China has become the global center for aluminum PCB manufacturing, known for its strong supply chain, competitive pricing, and advanced technical expertise. For international buyers, understanding how to evaluate and select the right China PCB factory is essential to ensure both cost efficiency and long-term reliability.

At HILPCB, we represent the new generation of aluminum PCB manufacturers in China — combining advanced fabrication technology, rigorous quality systems, and comprehensive assembly solutions. Whether for LED lighting, automotive systems, or industrial controls, partnering with a professional China-based factory guarantees consistent quality and faster turnaround.

1. Why China Dominates Aluminum PCB Manufacturing

China’s leadership in metal-core PCB production is built on three core strengths: integrated supply chains, scale-driven cost efficiency, and technological innovation.

- Supply Chain Integration – Access to raw materials like high-purity aluminum, copper foils, and thermal dielectrics enables stable production and shorter lead times.

- Manufacturing Clusters – Cities such as Shenzhen and Dongguan concentrate thousands of specialized suppliers, ensuring rapid prototyping and scalable volume production.

- Technology Investment – Modern facilities deploy laser drilling, AOI, and thermal simulation testing comparable to global Tier 1 standards.

- Cost Advantage – Due to automation and high-volume capability, prices are typically 30–50% lower than Western manufacturers for the same quality.

This combination of scale and precision allows China to deliver both single and double-layer PCBs and complex metal-core PCBs for diverse global markets.

2. Technical Capabilities of China’s Top Manufacturers

Leading factories in China have evolved far beyond simple fabrication—they provide complete thermal, electrical, and mechanical engineering solutions.

- Thermal Management Expertise – Specialized in high-thermal PCBs with conductivity ratings up to 8.0 W/mK.

- Copper Weight Precision – Control of 1–10 oz copper layers ensures stable current and heat performance for power electronics.

- Hybrid Stackups – Integration of FR4 and aluminum for advanced multilayer or HDI PCB layouts.

- Surface Finishes – ENIG, OSP, HASL, and immersion silver processes optimized for SMT assembly and RoHS compliance.

These capabilities enable manufacturers to deliver performance-critical boards for LED, automotive, and communication equipment with unmatched reliability.

3. Quality Systems and Industry Certifications

Quality is the foundation of every reputable China PCB factory. The best manufacturers maintain international certifications and process control systems that ensure traceability and compliance.

- ISO 9001 – Standardized quality management.

- IATF 16949 – Required for automotive applications.

- UL Certification – Compliance with U.S. electrical safety standards.

- RoHS & REACH – Environmental protection and material safety.

In addition, advanced factories perform comprehensive electrical and thermal tests, including insulation resistance, impedance control, and thermal cycling. These validation methods are similar to testing used in high-frequency PCBs.

4. Engineering Collaboration and Design Optimization

What truly sets apart top-tier Chinese manufacturers is their engineering collaboration.

Rather than simply executing designs, they offer proactive technical input to improve manufacturability and cost-efficiency.

Professional DFM reviews assess layout, copper balance, and thermal via placement to minimize risk. DFA and assembly-oriented feedback are also provided for seamless integration into turnkey assembly processes.

Stack-up consultation, dielectric selection, and thermal simulation further enhance design reliability — helping global clients accelerate development cycles and avoid costly redesigns.

5. Integrated Manufacturing and Assembly Solutions

A modern aluminum PCB factory like HILPCB is more than just a board producer — it’s a complete electronics manufacturing partner. By integrating PCB fabrication, assembly, testing, and packaging under one roof, we help customers streamline their supply chains and accelerate product launches.

Our production system covers the full spectrum of capabilities:

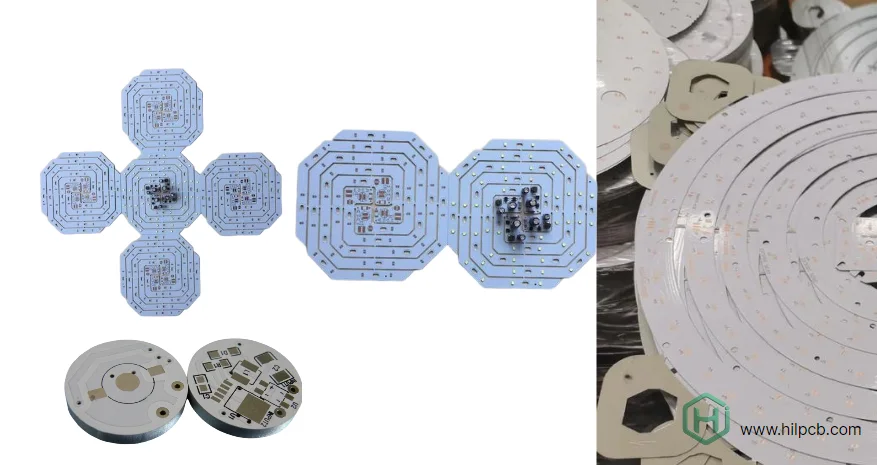

- PCB Manufacturing: From small-batch PCB prototypes to large-volume PCB production, we fabricate all major board types including multilayer, HDI, rigid-flex, FR4, and metal-core PCBs.

- PCB Assembly: Our high-speed SMT assembly and through-hole assembly lines support everything from prototype runs to mass production, ensuring precision, efficiency, and repeatable quality.

- PCB Testing: Each board undergoes 100% electrical testing, AOI inspection, and functional verification to guarantee performance reliability before shipment.

- PCB Packaging and Enclosures: We provide protective PCB packaging, conformal coating, and custom enclosure integration, ensuring mechanical durability and safe delivery of finished assemblies.

- Box-Build and System Integration: Complete product assembly services — from circuit board installation to final product boxing and labeling — ready for market deployment.

This all-in-one model allows HILPCB to deliver consistent results, faster turnaround, and complete traceability — whether you need quick-turn prototypes or high-volume PCB manufacturing and assembly for complex electronic systems.

6. How to Evaluate a China Aluminum PCB Manufacturer

Selecting the right manufacturing partner requires more than comparing quotes. A systematic evaluation should cover:

- Production Capabilities – Check size range, copper weights, and thermal performance.

- Quality Documentation – Request ISO certificates, UL listings, and process audit reports.

- Engineering Communication – Assess responsiveness and technical clarity.

- Prototype Testing – Compare multiple factories with identical specs to evaluate precision and consistency.

- Business Stability – Review operational history and customer references for long-term reliability.

Professional factories are transparent with documentation and often offer virtual tours or sample kits before full-scale production.

Conclusion

China’s aluminum PCB manufacturing industry continues to define the global benchmark for performance, cost efficiency, and scalability. Selecting a capable partner requires evaluating not only technology and certifications but also communication, engineering collaboration, and integrated service scope.

HILPCB stands among the leading aluminum PCB manufacturers in China, delivering end-to-end solutions from precision fabrication to full electronic assembly. Our goal is to empower customers with reliable quality, transparent communication, and a manufacturing partnership built on trust and innovation.