Power electronic systems, such as DC-DC converters, motor drives, solar inverters, and switching supplies, face increasing thermal challenges due to higher power density and faster switching speeds. Components like MOSFETs and IGBTs dissipate 5–50W each, concentrating heat that must be kept below 150°C to ensure reliability.

Aluminum base PCB technology addresses these thermal constraints, enabling more compact designs that achieve target power levels without the need for oversized heatsinks or complex cooling systems. This leads to higher efficiency and performance in power applications, ensuring reliable operation even under demanding conditions.

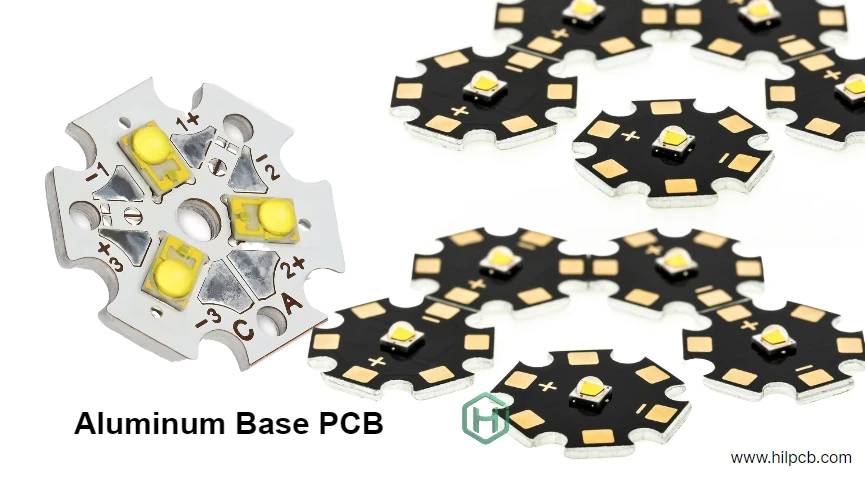

Aluminum Base PCB Types and Their Thermal Advantages

Aluminum Base PCBs—also known as Aluminum Core PCBs, Metal Core PCBs (MCPCBs), or Aluminum Substrate PCBs—are commonly used in high-power applications where effective thermal management is crucial. These PCBs incorporate a thermally conductive aluminum layer as the base substrate, which allows for efficient heat dissipation. This technology is essential for electronic systems that generate substantial heat, such as LED lighting, automotive electronics, and power supplies.

Different Types of Aluminum Base PCBs:

- Single-Layer Aluminum PCB: This type features a single aluminum substrate with a copper circuit layer. It is the most common choice for moderate power applications where cost-effectiveness and efficient heat dissipation are needed.

- Double-Sided Aluminum PCB: This configuration allows traces to be routed on both sides of the aluminum substrate, providing increased circuit density and enhanced thermal dissipation, especially in compact designs.

- Hybrid Aluminum PCB: Combining aluminum with other materials, this type is used for specialized applications where both thermal and electrical performance are paramount.

- Heavy Copper Aluminum PCB: This variation uses thicker copper layers (3 oz to 10 oz) for high-power applications requiring the conduction of large currents and enhanced heat spreading capabilities.

Thermal Management Advantages:

Aluminum Base PCBs outperform traditional FR4 boards by offering significantly higher thermal conductivity, often in the range of 150–200 W/mK, compared to FR4’s 0.3 W/mK. This allows for efficient heat dissipation from high-power components, maintaining lower junction temperatures and preventing overheating.

The use of Aluminum Base PCBs reduces the reliance on external cooling mechanisms like oversized heatsinks or forced-air cooling systems, leading to more compact and cost-effective designs. With Aluminum Substrate PCBs, systems can achieve higher power density without compromising reliability or performance, making them the go-to solution for industries requiring high-efficiency electronics.

Selecting Aluminum Base Specifications for Power Applications

Substrate Thickness Optimization

1.5mm Standard – Balances cost, thermal spreading, and mechanical stability. Adequate for distributed power components up to 3W/cm² density. Standard choice for commercial power supplies and motor controllers under 500W.

2.0mm Enhanced – Improved lateral heat spreading benefits concentrated heat sources (multiple MOSFETs in small area). Better mechanical rigidity for large boards or mounting stress. Required for automotive and industrial applications with vibration requirements.

