Choosing an aluminum PCB manufacturer is not only about sourcing a single product type — it’s about forming a partnership with a supplier who can support your complete PCB and assembly requirements. At HILPCB, we provide full-spectrum PCB manufacturing services, including FR4, multilayer, HDI, flex-rigid, ceramic, and metal-core PCBs, as well as complete PCBA assembly under one roof.

A dependable manufacturer ensures your designs move smoothly from prototype to production, maintaining quality consistency, scalability, and on-time delivery. This guide explains what defines a reliable aluminum PCB manufacturer and how to evaluate potential partners for long-term cooperation and product success.

How to Identify a Reliable Aluminum PCB Manufacturer

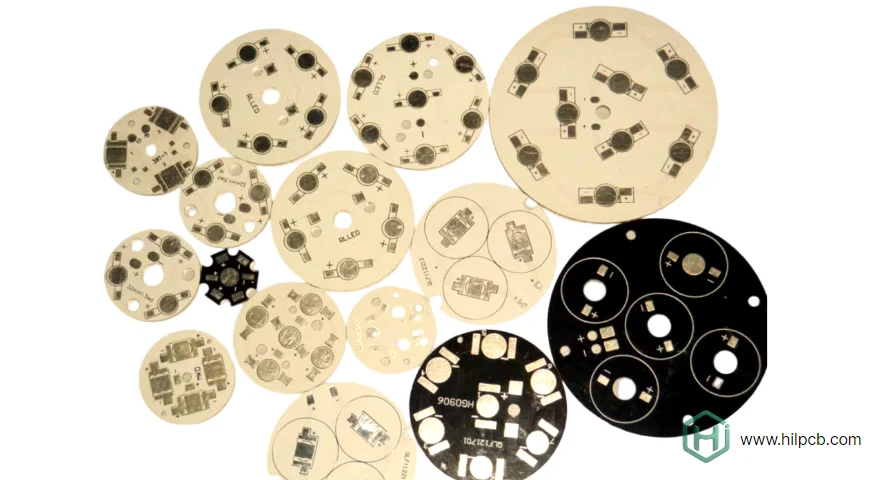

Identifying the right partner starts with evaluating their technical expertise, facility capability, and quality systems. A professional factory should have extensive experience producing single and double-layer PCBs and advanced metal-core configurations while maintaining tight process control. When assessing potential manufacturers, consider:

- Material and Design Experience – Look for proven background in metal-core PCB fabrication for high-power applications.

- Facility Infrastructure – Modern plants equipped with precision etching, laser drilling, and automated inspection systems.

- Engineering Support – Reliable manufacturers provide DFM consultations and thermal design feedback.

- Quality Certifications – Verify ISO 9001, IATF 16949, and UL certifications as proof of compliance.

Production Capabilities and Technical Expertise

Comprehensive production capability defines how consistently a manufacturer can meet specifications.

- Thermal Materials – Expertise with aluminum alloys and dielectrics similar to those used in high-thermal PCBs.

- Copper Control – Tight tolerance management ensures consistent current capacity and thermal performance.

- Advanced Fabrication – Factories experienced in fine-line circuits often apply technology comparable to HDI PCB processes.

- Performance Validation – In-house thermal and electrical testing ensures reliability before shipment.

These capabilities ensure precision and repeatability from prototype to volume manufacturing.

Why Manufacturing Experience Matters

Choosing the right aluminum PCB manufacturer goes far beyond quoting prices — it’s about ensuring reliability, consistency, and technical precision. An experienced factory understands how materials, stack-up design, and thermal behavior affect long-term performance. This knowledge minimizes manufacturing defects, improves electrical stability, and guarantees boards that perform under demanding conditions.

A seasoned China aluminum PCB manufacturer also offers strong engineering collaboration. Before fabrication begins, their DFM and DFA teams review your files to optimize trace design, copper balance, and heat dissipation. This proactive approach helps prevent costly redesigns and accelerates time-to-market — a key advantage when developing high-power LED modules, power converters, or industrial control boards.

