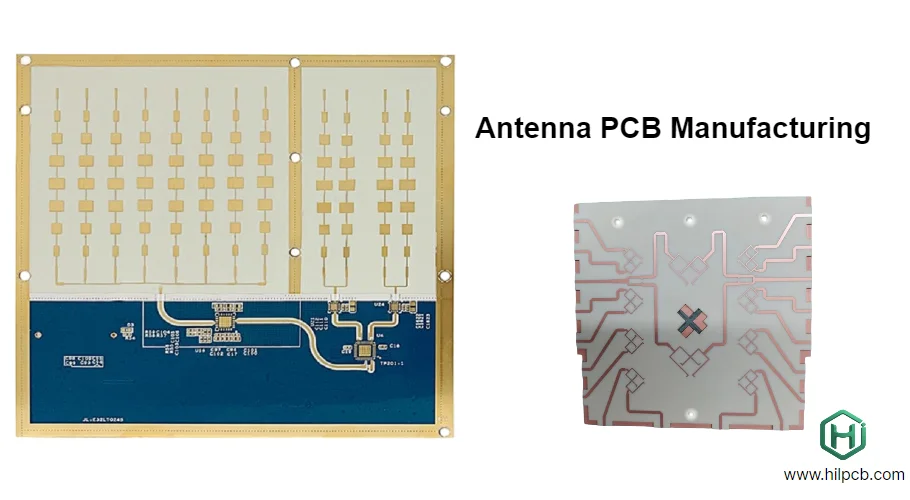

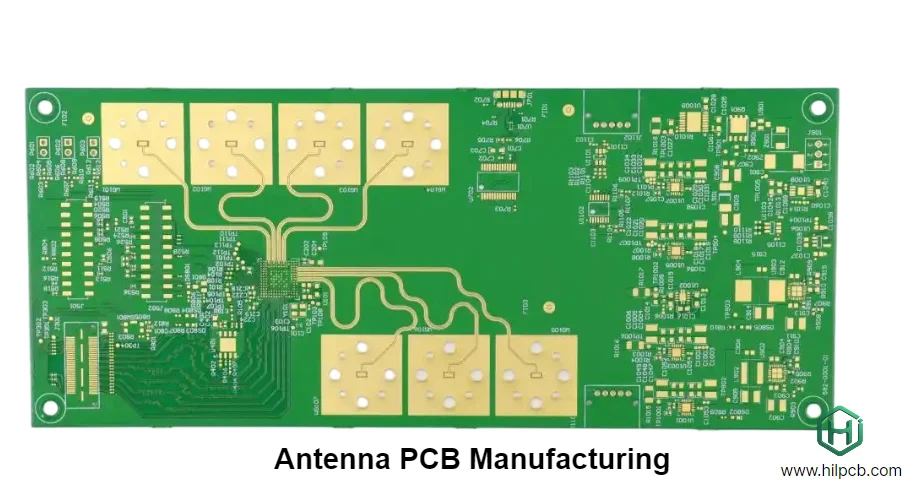

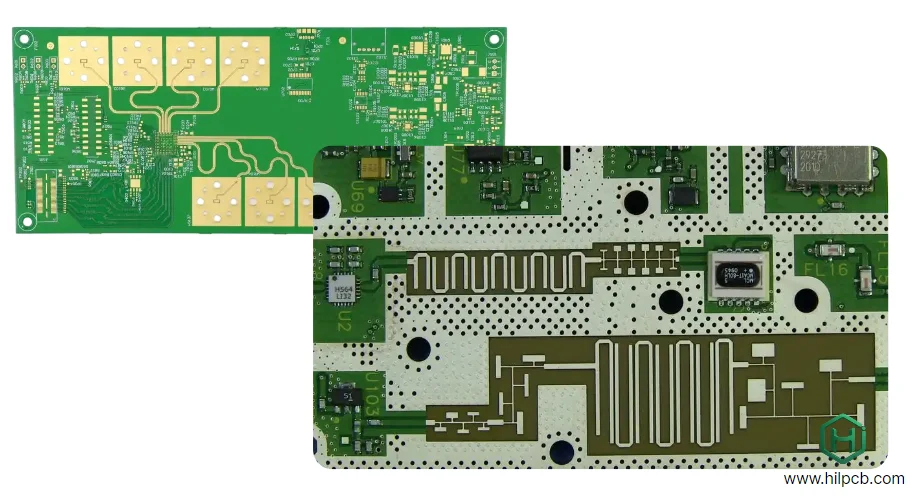

Antenna PCB technology integrating radiating elements directly onto circuit boards has revolutionized wireless device design by eliminating costly external antennas, reducing assembly complexity, and enabling compact form factors. At HILPCB, we are a full-service PCB manufacturing and assembly factory specializing in antenna PCB solutions for 5G, WiFi, Bluetooth, cellular, GPS, LoRa, IoT, automotive radar, satellite communications, medical devices, and industrial wireless applications spanning 700MHz to 60GHz frequency ranges.

