Blue FR4 PCB offers a distinctive combination of performance, inspection clarity, and professional appearance. While green remains the global standard, blue solder mask PCBs are increasingly chosen for medical electronics, industrial automation, and high-end branded products, where visibility and precision matter.

At HILPCB, we produce all major PCB technologies — from FR4 PCB and multilayer PCB to rigid-flex PCB and high-speed PCB. Our blue solder mask manufacturing combines advanced process control with strict quality assurance to ensure consistent appearance, adhesion, and performance across every batch.

When Blue FR4 Delivers the Best Technical and Visual Performance

Choosing blue FR4 is not only about aesthetics — it’s a decision based on inspection efficiency, process traceability, and brand identity. In production environments that demand high reliability, blue solder mask offers several functional advantages.

Clear Contrast for Optical Inspection

- Enhanced visibility for AOI systems: The blue background provides excellent contrast against gold (ENIG) pads and white silkscreen.

- Improved rework accuracy: Operators can easily identify solder joints, via barrels, and copper edges during manual inspection.

- Visual traceability: Ideal for factories implementing color-coded board identification by product line or customer.

This combination of professional appearance and process visibility makes blue FR4 particularly suitable for complex boards such as HDI PCB and high-frequency PCB.

Industry Applications: Medical and Industrial Electronics

Medical Device Applications

Medical electronics often require PCBs that look clean, reliable, and easily inspectable. Blue FR4 PCBs project a sterile, professional visual tone that complements medical-grade design. The color contrast helps technicians verify cleanliness and surface integrity quickly — important in environments where contamination control and visual quality assurance are critical.

Additionally, hospitals and OEMs often use blue solder mask to distinguish medical-grade hardware from consumer variants, simplifying compliance with FDA and ISO 13485 documentation.

Industrial Control and Automation

For industrial controllers, PLCs, and monitoring systems, blue FR4 PCBs convey service-grade quality while improving inspection and maintenance workflows. Maintenance teams can identify boards instantly by color, while the higher contrast between traces and silkscreen helps detect faults during both AOI and manual rework. Many brands also choose blue PCBs for corporate differentiation or as part of their industrial design language.

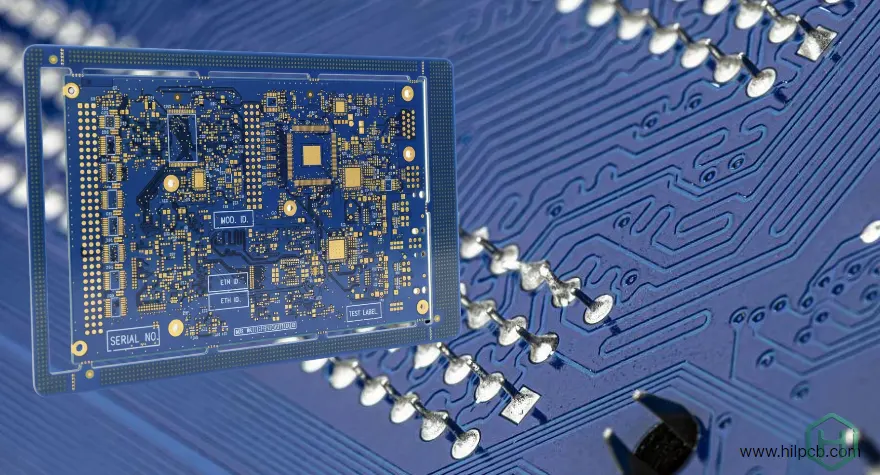

Manufacturing Specifications and Quality Control (Core Focus)

Producing blue FR4 PCBs demands tighter process management than standard green boards due to the optical density of pigments, adhesion chemistry, and exposure behavior. At HILPCB, our process is fine-tuned for accuracy, stability, and consistency.

1. Solder Mask Preparation and Coating

Blue solder masks use copper-phthalocyanine pigments suspended in epoxy resin. These pigments provide vivid coloration but increase UV absorption, requiring careful viscosity and coating control.

- Surface preparation: Micro-etching removes oxide film and ensures perfect adhesion on single-double-layer PCB copper surfaces.

- Coating method: Dual-pass curtain or spray coating ensures even 18–25 µm thickness across the panel.

- Pre-dry cycle: Controlled pre-bake at 80 °C prevents solvent entrapment and improves curing consistency.

Uniform coating thickness directly influences solder joint definition and long-term insulation resistance.

2. Exposure and Imaging Accuracy

Blue pigments absorb more UV light than green, so exposure energy must be increased by 10–20 %. We maintain strict exposure calibration at 350–400 mJ/cm² to achieve sharp imaging and prevent under- or over-cure. Fine-line accuracy is verified with optical inspection at 40× magnification to confirm solder mask alignment on dense pitch BGAs.

