Aluminum-based Printed Circuit Boards (PCBs) are revolutionizing modern electronics, offering significant improvements in thermal management, performance, and durability. In this article, we explore the essentials of aluminum PCB manufacturing, its advantages, key processes, and why it is the preferred choice for a wide range of electronic applications.

What is Aluminum PCB Manufacturing?

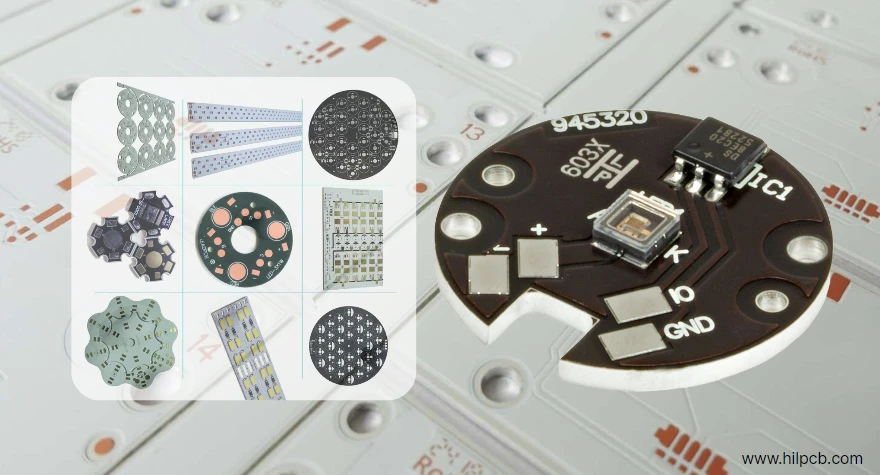

Aluminum PCBs, also known as metal core PCBs, feature an aluminum substrate that serves as a base for the circuit. This unique construction allows for efficient heat dissipation, making them ideal for applications that generate significant heat, such as power supplies, LED lighting, automotive electronics, and high-power LED devices. The aluminum core acts as an excellent conductor of heat, enabling more compact and reliable designs.

The manufacturing process for aluminum PCBs involves several key steps:

- Material Selection: Aluminum substrate with a dielectric layer is selected based on specific thermal and electrical requirements.

- Copper Cladding: Copper is bonded to the dielectric layer to form the circuit.

- Etching: The copper layer is etched to create the desired circuit pattern.

- Lamination: The aluminum core is laminated to the copper and dielectric layers to form the final PCB.

Advantages and Features of Aluminum PCB Manufacturing

Aluminum PCBs offer numerous advantages over traditional FR4-based PCBs:

- Superior Thermal Management: The aluminum core provides excellent heat dissipation, preventing components from overheating and extending their lifespan.

- High Durability: Aluminum’s resistance to corrosion and physical stress enhances the longevity and reliability of the PCB.

- Compact and Lightweight: The use of aluminum allows for more compact designs, ideal for small, high-performance electronic devices.

- Enhanced Performance: The improved heat management translates into better performance, especially in high-power applications such as LEDs and automotive electronics.

These features make aluminum PCBs the ideal choice for high-power applications that require thermal efficiency, reliability, and compactness.

Key Processes and Techniques in Aluminum PCB Manufacturing

The manufacturing of aluminum PCBs requires precision and attention to detail, especially when it comes to the following key processes:

- Copper Cladding and Etching: A thin layer of copper is bonded to the aluminum core, and then a photolithography process is used to create the circuit pattern by etching away the unwanted copper.

- Lamination: After the copper is etched, a dielectric layer is added between the copper and the aluminum core. This lamination process ensures electrical insulation and facilitates effective heat transfer.

- Drilling and Plating: Holes are drilled for component leads, and plated to ensure electrical connectivity between different layers of the PCB.

- Testing and Quality Control: Rigorous testing is done to ensure the thermal conductivity, electrical performance, and structural integrity of the PCB. This may include thermal cycling tests, electrical testing, and visual inspections.

These processes ensure that aluminum PCBs meet high standards of quality and performance, especially in applications with stringent thermal and electrical requirements.

Why Aluminum PCBs Are the Preferred Choice in Modern Electronics

The shift towards aluminum PCBs in modern electronics can be attributed to their distinct advantages:

- Thermal Efficiency: As electronic devices become more powerful, managing heat has become increasingly critical. Aluminum PCBs provide superior heat dissipation, reducing the risk of overheating and component failure.

- Reliability in Harsh Environments: Aluminum’s robust properties make these PCBs ideal for applications in demanding environments, including automotive and industrial sectors.

- Cost-Effectiveness: While initially more expensive than traditional FR4 PCBs, the long-term reliability and performance benefits of aluminum PCBs offer a better overall cost-effectiveness.

In applications such as high-power LED lights, automotive electronics, and medical devices, aluminum PCBs have become the go-to solution for enhancing performance and ensuring longevity.

Quality Control and Challenges in Aluminum PCB Manufacturing

Despite their many benefits, aluminum PCBs come with manufacturing challenges that require careful attention:

- Thermal Expansion Mismatch: The expansion rates of aluminum and other PCB materials must be carefully managed to avoid stress during temperature fluctuations.

- Material Variability: Variations in the quality of aluminum and dielectric materials can affect the overall performance of the PCB. Consistent material sourcing is essential.

- Etching Precision: Achieving precise etching in the copper layer is critical for ensuring the proper functionality of the circuits.

To overcome these challenges, manufacturers like HILPCB employ advanced technologies and stringent quality control processes, ensuring that the final product meets the highest standards of thermal and electrical performance.

How to Choose the Right Aluminum PCB Manufacturer

Selecting the right aluminum PCB manufacturer is a strategic decision that directly impacts product reliability and time-to-market. For professional buyers and engineering teams, the following factors are key to evaluating a qualified supplier:

- Proven Industry Experience: Partner with a manufacturer experienced in metal-core and thermal management PCB fabrication, capable of supporting diverse industrial and power electronics applications.

- Comprehensive Quality Assurance: Confirm that the supplier follows strict process controls, including thermal cycling, impedance verification, and 100% electrical testing to ensure long-term performance stability.

- Engineering and Customization Support: Choose a partner who offers flexible stackup design, material selection, and copper thickness customization to align with your technical and functional requirements.

- Reliable Delivery and Cost Efficiency: Assess their production scalability, lead time consistency, and cost control practices to maintain supply chain stability without compromising quality.

Collaborating with a dependable manufacturer such as HILPCB ensures predictable delivery, consistent quality, and strong technical support throughout every stage of your aluminum PCB project.