At HILPCB Factory, we specialize in PCB manufacturing and PCB assembly, offering complete solutions from prototyping to mass production. Our aluminum PCB prototyping service helps engineers validate their designs, test thermal performance, and speed up time-to-market — all within a controlled, high-precision production environment.

Aluminum PCB prototyping plays a vital role in developing high-power electronics that demand excellent heat dissipation and mechanical reliability. This article explores how rapid aluminum PCB prototyping accelerates your product development, enhances performance, and minimizes design risks before scaling into full production.

Why Aluminum PCB Prototyping is Crucial

Aluminum PCB prototyping involves creating functional circuit boards to test designs, validate thermal management, and ensure manufacturability. This phase helps identify and fix potential issues early, avoiding costly changes during mass production.

Prototyping validates:

- Thermal performance: Ensures high-power components like LEDs or power transistors dissipate heat efficiently.

- Electrical performance: Confirms designs meet specifications across operating temperatures.

- Mechanical fit: Ensures components and layout work seamlessly.

Prototypes are particularly valuable for complex, high-performance designs like multilayer boards that need extensive thermal management.

Accelerating Development with Aluminum PCB Prototypes

Aluminum PCB prototyping plays a central role in accelerating electronic product development. By transforming early design concepts into functional test boards, engineers can verify performance parameters long before full-scale manufacturing begins. This approach eliminates design guesswork, shortens validation cycles, and ensures every production run starts from a proven foundation. Rapid prototyping enables:

- Thermal evaluation and optimization – Early prototypes allow real-time measurement of heat dissipation and junction temperature, helping engineers fine-tune copper thickness, via design, and component placement for optimal thermal flow.

- Electrical performance testing – Engineers can analyze voltage drops, EMI behavior, and impedance control under realistic load conditions, making it easier to meet high-speed and power requirements.

- Material and layer stack validation – Testing different substrate combinations or dielectric thicknesses ensures that the final aluminum PCB meets mechanical stability and electrical insulation needs.

- Design iteration at speed – Fast turnaround times mean multiple design variants can be tested in parallel, reducing time-to-market for new product introductions.

- Manufacturability verification – Prototype builds reveal assembly challenges such as solderability, pad alignment, or drilling precision, allowing DFM improvements before mass production.

In advanced applications, aluminum PCB prototypes can also be integrated with flex and rigid-flex structures, combining aluminum’s strength and thermal conductivity with flexible interconnections for compact, heat-efficient designs used in LED lighting, automotive control systems, and high-density power modules.

By closing the loop between design, testing, and manufacturing, Aluminum PCB prototyping transforms development from a linear process into a fast, data-driven workflow—helping engineers deliver better products, faster and more reliably.

Aluminum PCB Prototyping Process

The prototyping process includes:

- Design and Review: Engineers prepare Gerber files and verify layouts using professional Gerber viewing tools.

- Material Procurement: Specialized aluminum substrates are selected based on thermal needs.

- Fabrication: Includes copper cladding, etching, and drilling, with precision equipment ensuring prototype quality.

- Assembly and Testing: SMT or manual assembly of components, followed by functional and thermal testing.

Typical lead times range from 5 to 10 business days, depending on design complexity.

Technical Challenges in Aluminum PCB Prototyping

Aluminum PCBs present unique challenges:

- Thermal Expansion Mismatch: Differences in thermal expansion between aluminum and copper can cause mechanical stress, leading to solder joint fatigue.

- Precision Drilling: Aluminum's hardness requires special equipment to ensure clean, high-quality drilling without affecting electrical performance.

- Soldering: Aluminum’s high thermal conductivity can interfere with soldering. Proper preheating and solder profile adjustments are necessary for reliable connections, especially in high-density interconnect boards.

Best Practices for Aluminum PCB Prototyping

Follow these best practices to optimize prototyping:

- Simulate First: Use thermal simulation tools to predict heat distribution and minimize the number of physical prototypes required.

