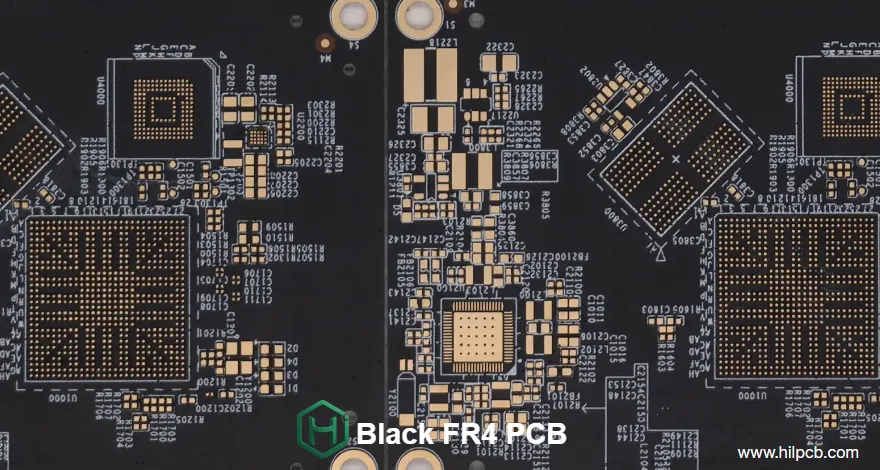

Why Black PCBs Dominate Premium Electronics

Black FR4 PCB has become synonymous with high-end electronics—from flagship smartphones to gaming peripherals. This isn't just marketing; black solder mask delivers specific technical advantages that justify its premium positioning.

The matte black finish absorbs stray light, reducing optical interference in camera modules and sensor applications by up to 70%. For gaming hardware and automotive displays, black PCBs minimize reflections that could distract users or interfere with optical systems.

Thermal Performance Benefits

Black solder mask contains carbon additives that enhance thermal radiation properties:

- Emissivity Factor: 0.90-0.95 vs 0.85 for green FR4 PCB

- Heat Dissipation: 5-8°C lower junction temperatures in LED applications

- Thermal Cycling: Superior performance through 1500+ cycles

- Hot Spot Reduction: More uniform temperature distribution

Manufacturing Challenges and Solutions

Process Complexity

Black solder mask requires specialized handling:

Inspection Difficulty: Standard AOI systems struggle with low contrast between black mask and copper. Solution: High-resolution cameras with specialized lighting angles and AI-enhanced defect detection.

Thickness Control: Carbon additives affect flow characteristics. We maintain ±3μm tolerance through viscosity monitoring and automated coating systems.

Coverage Uniformity: Black mask shows imperfections more readily than green. Multi-pass application ensures complete, even coverage without pinholes.

Quality Control Adaptations

- UV inspection for coverage verification

- Cross-section analysis at 200X magnification

- Adhesion testing per IPC-TM-650

- Ionic contamination testing with specialized parameters

Application-Specific Design Considerations

Gaming and PC Components

Graphics cards and motherboards use black FR4 for aesthetics and performance. The reduced reflectivity prevents light bleed in RGB-illuminated cases. For high-power GPUs, black PCBs contribute to thermal management alongside heatsinks and cooling systems.

Automotive Electronics

Dashboard displays and infotainment systems require black PCBs to prevent reflections on windshields. The enhanced thermal properties benefit power electronics in engine compartments operating at 105°C ambient temperatures.

Premium Audio Equipment

High-end amplifiers utilize black FR4 to minimize EMI and provide visual consistency with aluminum enclosures. The carbon content in black mask provides marginal EMI shielding benefits—approximately 3dB additional attenuation at 1GHz.

Cost-Benefit Analysis

Black FR4 PCB typically costs 15-25% more than standard green:

Added Costs:

- Raw material: +$0.15-0.25/ft²

- Extended inspection time: +20% labor

- Lower yield rates: 2-3% reduction

- Specialized tooling for multilayer FR4 PCB

Value Propositions:

- Premium product positioning

- Enhanced thermal management

- Reduced optical interference

- Improved aesthetic appeal

ROI becomes positive at volumes >1000 units for consumer products where premium perception drives higher margins.

Design Guidelines for Black FR4 PCB

Silkscreen Optimization: White silkscreen provides maximum contrast. Minimum text height: 0.8mm for reliable legibility. Consider yellow FR4 PCB for safety-critical markings that require ultra-high visibility.

Trace Visibility: Exposed copper appears brighter against black mask—useful for debugging but requires careful aesthetic planning. Consider white FR4 PCB for applications where trace visibility must be minimized.

Component Placement: Black PCBs make component identification harder during assembly. Comprehensive silkscreen labeling and assembly drawings become critical.

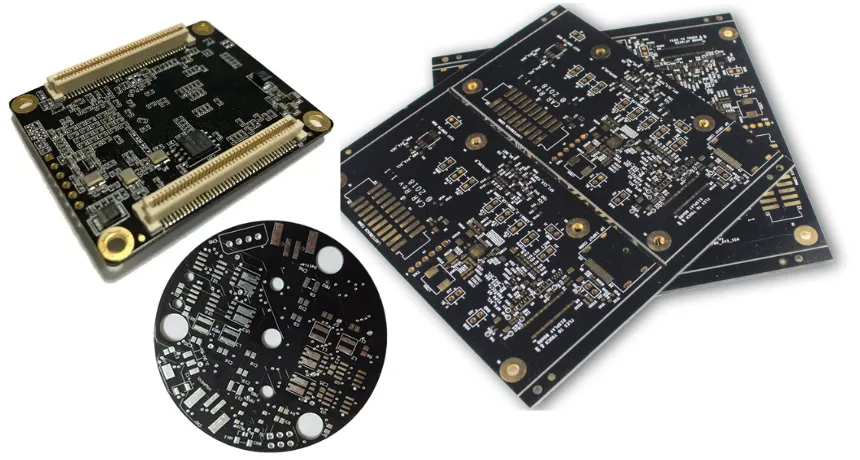

HILPCB Black FR4 Capabilities

- Matte and glossy finish options

- 10-30μm thickness control

- Support for single layer FR4 PCB through complex multilayer designs

- HDI and embedded component compatibility

- Selective black/green solder mask for cost optimization

Partner with HILPCB for black FR4 PCB manufacturing that balances aesthetics, performance, and cost. Our premium FR4 PCB processes ensure your high-end products meet both technical and visual requirements.