Aluminum PCB assembly is a vital process for building high-performance electronics where efficient heat dissipation is crucial. This guide explains the essential steps, challenges, and quality methods that ensure stable and reliable production of aluminum-based printed circuit boards.

The Core Steps of Aluminum PCB Assembly

The aluminum PCB assembly process involves multiple stages that determine electrical reliability and thermal performance. These include:

- Solder Paste Printing – The process starts by applying solder paste through a precision stencil, similar to what’s used in advanced SMT assembly.

- Component Placement – Components are placed using high-accuracy pick-and-place machines to ensure proper alignment and consistency.

- Reflow Soldering – The assembly is passed through a reflow oven where the solder bonds components to the aluminum substrate.

- Inspection and Testing – Techniques such as AOI and X-ray inspection validate solder joint integrity before functional testing.

- Cleaning and Packaging – Boards are cleaned and securely packed to maintain surface quality before shipment.

Common Challenges in Aluminum PCB Assembly

While aluminum PCBs are highly effective for thermal management, they introduce specific challenges during the assembly process. Some of these challenges include:

- Thermal Expansion Mismatch Aluminum expands at a different rate than most solder materials. This mismatch can stress joints during reflow soldering. In some designs, combining aluminum with FR4 PCBs helps balance the performance of different layers.

- Soldering Control The aluminum base conducts heat rapidly, which can affect the soldering process. Precise temperature control is essential to prevent cold solder joints. Adjusting the soldering temperature profile for aluminum substrates ensures optimal results.

- Component Alignment Just like in HDI PCBs, aluminum PCB assembly requires precise component placement to avoid electrical faults. Misalignment can lead to poor connections or board failure, especially in high-density designs.

- Thermal Stress Management Managing thermal stress is crucial to ensure the stability of solder joints. The design should incorporate effective heat dissipation pathways to prevent overheating and ensure long-term durability.

Improving Aluminum PCB Assembly Quality and Efficiency

Enhancing the quality and efficiency of aluminum PCB assembly requires careful engineering and process control. Here are some strategies to improve assembly outcomes:

- Optimized PCB Stackup Multi-layer layouts can follow best practices from multilayer PCB design. This ensures that current flows efficiently and heat is effectively managed across the entire board.

- Advanced Materials Combining aluminum substrates with high-thermal PCBs helps handle extreme temperatures without delamination. These materials also ensure that the PCB performs reliably in demanding environments.

- Automated Inspection Systems Implementing advanced inspection systems such as optical and 3D inspection technologies enables higher quality monitoring, reducing human error and ensuring more accurate detection of defects.

- Process Automation Automation plays a critical role in enhancing efficiency. By reducing manual errors and increasing consistency, automation ensures uniformity across large production batches, particularly for precision assemblies.

Applications of Aluminum PCB Assembly

Aluminum PCBs are commonly used in sectors that require strong power and heat management performance:

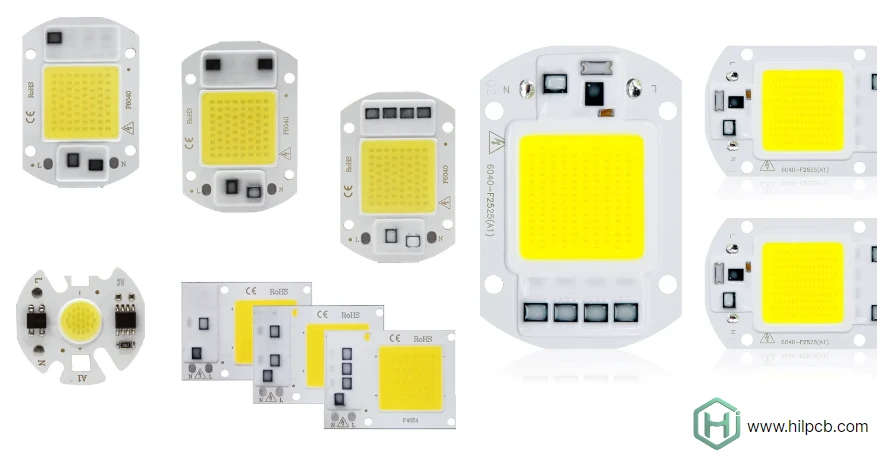

- LED Lighting: Aluminum substrates are the standard for high-intensity lighting systems, offering excellent thermal conductivity.

- Automotive Electronics: Aluminum boards are used in headlights, sensors, and control modules, often combined with rigid-flex PCB designs for reliability in compact spaces.

- Power Supplies: High-current systems use aluminum layers in combination with heavy copper PCBs to carry large power loads safely.

- High-Frequency Devices: For RF and microwave systems, aluminum boards often complement high-frequency PCBs to improve impedance stability and signal clarity.

- Industrial Control Units: Rugged power drivers and converters rely on thermal efficiency to maintain stability in harsh environments.

Quality Control Standards in Aluminum PCB Assembly

Reliable aluminum PCB assemblies require adherence to international standards and advanced testing methods:

- IPC Class 2 & 3 Compliance: Ensures structural and functional integrity under stress conditions.

- AOI & Functional Testing: Detects solder defects and verifies circuit performance before final delivery.

- Thermal Cycling Tests: Simulates extreme temperature variations for durability validation.

- Prototype Verification: Rapid trials using small batch assembly help catch issues early before mass production.

- Material Certification: Each batch passes internal traceability checks for consistency and compliance.

Choosing a Reliable Aluminum PCB Assembly Partner

When choosing an aluminum PCB assembly partner, it’s essential to select a manufacturer with the right expertise and resources. Look for a company that offers:

- Proven Experience in PCB Technologies A trusted partner should have experience across various PCB technologies, from multilayer PCBs to high-power systems, ensuring they can handle complex designs and meet your project requirements.

- Comprehensive Services The ideal manufacturer should offer integrated services that include fabrication, assembly, and testing, with strict quality control at each stage of production.

- Collaboration and Support Engineering collaboration is key to optimizing thermal layouts, material selection, and assembly methods before production begins. Ensure your chosen partner provides the necessary technical expertise to fine-tune your design.

At HILPCB, every project is treated as a partnership. Our team combines advanced production equipment with deep technical expertise to deliver consistent quality and on-time results—whether for prototypes or mass production. We focus on thermal performance, signal integrity, and cost efficiency to help your brand accelerate its path from concept to reliable finished product.