As electronic products evolve toward higher power, speed, and integration density, buried via PCB technology has become indispensable for advanced multilayer designs.

From high-speed computing systems and automotive control units to power converters and satellite electronics, buried vias make it possible to achieve compact routing, strong thermal performance, and exceptional long-term reliability.

At HILPCB, we combine precise lamination, laser drilling, and copper filling processes to manufacture buried via PCBs that meet the stringent mechanical, electrical, and thermal requirements of today’s high-performance industries.

Understanding Buried Via PCB Technology

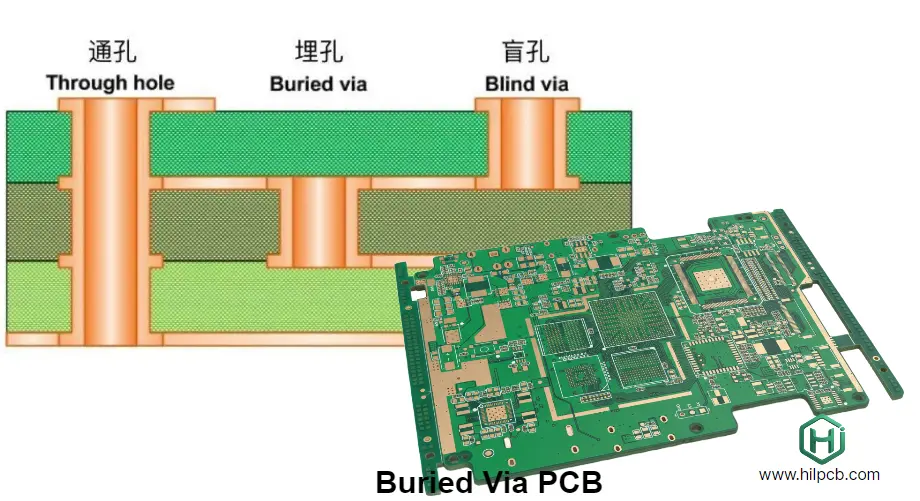

A buried via connects two or more internal layers of a multilayer PCB without reaching the external surfaces. This structure increases routing flexibility while freeing up outer layers for surface components, creating dense interconnects essential for HDI PCB and high-reliability multilayer board applications.

Key Advantages of Buried Via PCBs:

- Higher circuit density without expanding board dimensions

- Isolation of power and signal layers for improved EMI performance

- Shorter interconnect lengths reducing signal delay and loss

- Enhanced mechanical rigidity through balanced internal stacking

- Optimized heat dissipation paths for power-intensive designs

Paired with blind vias and through vias, buried vias allow designers to create complex layer architectures — enabling up to 30+ layers in advanced computing and industrial systems.

Key Manufacturing Processes at HILPCB

High-reliability buried via PCBs require precise process integration and material control. At HILPCB, every stage of production is engineered for consistency and repeatability.

1. Engineering and DFM Review

Each project starts with a detailed Design for Manufacturability (DFM) review.

Our engineers assess:

- Via aspect ratios and minimum annular rings

- Layer stack-up and dielectric balance

- Thermal expansion coefficients for material compatibility

- Signal integrity and impedance modeling for high-speed circuits

We use simulation tools and cross-section data from past builds to recommend layout optimizations that improve manufacturability and reduce lamination stress.

2. Material and Lamination Control

Material choice directly impacts buried via stability.

HILPCB uses high-reliability substrates including:

- High-Tg FR-4 (Tg ≥170 °C) for automotive and industrial applications

- Polyimide laminates for aerospace and extended thermal cycling

- Heavy copper PCB layers for high-current density

- Halogen-free PCB materials compliant with RoHS and REACH

Sequential lamination is tightly controlled to maintain ±75 μm registration accuracy, ensuring proper via alignment and dimensional stability in complex builds.

3. Laser Drilling and Copper Filling

Buried vias are created before final lamination using mechanical or laser drilling depending on via depth and dielectric type. After drilling:

- Plasma desmear removes resin residue

- Electroless copper seeding ensures adhesion

- Pulse electroplating fills vias with copper for void-free interconnects

- Planarization creates a smooth surface for subsequent lamination stages

Our process supports stacked buried vias and copper-filled structures compatible with via-in-pad assembly.

4. Quality Assurance and Reliability Testing

All buried via PCBs are validated through automotive-grade inspection and testing:

- 100% electrical continuity and isolation tests

- Cross-section microanalysis verifying copper wall integrity (≥25 μm)

- X-ray inspection of via registration and fill quality

- Thermal cycling (−40 °C to +150 °C, 1,000+ cycles)

- Vibration and shock testing per IPC-6012 Class 3A

This ensures each buried via structure maintains electrical stability and mechanical integrity throughout its service life.