3.0mm Maximum – Lowest thermal resistance for extreme power densities (>5W/cm²). Cost premium of 30–40% justified only when thermal analysis proves necessity or board area cannot expand.

Dielectric Thermal Conductivity Selection

Standard 1.5–2.0 W/mK dielectrics suit moderate power applications (<50W total dissipation). High-performance 3.0–5.0 W/mK materials reduce thermal resistance 40–60% but cost 50–100% more—justified for power densities 3–6W/cm² or when size constraints limit aluminum area.

For a 10W MOSFET with target 25°C temperature rise:

- Standard dielectric: Requires 16–20 thermal vias (0.4mm diameter)

- High-performance dielectric: Adequate with 10–12 thermal vias

- Premium dielectric: 8–10 vias sufficient

Material selection trades initial cost against via count, board area, and assembly complexity.

Copper Weight Requirements

2 oz Copper (Standard) – Adequate for signal traces and power distribution <10A. Provides good thermal spreading from component footprints.

4–6 oz Copper (Heavy) – Required for 10–30A current paths. Reduces I²R losses improving efficiency 0.5–1.5%. Improves lateral heat distribution before vertical conduction through dielectric.

8–10 oz Copper (Extreme) – Necessary for currents exceeding 50A. Integration with heavy copper PCB technology provides combined electrical capacity and thermal spreading. Cost increase 40–80% justified for high-power applications.

EMI Considerations with Aluminum Base PCB

Ground Plane Benefits

The aluminum base provides inherent electromagnetic shielding:

Low-Impedance Reference: Metal substrate creates near-ideal ground plane minimizing inductance. Reduces common-mode EMI radiation and improves immunity to external interference.

Faraday Cage Effect: Proper grounding to chassis creates partial Faraday cage containing high-frequency switching noise within converter enclosure. Benefits system-level EMC compliance.

Heat Sink Grounding: Direct mounting to grounded heatsink provides both thermal and electrical benefits—simultaneous heat dissipation and EMI containment through single interface.

Layout Techniques for EMI Reduction

Minimize Loop Area: Place gate driver close to MOSFET gate terminal. Route gate traces away from noise-sensitive analog circuits. Aluminum ground plane allows smaller loop areas without ground bounce concerns present in FR4.

Snubber Placement: Position RC snubbers directly across MOSFET drain-source terminals minimizing parasitic inductance. Aluminum substrate's thermal conductivity allows snubbers to dissipate switching energy without overheating.

Input Filter Location: Place bulk capacitors and EMI filter components opposite board side from switching nodes when possible. Use aluminum substrate as shield between noisy power stage and quiet control circuits.

HILPCB Power Electronics Manufacturing with Aluminum Base PCB Solutions

At HILPCB, we offer comprehensive PCB manufacturing and assembly services for a wide range of applications, including power electronics such as DC-DC converters, motor drives, solar inverters, and power supplies. Our expertise spans across all types of PCBs, including Aluminum Base PCBs, FR4 PCBs, metal core PCBs, and flexible PCBs, providing robust solutions for even the most demanding thermal management needs.

Our Specialized PCB Services Include:

- Heavy Copper Integration: Selective electroplating builds 4–10 oz copper in high-current areas while maintaining 2 oz copper in signal sections. This ensures efficient thermal dissipation and optimized current capacity for high-power PCB designs.

- Via Filling Services: We offer epoxy filling for via-in-pad power device mounting, ensuring reliable solder joints and optimal heat conduction, especially for thermal pads on Aluminum Base PCBs.

- Thermal Analysis: Our finite element modeling (FEM) simulations predict junction temperatures under worst-case conditions. We validate thermal performance for all PCB types, ensuring reliable operation even in high-power and high-temperature environments.

- High-Voltage Testing: We conduct dielectric breakdown testing to verify isolation between the circuit and substrate, ensuring all PCBs, including Aluminum Base PCBs, meet industry standards for high-voltage applications.

- Automotive Qualification: Our IATF 16949 certified manufacturing processes meet the strict quality standards required for automotive applications, providing full traceability and documentation to support PPAP requirements for Tier 1 automotive suppliers.

Whether you're developing consumer power adapters, industrial motor drives, or automotive power modules, HILPCB delivers high-quality PCB manufacturing and assembly services for all your thermal management and high-power design needs. Our solutions ensure reliable, efficient performance, reducing the need for oversized cooling systems and enhancing overall system reliability.