Prototype manufacturing bridges the gap between design and full production. For aluminum PCB projects, it ensures thermal, electrical, and mechanical performance are verified under realistic conditions — before mass investment begins.

At HILPCB, we combine rapid aluminum PCB prototyping with production-grade processes, supporting both small-batch and volume-scale transition. Our end-to-end services — from metal-core PCB fabrication to turnkey assembly — provide reliable, production-representative results in just 5–7 days.

1. Why Professional Prototyping Matters

Production-Grade Accuracy

A high-quality prototype uses the same materials, lamination pressure, and dielectric systems as full-scale manufacturing — ensuring results translate directly to production. Even slight variations in thermal interface layers can distort heat-transfer data for high-thermal PCBs.

Fast and Consistent Turnaround

5–7 day delivery is achieved through lean workflows and prototype-dedicated lines — not shortcuts. Automation, real-time scheduling, and fast material access ensure reliability without compromising traceability.

Iteration Support

Each prototype cycle serves a distinct purpose:

- Proof-of-concept validation

- Layout and material optimization

- Pre-production confirmation

Every iteration moves your design closer to mass production readiness.

2. Prototype Fabrication Capabilities

Material Options

Thermal conductivity range:

- 1–2 W/mK: Standard cost-effective builds

- 2–4 W/mK: Balanced LED and control circuits

- 4–6 W/mK: High-power or automotive systems

- 6–8 W/mK: Extreme-performance applications

Base alloys: 5052, 6061, 1100 aluminum.

Copper & Surface Finish

- Copper weight: 1–10 oz (standard to heavy copper)

- Finishes: HASL, ENIG, OSP, or immersion silver — compatible with SMT assembly and lead-free soldering.

Precision & Scale

- Min trace/space: 100–150 µm

- Drill size: 0.3 mm typical

- Hybrid FR4-aluminum builds and HDI PCB structures for high-density designs.

3. Design Validation and Testing

Comprehensive validation ensures prototypes reflect actual performance before production investment.

Thermal Testing

- Junction-to-base resistance measurements

- Infrared imaging under operating load

- Temperature rise mapping

Electrical & Mechanical Testing

- Continuity and isolation checks

- Impedance control validation

- Hi-pot testing up to 3000V

- Mechanical flatness and adhesion inspection

Assembly Verification

- Small-batch builds (5–50 pcs) for process trials

- Reflow simulation with aluminum base thermal profiles

- Post-reflow X-ray inspection and solder analysis

Environmental Testing

- Thermal cycling (-40°C to +125°C)

- Humidity and vibration exposure

- Aging and reliability simulation

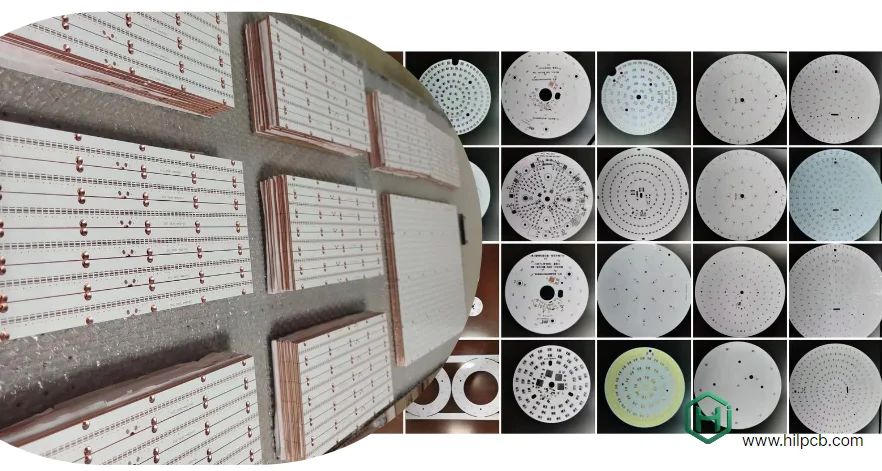

4. Small-Batch and Large-Volume Transition

After prototype validation, many customers require small-batch or pilot runs before full-scale production. HILPCB bridges these stages seamlessly with flexible capacity and consistent quality systems.

Small-Batch Production (50–1000 pcs)

- Ideal for design verification, beta testing, or limited product release

- Same materials, stack-up, and processes as volume runs

- Enables early market feedback while controlling cost

Large-Volume Manufacturing (1000+ pcs)

- Automated panelization for cost optimization

- Statistical process control for repeatability

- Supply chain integration for stable component sourcing

Both stages use unified quality systems, ensuring results scale predictably from prototype to mass manufacturing.

Parallel Scaling Advantage:

During small-batch production, our engineering team refines process parameters and tooling for upcoming high-volume runs — shortening your time-to-market by up to 40%.

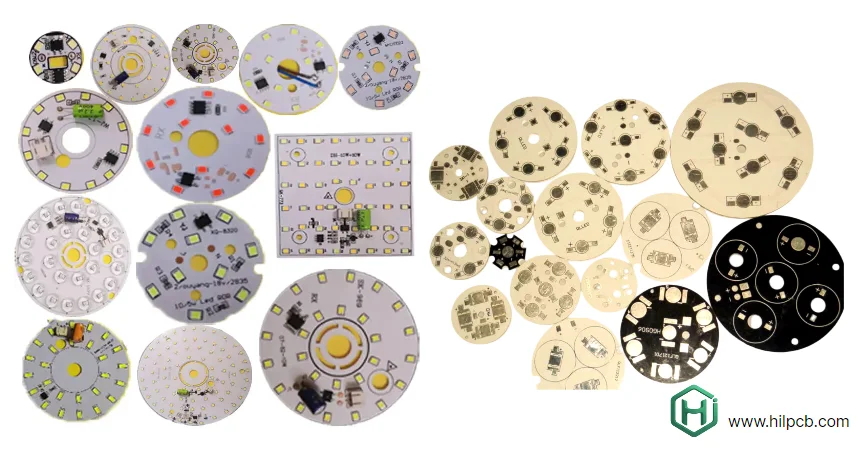

5. Comprehensive PCB Prototyping Capabilities

While aluminum PCBs are core to thermal management applications, we also provide rapid prototyping for other PCB technologies, enabling mixed-technology product development.

- FR4 PCB: Standard rigid boards for control and signal circuits.

- Flex PCB: Lightweight flexible circuits for wearables or compact modules.

- Rigid-Flex PCB: Combines rigidity and flexibility in one structure.

- High-Frequency PCB: RF and microwave boards with controlled impedance.

- Ceramic PCB: Exceptional heat resistance and dielectric stability for precision sensors.

This multi-technology capability allows single-source management — particularly valuable when aluminum substrates are part of hybrid or multilayer assemblies.

6. Selecting the Right Prototype Partner

When choosing a prototype supplier, consider:

- Proven aluminum and hybrid PCB expertise

- Small-batch and volume-scale readiness

- ISO 9001 and IPC-A-600 process certification

- DFM and thermal analysis support

- Transparent communication and pricing

A capable partner ensures not only quick turnaround but also a consistent path to reliable, high-volume manufacturing.

Conclusion

Aluminum PCB prototype manufacturing lays the foundation for fast, reliable product development. By integrating rapid prototyping, small-batch flexibility, and multi-type PCB capability, you can validate your designs faster and scale with confidence.

HILPCB combines short lead times, precision fabrication, and cross-technology expertise — from aluminum and FR4 to flex and ceramic boards. Whether you need a single prototype, a 500-piece pilot run, or full-scale production, we provide seamless, high-quality manufacturing that accelerates your innovation cycle.