Our comprehensive antenna PCB services include high-frequency substrate materials optimized for antenna efficiency, multilayer PCB constructions with integrated ground planes, precision impedance control for antenna feed networks, and complete turnkey assembly with RF testing and validation.

Antenna PCB Design Topologies and Applications

Understanding different antenna PCB architectures helps you choose the right design for your specific wireless application needs in consumer electronics, industrial systems, automotive, medical devices, and aerospace.

Microstrip Patch Antennas These are the most common antenna PCB types used in compact wireless devices. They are characterized by a rectangular or circular metal patch on a dielectric substrate over a ground plane. Typically used in the 1GHz to 100GHz range, with the most common frequencies being 2-6GHz (WiFi/5G). Microstrip patch antennas are popular due to their low profile, ease of fabrication, and cost-effectiveness. Applications include WiFi routers, 5G smartphones, GPS modules, IoT sensors, and medical monitors.

Inverted-F Antennas (IFA) and Planar IFA (PIFA) Inverted-F antennas and planar inverted-F antennas are compact, space-efficient designs commonly used in mobile devices. These antennas are designed as quarter-wave monopoles folded with a shorting post or strip. They operate typically from 700MHz to 6GHz and are widely used in smartphones, tablets, wearables, and cellular IoT modules.

Monopole and Dipole Antennas on PCB Monopole and dipole antennas offer simple omnidirectional coverage patterns, making them ideal for wide-area communication. These designs are often found in sub-1GHz IoT devices (like LoRa, Sigfox), WiFi, Bluetooth, and RFID readers. Monopoles require a ground plane, and dipoles are either balanced or use a balun for impedance matching.

Chip Antennas with PCB Integration These are miniature ceramic antennas integrated directly onto the PCB, making them ideal for space-constrained applications. With frequency ranges from 700MHz to 6GHz, they are commonly used in wearables, medical implants, asset trackers, and IoT devices. Chip antennas offer a compact solution with excellent performance consistency and are often preferred for their small size.

Array Antennas for 5G and Radar Array antennas incorporate multiple radiating elements with phase control to enable beamforming and spatial multiplexing (MIMO). These are essential in 5G base stations, automotive radar, and satellite terminals. Operating in frequencies like 3.5GHz, 28GHz, and 77GHz, array antennas deliver high gain and precise beam steering capabilities, making them indispensable in modern communication and radar systems.

Conformal and 3D Antennas Conformal antennas are designed to follow curved surfaces, ideal for integration into products like aerospace systems, automotive body-integrated antennas, and curved wearables. These antennas often require specialized rigid-flex PCBs and thermoformed PCBs to ensure they conform to the desired shape without compromising performance.

Design Considerations and Materials For each of these antenna types, the choice of materials (such as Rogers materials, PTFE, and Teflon) and design considerations (like impedance matching and ground plane size) are crucial to optimize performance. The right choice ensures efficient signal transmission, minimal loss, and reliable operation across various frequency ranges and application environments.

High-Frequency Materials for Antenna PCB

Material selection critically impacts antenna efficiency, bandwidth, and production consistency. Our material expertise ensures optimal performance-cost balance.

Rogers High-Frequency Laminates: Industry-standard materials for demanding antenna applications:

RO4350B (Dk 3.48 ±0.05, Df 0.0037 @ 10GHz):

- Most popular choice balancing performance and processability

- Compatible with standard FR4 fabrication processes (no special drilling/routing)

- Ideal for 2.4GHz/5GHz WiFi, 3.5GHz 5G, GPS (1.5GHz), Bluetooth

- Operating range: DC to 40GHz

- Typical applications: Dual-band WiFi routers, 5G smartphones, automotive V2X, medical telemetry

- Cost: ~4× FR4 premium but 35% lower than PTFE laminates

RO4003C (Dk 3.38 ±0.05, Df 0.0027 @ 10GHz):

- Lower Dk than RO4350B, useful for physically larger antennas or wider bandwidth

- Excellent loss tangent for maximum efficiency above 2GHz

- Same processability as RO4350B

- Applications: High-performance 5GHz WiFi, 5G mmWave, satellite communications

- Cost: Similar to RO4350B

RO3003 (Dk 3.00 ±0.04, Df 0.0013 @ 10GHz):

- Lowest loss for mmWave applications (24GHz, 28GHz, 77GHz)

- PTFE-based requiring specialized processing

- Essential for automotive radar, 5G mmWave base stations, satellite ground terminals

- Operating range: DC to 77GHz

- Cost: ~8× FR4 premium

- Lead time: Longer due to specialized processing

Taconic RF Laminates: Alternative high-frequency materials with competitive performance:

