Highleap PCB Factory (HILPCB) specializes in manufacturing high-quality alumina PCBs that combine excellent thermal performance with cost-effectiveness. Our aluminum oxide substrate processing capabilities deliver reliable ceramic circuit boards for LED lighting, power modules, automotive electronics, and industrial applications where enhanced thermal management and electrical isolation are essential.

Material Properties and Performance Characteristics of Alumina Substrates

Alumina (aluminum oxide, Al2O3) represents the most widely used ceramic PCB material, offering an optimal balance of thermal conductivity, electrical insulation, and mechanical strength at competitive cost points. Our alumina PCB manufacturing utilizes various purity grades to match specific application requirements:

96% Alumina (Standard Grade)

- Thermal conductivity: 24-28 W/m·K

- Dielectric constant: 9.8 at 1 MHz

- Flexural strength: 380 MPa

- Volume resistivity: >10¹⁴ Ω·cm

- Cost-effective for general applications

99.5% Alumina (High Purity)

- Thermal conductivity: 30-35 W/m·K

- Superior surface finish: Ra <0.2μm

- Lower dielectric loss: tan δ <0.0002

- Enhanced mechanical properties

- Ideal for RF and precision applications

99.9% Alumina (Ultra-Pure)

- Maximum thermal performance: 35-38 W/m·K

- Exceptional electrical properties

- Minimal porosity <0.1%

- Premium applications requiring ultimate performance

The thermal expansion coefficient of alumina (6.5-7.5 ppm/K) provides good compatibility with semiconductor devices, while zero moisture absorption ensures dimensional stability in humid environments. These properties make alumina substrates superior to traditional FR-4 PCB materials for applications demanding enhanced thermal management.

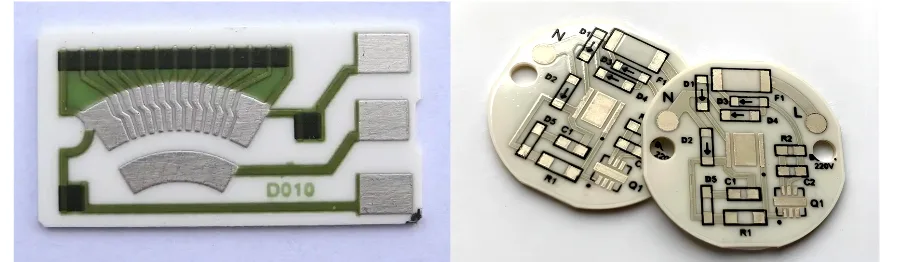

Advanced Metallization Processes for Alumina Circuit Boards

Creating reliable conductive patterns on alumina substrates requires specialized metallization technologies:

Thick Film Technology Our screen printing process deposits conductive pastes with precise control:

- Conductor materials: Ag, AgPd, Au, Cu

- Line width/spacing: 100μm/100μm standard (75μm achievable)

- Multi-layer capability with buried vias

- Resistor and capacitor integration options

- Firing temperature: 850-950°C for optimal adhesion

Thin Film Processing For high-frequency and precision applications:

- Sputtered Ti/Cu/Ni/Au metallization

- Feature sizes down to 25μm lines/spaces

- Superior adhesion through titanium barrier layers

- Compatible with wire bonding and flip-chip assembly

- Controlled impedance for high-frequency PCB applications

Direct Bonded Copper (DBC) High-current applications benefit from our DBC process:

- Copper thickness: 0.127mm to 0.4mm

- Current capacity exceeding 100A

- Excellent thermal cycling reliability

- Ideal for power module substrates

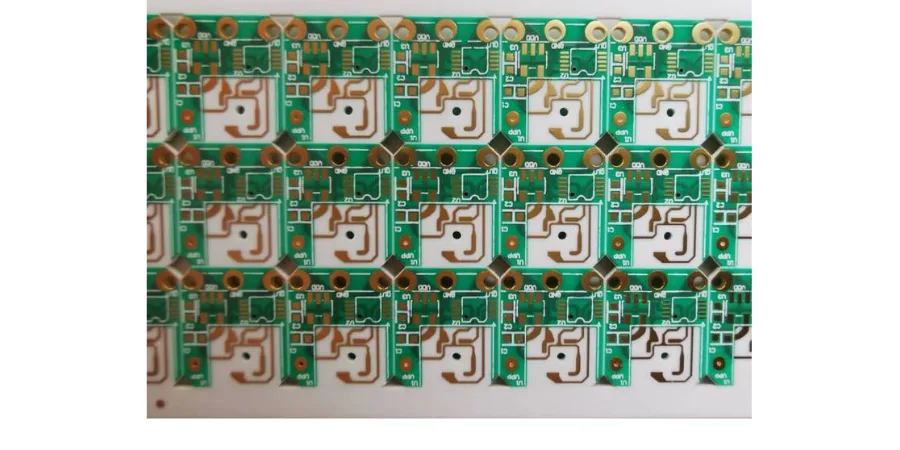

Manufacturing Excellence and Quality Control

HILPCB's alumina PCB production facility incorporates state-of-the-art equipment and rigorous quality systems:

Processing Capabilities

- Thickness range: 0.25mm to 3.0mm

- Camber tolerance: <0.05% of diagonal

- Surface finish options: As-fired, lapped, polished

- Laser drilling: 50μm minimum via diameter

Quality Assurance Measures Every alumina circuit board undergoes comprehensive inspection:

- Automated optical inspection for pattern integrity

- Cross-sectional analysis verifying layer thickness

- Adhesion testing exceeding MIL-STD-883 requirements

- Thermal resistance measurement for power applications

- 100% electrical testing including continuity and isolation

Our ISO 9001:2015 certified quality management system ensures consistent performance across production batches, with full traceability from raw materials through finished products.