Manufacturers with years of experience also excel at hybrid builds such as FR4-aluminum composite PCBs and complex multilayer structures. Their process mastery ensures reliable lamination, superior thermal conductivity, and consistent adhesion strength. When you partner with a proven aluminum PCB supplier like HILPCB Factory, you gain more than production capacity — you gain a trusted engineering partner dedicated to precision, performance, and on-time delivery.

Quality Control and Assurance

World-class manufacturers implement systematic quality management and multiple inspection checkpoints throughout production.

- Material Verification – Substrate and copper foil testing for conductivity and adhesion.

- AOI & Electrical Testing – Automated inspection similar to methods used for high-frequency PCBs.

- Thermal Validation – Confirming heat dissipation performance under actual working conditions.

- Continuous Monitoring – Real-time process data ensures consistency and traceability.

A robust quality framework ensures defect-free boards and long-term reliability.

Integrated Assembly and Manufacturing Services

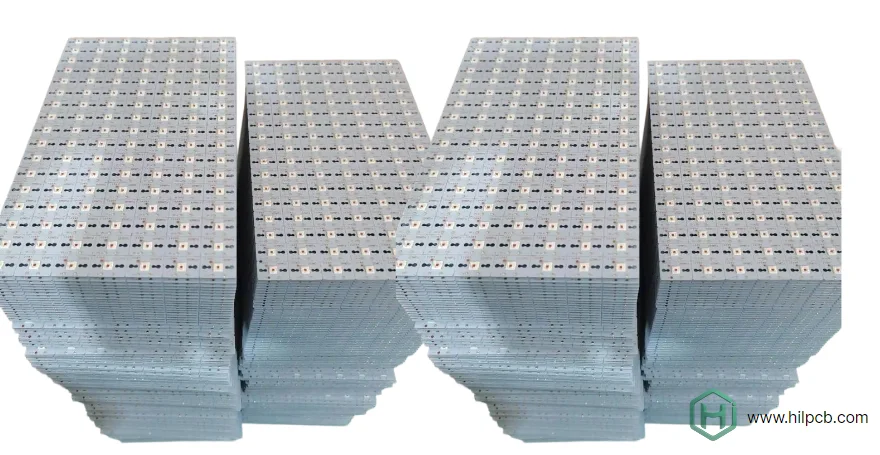

A reliable aluminum PCB manufacturer should offer more than just board fabrication — it should deliver a fully integrated manufacturing ecosystem. At HILPCB, fabrication and assembly are managed under one roof, ensuring seamless communication, faster production cycles, and tighter quality control.

Our comprehensive model covers every stage of production, including:

- SMT assembly for precise and automated component placement on aluminum and mixed-material boards.

- Turnkey assembly that integrates material sourcing, fabrication, assembly, and testing into one streamlined process.

- Box-build assembly for complete product integration — from PCB to finished electronic device.

This one-stop solution eliminates multi-supplier coordination, shortens lead times, and ensures consistent quality from the bare aluminum PCB to the final assembled product. Whether for LED lighting, automotive, or power electronics, partnering with an integrated PCB manufacturing and assembly factory like HILPCB ensures your project runs efficiently from prototype to mass production.

Conclusion

Selecting the right aluminum PCB manufacturer goes beyond technical capability — it’s about working with a partner that offers manufacturing depth, engineering expertise, and reliable support across every stage of your project.

At HILPCB, we combine precision PCB fabrication with complete assembly services, enabling our customers to consolidate suppliers and simplify project management. Our capabilities span FR4, HDI, metal-core, flex-rigid, and ceramic PCBs, all supported by advanced SMT and turnkey assembly lines.

Whether you’re developing LED drivers, automotive control modules, or power conversion systems, our team ensures consistent performance, cost efficiency, and dependable delivery at every production scale. Partner with HILPCB — a trusted China PCB manufacturer committed to quality, flexibility, and long-term cooperation.