TLY-5 (Dk 2.20 ±0.02, Df 0.0009 @ 10GHz):

- Very low Dk for wide bandwidth and large antenna structures

- Ultra-low loss for maximum efficiency

- Applications: Wideband communications, radar, aerospace

- Cost: Premium pricing similar to Rogers RO3003

RF-35 (Dk 3.50 ±0.05, Df 0.0025 @ 2.5GHz):

- Performance comparable to Rogers RO4350B

- Cost-effective alternative with similar fabrication processes

- Good choice for 2.4GHz/5GHz WiFi applications

FR4 and Modified FR4: Cost-effective solutions for lower-frequency or budget-sensitive applications:

Standard FR4 (Dk 4.2-4.8, Df 0.015-0.020):

- Acceptable for 2.4GHz single-band WiFi, Bluetooth, sub-1GHz IoT

- Major disadvantages: Wide Dk tolerance (±10%) causes frequency shift, High Df reduces efficiency 10-15% vs Rogers

- Cost advantage: Baseline material cost

- Applications: Consumer Bluetooth devices, short-range WiFi, LoRa nodes

- Typical efficiency: 50-60% at 2.4GHz (vs 65-70% with Rogers)

High-Tg FR4 (Dk 4.0-4.5, Df 0.012-0.018, Tg >170°C):

- Improved thermal stability for automotive or industrial environments

- Slightly better loss tangent than standard FR4

- Applications: Industrial wireless sensors, automotive Bluetooth/WiFi (non-critical)

- Cost: +10-20% vs standard FR4

Hybrid Stackup Strategies: Cost optimization without sacrificing antenna performance:

Rogers + FR4 Multilayer:

- Use Rogers for antenna layer(s), FR4 for internal signal/power layers

- Reduces total material cost 40-60% vs all-Rogers construction

- Example: 4-layer with Rogers outer layers, FR4 inner layers

- Maintains antenna efficiency while lowering stackup cost

- Our specialty for cost-conscious high-performance designs

Rogers Core with FR4 Prepreg:

- Rogers core for antenna and controlled impedance, FR4 prepreg for bonding

- Achieves 30-50% cost reduction vs all-Rogers

- Common in 5G smartphones and WiFi 6 routers

Localized Rogers Regions:

- Rogers material only in antenna footprint, FR4 for rest of PCB

- Requires advanced fabrication but maximizes cost savings

- Best for large PCBs with small antenna area (<10% of total)

Material Selection Guidelines:

- Sub-1GHz IoT (LoRa, Sigfox): FR4 acceptable, high-Tg FR4 for harsh environments

- 2.4GHz Single-Band (Bluetooth, WiFi 4): FR4 for consumer, Rogers for extended range

- 2.4GHz + 5GHz Dual-Band (WiFi 5/6): Rogers RO4350B or RO4003C strongly recommended

- 5GHz Only (WiFi 6): Rogers RO4350B/RO4003C or Taconic RF-35

- 6GHz (WiFi 6E): Rogers RO4350B minimum, RO4003C for best efficiency

- 3.5GHz 5G: Rogers RO4350B standard choice

- mmWave 5G/Radar (24-77GHz): Rogers RO3003 or Taconic TLY-5 required

Impedance Control and RF Design Considerations

Precise impedance matching throughout the antenna feed network maximizes radiated power and minimizes VSWR.

Controlled Impedance Fabrication: Our standard antenna PCB controlled impedance capabilities:

- 50Ω Microstrip/Stripline: ±5Ω tolerance (±10%) standard, ±2.5Ω (±5%) available

- Differential Pairs: 90Ω, 100Ω common for balanced feeds

- Trace Width Tolerance: ±0.025mm for RF traces (tighter than ±0.05mm standard)

- Dielectric Thickness Control: ±0.025mm (±10%) for consistent impedance

- Stackup Documentation: Detailed stackup with Dk, thickness, copper weight provided

- TDR Testing: Time-domain reflectometry verification for critical designs

Design Rules for Antenna PCB:

- Ground Plane Clearances: 3× trace width minimum around antenna radiators

- Via Stitching: Ground vias spaced <λ/20 around antenna perimeter (e.g., <6mm @ 2.4GHz)

- Component Placement: Keep components >5mm from radiating elements to avoid detuning

- Trace Routing: Avoid routing signals under or near antenna area

- Solder Mask: Remove from radiating elements and feed points (adds Dk variation, 0.015mm thickness affects tuning)

Matching Network Design: Converting 50Ω feed to antenna impedance (typically 30-75Ω):

L-Section Matching: Simplest, 2 components (series inductor + shunt capacitor or vice versa)

- Narrow bandwidth (typically 5-10%)

