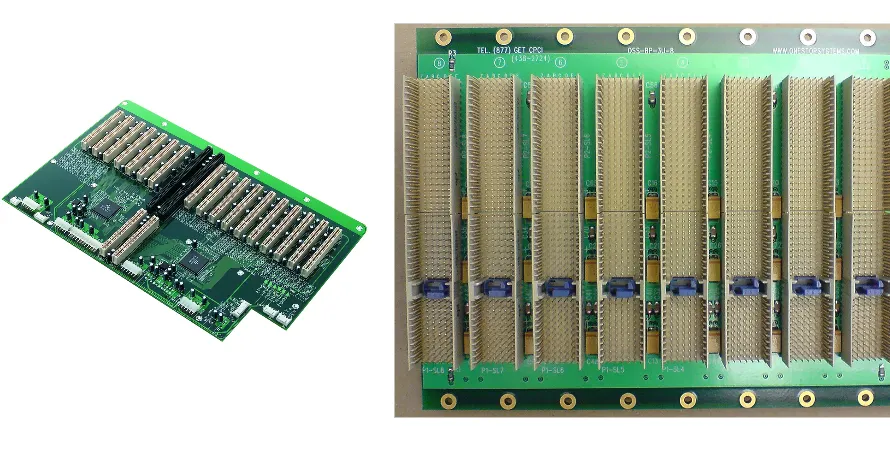

Backplane PCBs are often the backbone of complex systems—handling high-speed data transfer, high layer counts, and demanding mechanical requirements. At Highleap PCB Factory, we specialize in building custom backplane PCBs with precision and speed. For customers requiring reliability in networking, telecom, data centers, and test systems, we offer fast and dependable production capacity for large-format, multi-layer boards.

Explore our product offerings including Backplane PCB capabilities, IC Substrate boards, HDI PCBs, and High-Tg PCBs.

Why Engineers Choose Highleap for Backplane PCB Projects

Our factory is optimized for challenging PCB jobs. When it comes to backplane PCB manufacturing, we support:

- 18–64 layer stack-ups with tight registration

- Controlled impedance for differential pairs and high-speed lanes

- 2 mm+ thick boards with heavy copper

- Long-format panels for connectorized applications

- High-Tg and low-loss substrates like polyimide, Panasonic Megtron, and Rogers

- Mechanical reliability for press-fit and high-insertion connectors

We work with OEMs and system integrators to fabricate high-performance custom backplane PCBs that support real-world signal integrity and long-term mechanical durability.

Technical Layout for Complex Backplane Builds

To highlight how Highleap supports advanced backplane requirements, consider the following structure:

| Capability Area | Technical Features |

|---|---|

| Layer Count | Up to 64 layers with backdrill and sequential lamination |

| Board Size | Extended formats for rack-mounted systems |

| Materials | High-Tg FR4, polyimide, Megtron 6, Rogers 4350B |

| Vias & Drilling | Blind/buried vias, controlled-depth, backdrill, epoxy plug |

| Signal Types | PCIe, XAUI, USB, DDR4, custom bus interfaces |

| Edge Prep | Gold fingers, beveling, press-fit hole support |

These builds are critical for high-speed interconnect backplanes, telecom line cards, test interfaces, and enterprise storage arrays.

Full-Service Backplane PCB Assembly and Logistics

Highleap is more than just a backplane PCB manufacturer—we’re also an experienced backplane PCB assembly provider. For complex systems involving hundreds of components and demanding quality checks, we provide:

- Precise assembly for large-format and heavy boards

- Support for BGA, press-fit, and through-hole insertion

- Automated inspection and optional in-circuit test

- Safe ESD packaging and international shipping

- Flexible invoicing and secure online payments

Before ordering, preview your files using our Gerber Viewer and 3D Viewer to verify alignment and connectivity.

Fast Turnaround with Quality Assurance

Lead time matters. While backplanes are more complex than standard PCBs, we still offer accelerated options:

- Fabrication in as little as 5–8 working days for qualified stack-ups

- Engineering reviews for impedance and thermal performance

- Layer inspection, X-ray, and AOI reporting on request

- Material traceability and production batch documentation

Our goal is to deliver every custom backplane PCB with consistency and zero compromise.

Conclusion

Backplane PCBs define the performance envelope of large systems. Whether you're designing for signal density, mechanical stability, or low-loss transmission, Highleap PCB Factory has the expertise and infrastructure to fabricate and assemble high-layer, high-speed backplanes.

From HDI PCBs to high-Tg laminates to IC substrate integration, we support engineering teams building telecom, datacenter, and instrumentation infrastructure around the world.

Let us help you move from layout to launch—with guaranteed quality, responsive service, flexible payment, and reliable global delivery.