Applications and Assembly Services for Alumina PCBs

Alumina ceramic PCBs are widely recognized for their exceptional thermal conductivity, electrical insulation, and long-term reliability. These properties make them indispensable in demanding sectors ranging from medical electronics to power systems and RF communications.

Versatile Applications Across High-Reliability Fields

Medical Devices Alumina substrates are ideal for implantable components and surgical electronics, offering biocompatible metallization and resistance to sterilization processes. They're widely used in medical imaging, patient monitoring, and defibrillator systems requiring high voltage isolation and durability.

LED and Lighting Systems From COB modules delivering over 150 lm/W to UV-C arrays for sterilization and automotive LED headlights, alumina PCBs ensure thermal stability and long lifespan. Applications include horticultural grow lights and high-power stadium lighting rated for 100,000+ operating hours.

Power Electronics and Energy Alumina boards support high-efficiency SiC and GaN power devices, electric vehicle inverters, wind power converters, and industrial drives. They are built to withstand voltage ranges from 600 V to over 1,000 V and operate reliably over 25+ years in renewable energy systems.

RF, Telecom, and Radar Thanks to excellent signal integrity and packaging options, alumina PCBs are used in 5G power amplifiers, satellite links, automotive radar (77 GHz), and military-grade radar modules. They are ideal for compact IoT sensor nodes and hermetically sealed communication devices.

Industrial and Harsh Environments Alumina’s thermal stability enables use in high-temperature sensors (up to 500 °C), oil exploration electronics, aerospace avionics (DO-160 compliant), and factory automation systems where shock, vibration, and temperature extremes are present.

Specialized Assembly Services for Ceramic Substrates

HILPCB offers end-to-end assembly solutions engineered for alumina PCBs:

- Surface Mount Assembly (SMT) with ceramic-optimized thermal profiles and nitrogen reflow.

- Die attachment using gold-tin solder, sintered silver, or conductive epoxy, depending on application needs.

- Wire bonding with gold or aluminum wires ranging from 25–500 μm in diameter, supporting both fine-pitch and high-current devices.

- Flip-chip mounting with underfill for CTE matching, reducing thermal stress.

- Hermetic sealing for applications in medical implants and military-grade systems.

To enhance reliability, we provide conformal coatings, glob-top encapsulation, custom heat sink integration, and EMI shielding. Our turnkey services include electrical testing, X-ray void detection, and full AOI inspection—ensuring each assembled product meets the highest standards for mission-critical performance.

Why Choose HILPCB for Alumina PCB Manufacturing

Selecting HILPCB as your alumina PCB partner provides significant advantages throughout your product development and production lifecycle. Our engineering team brings decades of ceramic substrate experience, offering design optimization suggestions that improve manufacturability while reducing costs. From prototype quantities delivered in 7-10 days to large-volume assembly with monthly capacity exceeding 100,000 units, we scale seamlessly with your requirements.

Our global logistics network ensures reliable delivery worldwide, with specialized packaging protecting fragile ceramic substrates during transit. Multiple payment options including PayPal, wire transfer, and NET terms for qualified accounts simplify procurement. Technical support extends beyond delivery, with our applications engineers available to assist with assembly process development and troubleshooting.

Partner with HILPCB for your alumina PCB needs and experience the difference of working with ceramic substrate specialists who understand the nuances of aluminum oxide materials. Whether you're designing LED modules requiring precise thermal management, power electronics demanding high current capacity, or RF circuits needing stable dielectric properties, our alumina PCB solutions deliver the performance and reliability your applications demand.

Frequently Asked Questions

What advantages do alumina PCBs offer over metal core PCBs?

Alumina PCBs provide complete electrical isolation without requiring dielectric layers that limit thermal performance in metal core designs. The ceramic substrate offers 24-35 W/m·K thermal conductivity while maintaining >10¹⁴ Ω·cm resistivity. Additionally, alumina's thermal expansion better matches semiconductor devices, reducing thermal stress during cycling.

How do 96% and 99% alumina compare for different applications?

96% alumina offers the best cost-performance ratio for general LED and power applications, with 24-28 W/m·K thermal conductivity. 99%+ alumina provides enhanced thermal performance (30-35 W/m·K), lower dielectric loss, and superior surface finish ideal for RF applications and precision circuits requiring tight tolerances.

What are typical lead times for alumina PCB orders?

Standard alumina PCB designs ship in 10-12 days for prototype quantities. Quick-turn service delivers simple designs in 7 days. Complex assemblies with wire bonding or special metallization require 15-20 days. We maintain alumina substrate inventory to minimize material procurement delays.

Can alumina substrates be laser drilled for vias?

Yes, we use CO2 and UV lasers to drill vias in alumina substrates with minimum diameters of 50μm. Laser drilling provides clean, crack-free holes without the mechanical stress of traditional drilling. Via metallization options include filled vias for thermal management and castellated vias for edge connections.

What design guidelines apply to alumina PCB layouts?

Key design rules include: minimum trace width 100μm (thick film) or 25μm (thin film), minimum via diameter 100μm, edge clearance 0.5mm to prevent chipping, and corner radius >0.2mm. We provide detailed design guidelines and offer free DFM review to ensure manufacturability.

How do you handle the brittleness of alumina during assembly?

Our assembly processes incorporate specialized fixtures supporting the substrate during placement and reflow. Controlled heating/cooling rates prevent thermal shock. Pick-and-place equipment uses reduced vacuum and specialized nozzles. These adaptations achieve assembly yields comparable to standard PCBs while protecting ceramic integrity.