- Used for single-frequency designs (GPS 1.5GHz, single WiFi band)

- Component values: 1.0-10nH inductors, 0.5-5pF capacitors typical

π-Network Matching: Three components (C-L-C or L-C-L)

- Wider bandwidth (10-20%) for dual-band or broadband designs

- More degrees of freedom for optimization

- Common for 2.4GHz + 5GHz dual-band WiFi

- Enables Q-factor control for bandwidth tuning

Component Tolerances: 1% or 2% precision components recommended

- 5% tolerances cause ±0.3dB VSWR variation

- Critical for production consistency

- Use 0402 or 0201 size for minimal parasitic inductance

Smith Chart Optimization: We use network analyzer measurements and Smith chart analysis to:

- Visualize impedance transformation through matching network

- Identify optimal matching topology (L-section vs π-network)

- Select component values for minimum VSWR across operating bandwidth

- Iterate design until VSWR <2:1 achieved across entire band

Complete Antenna PCB Assembly Services

From bare PCB fabrication through fully tested assemblies, our turnkey antenna PCB services include:

PCB Fabrication Capabilities:

- Layer Count: 1-16 layers, most antenna designs use 2-4 layers

- PCB Size: 10mm × 10mm minimum (chip antenna modules) to 500mm × 500mm (antenna arrays)

- Minimum Trace/Space: 0.075mm/0.075mm (3mil/3mil) for fine-pitch RF routing

- Surface Finish: ENIG (gold) standard for solderability and RF performance, immersion silver for cost reduction

- Panelization: Multiple small antenna PCBs per panel for cost-effective prototyping

SMT Assembly with RF Expertise:

- Component Placement Accuracy: ±0.03mm for matching network precision

- AOI (Automated Optical Inspection): 100% inspection verifies component values and orientation

- RF Connector Soldering: SMA, U.FL, IPX connectors installed with controlled impedance transitions

- Reflow Profiling: Optimized profiles prevent Rogers material degradation

- Volume Capacity: Large volume assembly up to 50,000 units per month

Antenna Testing and Validation: Critical measurements ensure your antenna meets specifications:

S-Parameter Testing:

- Equipment: Vector Network Analyzer (VNA), DC to 6GHz standard, 67GHz available

- Measurements: S11 (return loss), input impedance, VSWR

- Acceptance Criteria: Typically S11 <-10dB (VSWR <2:1) across operating band

- Testing Fixtures: Custom PCB fixtures with SMA transitions calibrated for accurate measurements

- Calibration: Daily VNA calibration ensures ±0.1dB measurement accuracy

Far-Field Pattern Testing:

- Anechoic Chamber: Partner facilities for radiation pattern measurements

- Parameters Measured: Gain (dBi), 3dB beamwidth, front-to-back ratio, polarization

- Frequency Sweep: Full pattern across operating bandwidth

- Applications: Directional antennas, arrays, certification requirements

OTA (Over-The-Air) Testing for Cellular:

- TRP (Total Radiated Power): Sum of power radiated in all directions

- TIS (Total Isotropic Sensitivity): Antenna receiving sensitivity averaged over sphere

- Certification: Required for PTCRB (North America), GCF (global) cellular device approval

- Partner Network: We coordinate OTA testing at certified labs

Production Testing:

- 100% S11 Testing: Every production unit tested on automated fixture

- Test Time: <5 seconds per unit using rapid VNA sweep

- Statistical Process Control: Resonant frequency and VSWR monitored for process drift

- Reject Rate: <1% typical with proper design and process control

- Documentation: Certificate of Conformance with test data for traceability

Why Choose HILPCB for Antenna PCB Manufacturing

At HILPCB, we bring over 15+ years of expertise in antenna PCB manufacturing, ensuring high-performance wireless solutions across various industries. We offer comprehensive engineering support throughout the design and manufacturing process, helping you select the right antenna type, optimize performance, and address any design challenges. Our services include free antenna simulation, DFM analysis, and impedance matching network design to ensure your antenna PCB meets the highest standards.

We provide material selection guidance tailored to your application. Our expertise spans a range of high-frequency substrates, including Rogers, Taconic, and Isola materials. We offer hybrid stackup designs to cut costs by 40-60% without sacrificing performance, and evaluate FR4 alternatives for cost-sensitive applications. With our volume pricing and material availability planning, we ensure cost-effective solutions that meet your performance and budget requirements.

From precision fabrication to turnkey solutions, HILPCB ensures consistent quality in every step. We maintain ±5% controlled impedance, precision trace width tolerance, and handle PTFE and ceramic-filled laminates with expertise. Our in-house testing includes S11/VSWR testing, automated production tests, and OTA testing coordination for certification. We offer a fast turnaround with 7-10 days for prototypes and 15-20 days for production, ensuring timely delivery for both low and high-volume projects.