- Material Alignment: Ensure that materials used for prototypes match those intended for production to avoid discrepancies.

- Comprehensive Testing: Include thermal imaging, temperature cycling, and environmental stress testing to ensure the prototype meets all performance criteria.

- Parallel Prototyping: Order multiple variants of prototypes (e.g., different copper thicknesses or dielectric materials) to test key parameters simultaneously.

Applications for Aluminum PCB Prototypes

Aluminum PCB prototypes are widely used in sectors that demand reliable thermal conductivity, mechanical stability, and high power performance. Typical applications include:

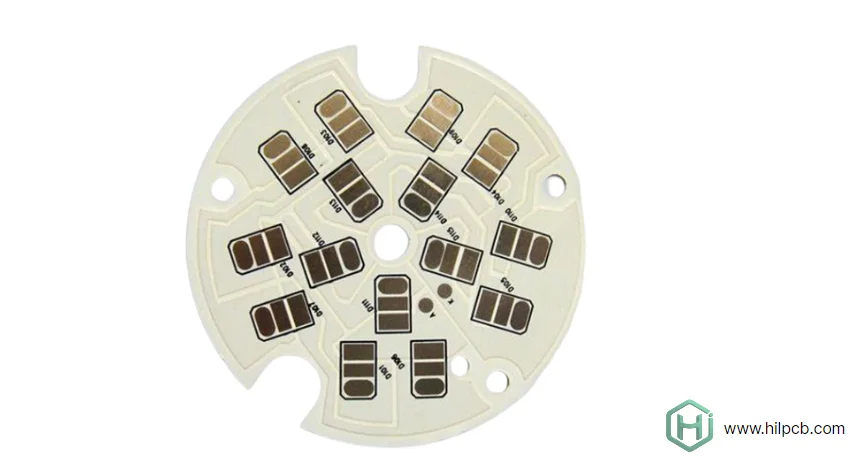

- LED Lighting Systems – streetlights, automotive headlights, display backlights, UV lamps, and architectural lighting.

- Automotive Electronics – EV battery management, motor drivers, power converters, and smart lighting modules.

- Power Supply and Industrial Equipment – AC/DC converters, inverters, rectifiers, and industrial power control systems.

- Consumer Electronics – audio amplifiers, gaming consoles, power banks, and home automation devices.

- Telecommunication Hardware – RF amplifiers, base station modules, signal transmitters, and network power boards.

- Medical Devices – diagnostic imaging systems, patient monitoring devices, and portable medical instruments.

- Renewable Energy Systems – solar inverters, wind power converters, and energy storage controllers.

- Military and Aerospace Electronics – radar systems, avionics modules, and ruggedized communication boards.

- Instrumentation and Sensors – thermal detectors, motion sensors, and precision measurement circuits.

- Industrial Automation – robotic drives, motor controllers, and high-efficiency process control units.

Choosing the Right Prototype Service Provider

To ensure successful prototyping:

- Expertise: Choose a supplier with experience in metal-core PCB fabrication.

- Quality Control: Ensure the supplier has robust inspection protocols and testing capabilities.

- Lead Time: Select a provider with the flexibility to meet tight development schedules.

- Engineering Support: Look for partners offering design consultation and problem-solving throughout the prototyping process.

If you're looking for a reliable partner, turnkey PCB solutions are a great option, as they offer seamless integration of design, fabrication, and testing.

Conclusion

Aluminum PCB prototyping isn’t just about testing — it’s about building confidence before full-scale production. By verifying thermal performance, material reliability, and manufacturability early, you can dramatically reduce risks and accelerate your product launch.

HILPCB Factory provides one-stop PCB solutions — from aluminum PCB fabrication and component sourcing to precision assembly and functional testing. Our engineering team ensures every prototype meets your performance and budget goals, while our advanced facilities guarantee consistency when scaling from prototype to production.

Whether you’re developing LED lighting, automotive modules, or high-power electronics, HILPCB delivers the manufacturing expertise and speed you need to move forward with confidence.