Our imaging systems support automatic compensation for mask edge gain, ensuring copper pad clearance within ±20 µm.

3. Development, Curing, and Adhesion Testing

During development, temperature and timing control are critical. Panels are processed at 30 °C for 50–60 seconds to remove unexposed material without damaging fine traces. Final curing occurs through a two-stage thermal cycle — 90 °C pre-bake followed by 150 °C final bake — achieving hardness ≥ 5H and adhesion ≥ 1.4 N/mm (per IPC-SM-840).

Adhesion is then verified using tape-pull and solvent-resistance testing. These parameters guarantee long-term stability even under SMT assembly reflow and cleaning operations.

4. Color Consistency and Optical Stability

One of the defining quality indicators for blue FR4 PCBs is color uniformity.

Pigment concentration and curing temperature directly influence hue and gloss. HILPCB implements SPC monitoring across batches to control ΔE color difference within ±3 units.

- Target coordinates: L* = 35 ± 2, a* = –5 ± 2, b* = –25 ± 3

- Gloss measurement: 30–50 GU @ 60° angle

- UV resistance: > 85 % color retention after 500 hours exposure

Our in-line colorimetry inspection guarantees consistent appearance for medical and branded electronic assemblies.

Cost Analysis and Alternative PCB Colors

Blue FR4 PCBs generally cost 8–15 % more than standard green due to pigment complexity and lower production volume. However, the enhanced inspection visibility, color coding, and branding value often outweigh the additional cost for professional applications.

For different design priorities:

- Heat management: Metal-core PCB provides superior thermal dissipation.

- Signal integrity: High-Tg PCB supports better mechanical and thermal stability.

- Light reflection: White mask options offer optimal brightness for LEDs.

- Halogen-free compliance: Halogen-free PCB meets RoHS and eco-regulations.

Design Optimization and Quality Assurance for Blue FR4 PCB

Achieving reliable performance and consistent appearance in blue FR4 PCB design requires careful coordination between layout engineering and manufacturing quality control. From solder mask clearance to surface inspection, every design decision influences long-term durability, readability, and overall production yield.

Design and Layout Optimization

When designing with a blue solder mask, specific layout adjustments help ensure both functional clarity and visual precision:

- Silkscreen contrast: White silkscreen offers the best readability on blue backgrounds, while yellow can be used for caution markings or special indicators.

- LED color accuracy: Compensate for the slight color temperature shift caused by the blue surface by fine-tuning LED bin selection or lens diffusion.

- Solder mask clearance: Maintain a minimum 0.15 mm relief between mask and copper to prevent overexposure or bridging during photoimaging.

- Visual consistency: Apply blue solder mask selectively for medical, industrial, or high-end product lines to reinforce brand identity and product differentiation.

Before production, conducting DFM validation using our online Gerber viewer allows engineers to check solder mask alignment, copper spacing, and via clearance — ensuring that the PCB layout is optimized for fabrication accuracy.

Quality Standards and Reliability Verification

At HILPCB, every blue FR4 PCB undergoes comprehensive reliability and visual inspection to guarantee consistent performance and appearance across production batches.

- Dielectric strength: >1200 V/mil

- Surface insulation resistance: >10¹¹ Ω

- Mask hardness: ≥5H pencil hardness

- Thermal cycling test: –40 °C to +125 °C for 500 cycles

- Adhesion and solvent resistance: Verified through cross-hatch and wipe testing

These combined design best practices and inspection protocols ensure that every blue FR4 PCB from HILPCB meets IPC Class 3 or automotive-grade reliability standards, delivering both visual excellence and electrical integrity.

Conclusion — Reliable Performance and Visual Consistency

Blue FR4 PCBs combine the electrical stability of traditional FR4 with a clean, professional appearance favored in visible assemblies, development kits, and branded electronics. The blue solder mask not only enhances visual identification during inspection and rework but also maintains the same mechanical strength, insulation resistance, and heat tolerance expected from high-quality FR4 materials.

At HILPCB, every Blue FR4 PCB is produced under tightly controlled solder mask coating and curing processes to ensure even color tone, smooth surface finish, and consistent thickness across batches. Whether your goal is brand differentiation or enhanced visual traceability, our manufacturing expertise guarantees dependable quality, stable yields, and smooth assembly performance from prototype through mass production.

Partner with HILPCB for Your Blue FR4 PCB Projects

Choosing HILPCB means more than getting a good-looking circuit board — it means working with a partner who understands both design aesthetics and manufacturing precision. Our integrated fabrication and assembly services ensure that your blue FR4 boards not only look professional but also meet the electrical and mechanical standards your application demands.

With rigorous inspection, full traceability, and responsive engineering support, we help customers achieve consistent results and long-term reliability across every build. Contact our team to discuss your next Blue FR4 PCB project and experience how precision, reliability, and color consistency come together in every board we manufacture.