suit millimeter-wave applications including 28 GHz and 39 GHz 5G bands where every 0.1 dB of loss reduction extends range or enables lower transmit power. The material cost premium over RO4000 justifies itself in applications where RF performance drives system value.

PTFE-Based Composites:

For the most demanding millimeter-wave applications, PTFE-based materials offer:

- Lowest available dissipation factors (tan δ < 0.0009)

- Dielectric constants from 2.1 to 3.5 enabling design flexibility

- Stable electrical properties to 260°C supporting high-temperature operations

PTFE materials require specialized processing including careful handling to prevent delamination and modified drilling/plating procedures. We maintain dedicated processing lines for PTFE boards, ensuring process expertise translates to reliable manufacturing.

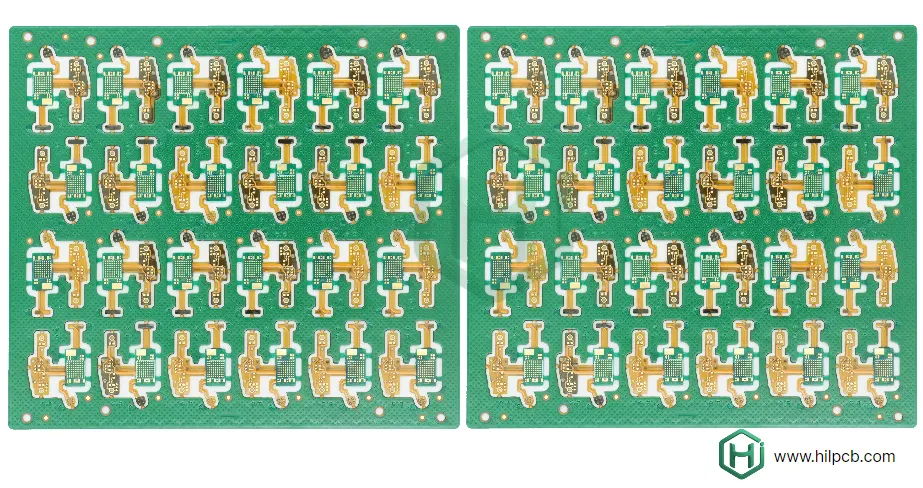

Hybrid Material Constructions:

Many 5G designs optimize cost and performance through hybrid stack-ups combining different materials in a single board. RF signal layers use low-loss materials while digital circuits, power distribution, and mechanical layers employ standard FR4. This approach provides required performance where needed while controlling cost.

We design hybrid stack-ups considering thermal expansion matching between materials, ensuring reliable via barrels and layer-to-layer bonding across temperature cycling. Careful material selection at layer interfaces prevents delamination while maintaining electrical performance.

Optimizing Delivery Times and Costs for 5G PCBs

We streamline the PCB manufacturing process to meet the fast-paced demands of the 5G market, ensuring quick turnarounds and cost-effective production:

- Rapid Prototyping: Functional 5G prototypes in 5-10 working days, with expedited service in 3-5 days for urgent projects

- Design for Manufacturability (DFM): Early consultation to optimize stack-up, impedance, and via structures, reducing prototype iterations by 30-50%

- Scalable Production: Flexible manufacturing for small batch assembly and large volume assembly with consistent quality from prototype to mass production

- Cost Optimization: Maximizing panel utilization, optimizing material selection, and controlling via structures to balance cost and performance

- Global Delivery and Support: Efficient logistics hubs for rapid delivery, with export documentation, compliance certifications, and engineering support for international programs

Our process ensures quick, reliable, and cost-effective solutions for your 5G PCB needs, accelerating time-to-market without compromising quality.

Complete 5G Solutions from Design to Deployment

Success in 5G markets requires more than high-quality PCBs—it demands a manufacturing partner with comprehensive capabilities spanning design, fabrication, assembly, and test.

Our end-to-end 5G capabilities include:

- Advanced PCB fabrication for FR1 (sub-6 GHz) and FR2 (millimeter-wave) applications

- Precision SMT assembly supporting fine-pitch RF components and BGAs with 0.4mm pitch

- RF testing and characterization to 110 GHz validating insertion loss, return loss, and isolation

- Thermal simulation and management for densely packed power amplifier arrays

- EMI/EMC pre-compliance testing reducing risk of regulatory failures

- Complete turnkey assembly from bare boards through programmed, tested modules

Our 5G expertise, combined with vertically integrated manufacturing capabilities, enables faster development cycles, improved product quality, and reduced supply chain risk—accelerating your path to market leadership in next-generation wireless infrastructure.