The performance of any metal core PCB is largely determined by the choice of aluminum substrate materials. While designers focus on circuit layout, factors such as aluminum alloy composition, dielectric properties, and surface treatments directly impact thermal efficiency, electrical isolation, and long-term reliability.

Beyond thermal conductivity, other material characteristics—such as dielectric thickness, breakdown voltage, coefficient of thermal expansion, and mechanical strength—play a key role in both performance and cost. A deep understanding of these factors ensures optimal material selection, balancing performance with budget.

At HILPCB, our materials engineering team collaborates with top substrate suppliers to source the best solutions for your needs. With our PCB manufacturing expertise and extensive materials knowledge, we help you select substrates that deliver optimal performance at the best cost.

Dielectric Layer Materials

The dielectric layer creates the critical interface between electrically active copper circuits and the grounded aluminum base. This thin layer (50–200 µm) must simultaneously provide high thermal conductivity, electrical isolation, mechanical adhesion, and CTE compatibility.

Polymer Matrix Systems

Epoxy-Based Dielectrics – The most common matrix material provides good adhesion, manufacturing reliability, and cost-effectiveness. Standard epoxy systems achieve 1.5–2.0 W/mK thermal conductivity when filled with 50–70% ceramic particles. Curing temperatures of 150–180°C suit standard PCB lamination equipment.

Polyimide-Based Dielectrics – High-temperature applications exceeding 150°C continuous operation may require polyimide matrix materials. These specialty resins maintain properties at temperatures up to 200–250°C but cost 2–3× more than epoxy systems. Use only when operating temperature justifies the premium.

Silicone-Based Dielectrics – Offer excellent flexibility and low-temperature performance down to -60°C for applications requiring mechanical compliance. Thermal conductivity typically ranges 2–3 W/mK. Common in outdoor electronics and automotive applications with extreme temperature cycling.

Ceramic Filler Materials

Thermal conductivity of the dielectric layer depends primarily on ceramic filler content and particle properties:

Alumina (Al₂O₃) – The standard filler material for thermal dielectrics. Aluminum oxide particles offer good thermal conductivity (30 W/mK), excellent electrical insulation, and low cost. Filler loading of 50–70% by weight achieves dielectric thermal conductivity of 1.5–2.0 W/mK.

Aluminum Nitride (AlN) – Premium filler material with thermal conductivity of 200+ W/mK enables dielectric layers achieving 3–5 W/mK. The 2–3× cost premium over alumina-filled systems is justified when thermal performance is critical. Aluminum circuit board designs using AlN dielectrics achieve significantly lower thermal resistance.

Boron Nitride (BN) – Offers thermal conductivity similar to AlN (250+ W/mK) with superior electrical properties and lower density. More expensive than AlN but used in specialized aerospace and military applications where weight or electrical performance justifies the cost.

Silicon Carbide (SiC) – Very high thermal conductivity (120 W/mK) but slightly conductive, limiting use in high-voltage applications. Particle hardness increases manufacturing complexity and tool wear during drilling operations.

Thermal Interface Treatment

The interface between aluminum substrate and dielectric layer critically affects thermal performance and long-term reliability:

Surface Preparation Methods

Chemical Conversion Coating – Chromate or zirconium-based chemical treatment creates a thin conversion layer (1–3 µm) that improves adhesion and prevents oxidation. Standard process for aluminum board manufacturing provides consistent, reliable results at low cost.

Anodizing – Electrochemical process creates a thicker (5–25 µm) aluminum oxide layer with excellent corrosion protection and adhesion properties. Type II sulfuric acid anodizing is most common. Type III hard anodizing provides enhanced wear resistance for applications with mechanical demands.

Mechanical Roughening – Abrasive blasting or brushing creates surface texture promoting mechanical interlocking with the dielectric. Used in conjunction with chemical treatments for critical adhesion requirements. Excessive roughness can reduce effective thermal contact area.

Plasma Treatment – Surface cleaning and activation using atmospheric or vacuum plasma removes organic contamination and creates chemically active sites for enhanced bonding. Aerospace and military applications may specify plasma treatment for maximum reliability assurance.

Coefficient of Thermal Expansion Matching

CTE mismatch between materials generates mechanical stress during temperature changes. The magnitude of stress depends on temperature change, CTE difference, material elastic modulus, and layer geometry.

