Selecting an aluminum PCB supplier is not just about sourcing a single board type — it’s about finding a long-term manufacturing partner who can support the full spectrum of your electronic product needs. At HILPCB, we serve as a comprehensive PCB and PCBA manufacturer, offering solutions that go beyond aluminum boards — including FR4 PCBs, multilayer boards, HDI, flex-rigid, and ceramic PCBs.

For OEMs and design houses, partnering with a reliable supplier ensures consistent quality, technical collaboration, and scalable production across multiple technologies.

Why Partnering with the Right Aluminum PCB Supplier Matters

Working with an experienced aluminum PCB manufacturer minimizes design risks, reduces costs, and accelerates your product’s time to market. A qualified aluminum PCB supplier in China provides more than fabrication — they deliver engineering insight, advanced process control, and scalable capacity.

Key benefits include:

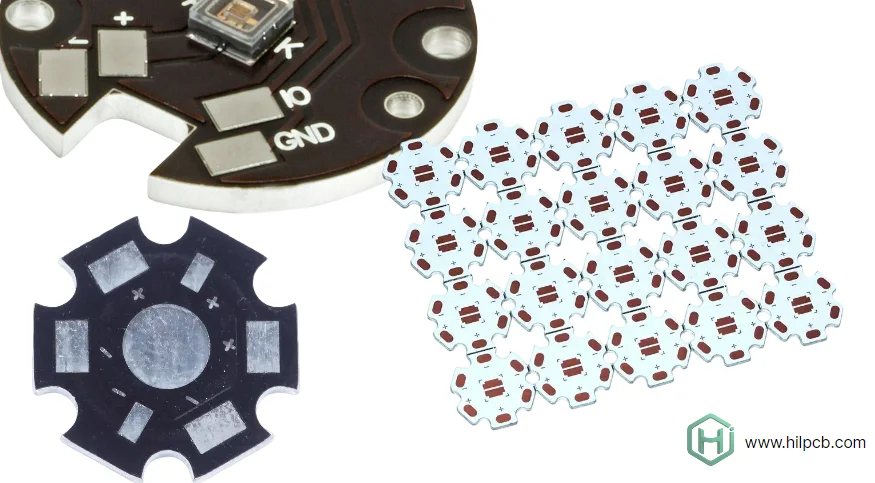

- Thermal reliability – Ensures consistent heat dissipation across applications like LEDs and power systems, similar to high-thermal PCBs.

- Manufacturing precision – Guarantees tight tolerance control and repeatability across single and double-layer PCB designs.

- Engineering collaboration – Offers proactive feedback to optimize manufacturability, often using FR4 PCB and metal-core hybrid configurations.

- Stable supply chain – Reduces delays through efficient production and logistics networks.

With HILPCB, customers benefit from over a decade of experience producing high-performance aluminum PCBs for global industries.

How to Evaluate a Reliable Aluminum PCB Supplier

Choosing a supplier isn’t just about pricing. Look for manufacturers who demonstrate proven expertise, strong quality systems, and transparent communication.

- Technical Expertise – A capable supplier can fabricate single-layer, multilayer, and hybrid metal-core boards. They should also offer insight into material selection and thermal stack design, comparable to multilayer PCB standards.

- Quality Certification – Certifications such as ISO 9001, IATF 16949, and UL Recognition show commitment to reliability and international standards.

- Equipment and Process Control – Evaluate whether your supplier uses automated optical inspection (AOI), flying probe testing, and controlled lamination systems as used in HDI PCB production.

- Scalability – Ensure your supplier can handle both small prototype batches and large production runs with consistent quality.

- Communication and Support – Effective suppliers offer real-time updates and dedicated engineering assistance.

As a China-based aluminum PCB supplier, HILPCB provides global clients with advanced fabrication lines, strict process management, and comprehensive testing to guarantee every board meets performance targets.

Quality Management: The Foundation of a Reliable Aluminum PCB Manufacturer

Quality control defines a supplier’s reliability. At HILPCB, every step — from raw material inspection to final testing — follows a documented quality process.

- Incoming Material Verification – All aluminum substrates and copper foils undergo thermal conductivity and dimensional testing.

- In-Process Inspection – Automated monitoring of etching, plating, and drilling ensures precision and stability for heavy copper PCB applications.

- Electrical & Thermal Testing – Each board is tested for continuity, impedance, and heat dissipation performance.

- Traceability and Reporting – Every order includes detailed QC documentation for full transparency.

Strong quality management minimizes field failures, enhances reliability, and protects your brand reputation.

Certifications & Capabilities of Top Aluminum PCB Suppliers

When evaluating global suppliers, certifications tell you how robust their systems are. HILPCB maintains international certifications that meet diverse industry needs:

- ISO 9001 – Quality Management System

- IATF 16949 – Automotive PCB manufacturing compliance

- UL Recognition – Verified electrical safety performance

- RoHS & REACH Compliance – Environmental responsibility standards

We also specialize in advanced materials such as high-frequency PCB, ceramic PCB, and Teflon PCB, serving industries where performance and precision are critical.

These qualifications make HILPCB a trusted aluminum PCB supplier in China for high-demand industries including automotive, telecommunications, and renewable energy.

Cost, Lead Time, and Global Delivery

Working with a professional supplier means gaining both competitive pricing and predictable delivery schedules. HILPCB balances cost efficiency with process precision to ensure fast turnaround and consistent results.

- Transparent Pricing – Detailed cost breakdowns for materials, fabrication, and testing.

- Volume Flexibility – Optimized pricing for prototypes, small runs, and mass production.

- Rapid Turnaround – Standard lead times from 5 to 10 days, with expedited options available.

- Worldwide Logistics – Reliable delivery via global courier partners and customs-ready documentation.

We also provide complete assembly solutions including SMT assembly, turnkey assembly, and box-build assembly, enabling one-stop service from PCB fabrication to final product integration.

Building Long-Term Supplier Partnerships

Sustainable cooperation goes beyond transactions. The best suppliers align with your technical roadmap and provide continuous support throughout product evolution.

At HILPCB, partnership means:

- Continuous Improvement – Regular process upgrades and efficiency innovations.

- Confidentiality & IP Protection – NDA-backed data security and information management.

- Dedicated Support – Direct communication with engineers and project managers.

- Sustainability Commitment – Environmentally responsible production and ethical business practices.

Such partnerships foster innovation, reduce risk, and enable faster product iterations.

Simplifying Collaboration with Digital Tools

Modern PCB manufacturing thrives on collaboration and data accuracy. HILPCB integrates digital platforms that streamline communication and technical exchange.

- Online Quotation System – Submit your files and receive instant pricing.

- Gerber & BOM Viewer Tools – Review and validate your designs using our Gerber Viewer and BOM Viewer.

- Cloud Project Tracking – Monitor production progress and testing results in real time.

These tools enhance efficiency and help global teams maintain visibility from prototype to mass production.

Conclusion

Finding the right aluminum PCB supplier is a key step toward ensuring reliable thermal management and product performance — but the ideal partner should also be capable of supporting your broader PCB and assembly requirements.

At HILPCB, we manufacture a wide range of printed circuit boards — from standard FR4 and HDI to metal-core, ceramic, and flex-rigid PCBs — all supported by in-house SMT and turnkey assembly services. This integrated capability allows our clients to streamline supply chains, improve cost control, and ensure seamless collaboration from prototype through full-scale production.

By partnering with HILPCB, you gain more than a supplier — you gain a technical ally committed to delivering precision, reliability, and long-term value across every PCB type your project requires.