Material CTE Values

| Material | CTE (ppm/°C) |

|---|---|

| Aluminum 5052 | 23.8 |

| Aluminum 6061 | 23.6 |

| Copper | 16.5 |

| Epoxy dielectric | 30–60 |

| Polyimide dielectric | 20–40 |

| FR4 (z-axis) | 70–90 |

Aluminum's CTE (24 ppm/°C) matches copper (17 ppm/°C) reasonably well—much better than FR4's z-axis CTE (70+ ppm/°C). This gives aluminum base PCB constructions inherently better thermal cycling reliability than multilayer FR4.

The dielectric layer's CTE typically exceeds both copper and aluminum. Filled systems using ceramic particles reduce polymer CTE toward metal values. Higher filler loading improves CTE matching but increases material cost and viscosity, complicating manufacturing.

Design Mitigation Strategies

Material Selection – Specify low-CTE dielectrics (polyimide or highly-filled epoxy) for applications with wide temperature excursions (-40 to +125°C automotive) or critical reliability requirements (medical, aerospace).

Trace Orientation – Orient long, narrow traces parallel to expected expansion directions when possible. Avoid traces perpendicular to expansion that may crack under stress during thermal cycling.

Stress Relief Features – Rounded corners, trace meandering, and teardrops at pad entries reduce stress concentration. Avoid sharp angles and abrupt geometry changes in copper patterns.

Thermal Cycling Qualification – Test assemblies through expected temperature range for 500–1000 cycles minimum per IPC-9701 standards. Monitor electrical continuity and cross-section samples for crack initiation.

Application-Based Selection Matrix

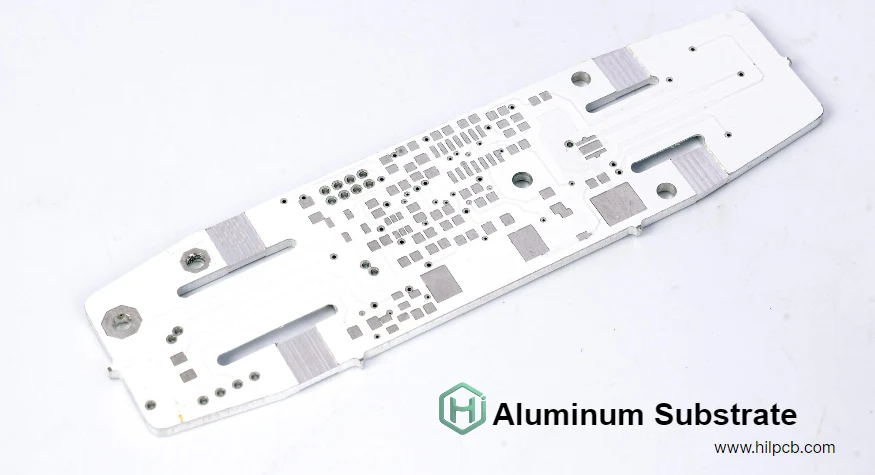

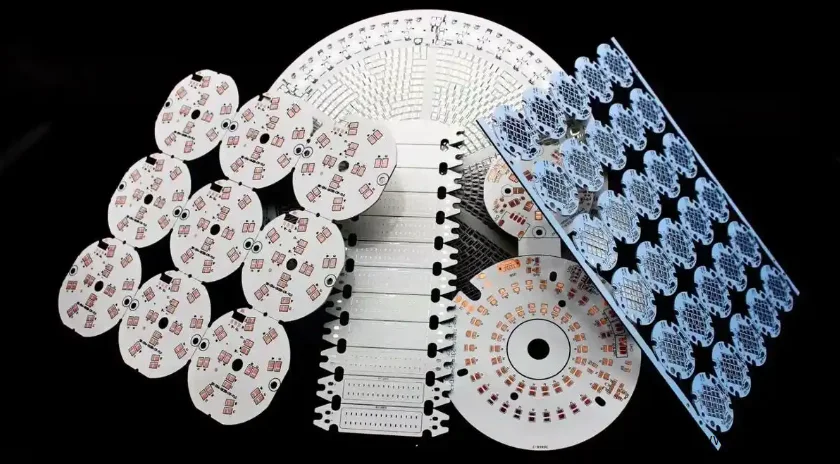

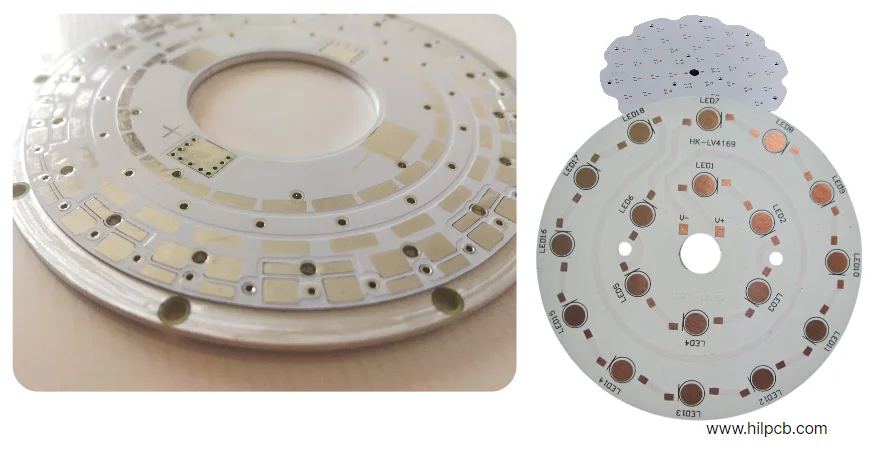

LED Lighting (1–5 W/cm²) – Standard 5052 aluminum with 1.5–2.0 W/mK dielectric, 100–150µm thickness. White solder mask for optical efficiency. Cost-optimized solution for majority of LED applications.

Automotive Electronics – 5052 or 6061 aluminum depending on mechanical requirements. Standard to high-performance dielectric (2–4 W/mK) based on power levels. Wide temperature range (-40 to +125°C) demands robust materials and processes.

Power Electronics (3–10 W/cm²) – 6061 aluminum for mechanical stability with 3–4 W/mK high-performance dielectric. Consider integration with heavy copper PCB for combined electrical and thermal performance. Thick substrates (2.0–3.0mm) improve heat spreading.

RF/Microwave – Aluminum substrate provides stable ground plane and mechanical rigidity. Standard dielectric sufficient unless high power (>50W). CTE stability critical for high-frequency performance maintenance across temperature.

Industrial/Medical – 5052 aluminum with standard dielectric balances cost and performance. Long-term reliability requires attention to material quality and process control. UL recognition and material certifications support regulatory compliance.

Working with HILPCB Materials Engineering

Our materials engineers provide comprehensive support throughout the design process:

Thermal Analysis – Finite element modeling predicts junction temperatures for different material combinations. Identifies the most cost-effective substrate meeting thermal requirements without over-specification.

Material Sourcing – Direct relationships with leading substrate manufacturers (Bergquist, Denka, Polytronics) ensure access to latest materials and competitive pricing for both prototype and production volumes.

Custom Specifications – Special applications may require non-standard dielectric thickness, custom aluminum alloys, or specialized surface treatments. Our PCB manufacturing team qualifies custom materials when justified by application requirements.

Documentation Support – Complete material traceability with thermal conductivity test data, dielectric breakdown voltage reports, CTE measurements, and composition certifications. Support customer qualification processes and regulatory submissions.

All metal core PCB materials undergo incoming inspection verifying thermal conductivity, dielectric strength, and dimensional specifications before entering production.

FAQ

Q1: How can I verify the thermal conductivity of my aluminum substrate before purchasing?

You can verify the thermal conductivity of aluminum substrates by requesting material certificates from suppliers, which should comply with ASTM D5470 or ISO 22007-2 standards. At HILPCB, we perform thorough inspections on all aluminum substrates to ensure they meet specified thermal and mechanical performance standards before production.

Q2: What is the role of aluminum substrates in improving the reliability of LED PCB designs? Aluminum substrates are widely used in LED PCB designs due to their ability to rapidly dissipate heat, which is essential for maintaining the longevity and performance of high-power LEDs. By improving heat management, aluminum PCBs help extend the lifespan of LED modules and reduce the risk of thermal failure.

Q3: What thermal conductivity should I specify for aluminum substrates in high-power LED applications? For high-power LED applications, aluminum substrates with a dielectric layer that provides thermal conductivity between 3–5 W/mK are typically ideal. This ensures sufficient heat dissipation to maintain safe operating temperatures and extend the lifespan of the LEDs.

Q4: How do aluminum PCB substrates compare to copper substrates in terms of thermal management? While copper substrates provide superior thermal conductivity (400 W/mK), aluminum substrates are a more cost-effective option with excellent thermal performance for most applications, providing around 170–180 W/mK thermal conductivity. Aluminum PCBs are a popular choice for thermal management in many industries due to their balance of performance and affordability.