Cross-Industry Applications of Buried Via PCB

Buried via PCBs are now fundamental to nearly every advanced electronic sector, where performance, miniaturization, and long-term reliability are critical. By enabling interconnections between internal layers without consuming surface space, buried vias deliver higher circuit density, improved heat management, and superior electrical performance — essential for modern automotive, aerospace, data, and energy systems.

Automotive and Electric Vehicle Systems

Automotive electronics operate in one of the harshest environments of any industry. Buried via PCB designs enable compact multilayer control boards that handle power, sensing, and communication within limited space while maintaining vibration and thermal stability.

- Applied in ADAS radar, battery management systems (BMS), inverters, and motor control units (MCU)

- Buried vias reinforce grounding continuity and reduce EMI between digital and analog layers

- Integration with High-Tg PCB and heavy copper PCB enhances current capacity and heat dissipation

- Copper-filled buried vias distribute heat evenly, extending lifetime under −40 °C to +150 °C thermal cycling

These structures allow automotive engineers to combine reliability with the routing density required by next-generation EV and intelligent mobility systems.

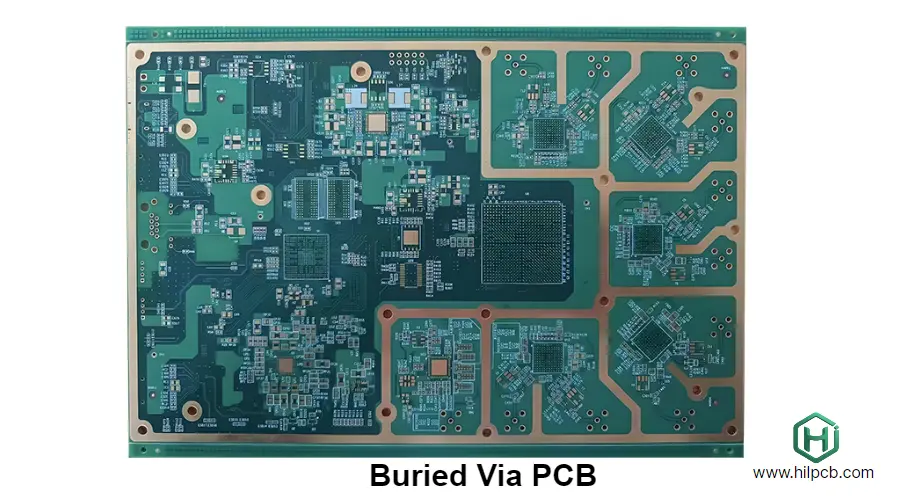

High-Performance Computing and Data Servers

In servers, GPUs, and AI accelerators, PCB density directly determines system bandwidth and efficiency. Buried via PCBs provide uninterrupted routing channels within 20–40 layer HDI PCB architectures, minimizing crosstalk and signal loss.

- Used in CPU/GPU motherboards, switch fabrics, and AI accelerator boards

- Buried vias reduce stub effects and enable precise impedance control for PCIe Gen5/6, DDR5, and CXL links

- Controlled dielectric layers ensure synchronization across multi-chip modules

- Enhanced copper balance prevents warpage and mechanical strain in large-format server boards

This makes buried via PCBs indispensable for high-speed computing and data infrastructure applications.

Aerospace, Defense, and Satellite Systems

Aerospace and defense electronics demand lightweight, radiation-tolerant, and mechanically stable designs. Buried vias deliver compact, layered interconnects that maintain reliability under vibration, thermal shock, and altitude extremes.

- Found in avionics, satellite transceivers, navigation, and telemetry modules

- Polyimide-based buried via PCBs resist outgassing and withstand >250 °C peak reflow

- Copper-filled vias provide structural reinforcement against launch vibration

- Multi-ground buried vias reduce RF interference in high-frequency radar and communication arrays

By combining structural integrity and weight reduction, buried via PCBs help aerospace engineers meet mission-critical reliability standards.

Renewable Energy and Power Conversion

Power conversion systems in renewable and industrial energy sectors depend on buried via PCBs for high-current routing and thermal stability. They are vital in solar inverters, energy storage systems, and motor drives, where power density continues to increase.

- High-thermal PCB and metal core PCB layers integrated with buried vias spread heat effectively

- Stacked buried vias reduce voltage drops and distribute load currents evenly

- Hybrid stack-ups combine FR-4 and polyimide to balance insulation and conductivity

- Proven to maintain performance during repetitive high-load switching cycles

This ensures long-term operational stability and lower energy loss in demanding power systems.

5G, RF, and Communication Equipment

5G networks and RF communication devices rely on buried via PCBs for high-frequency performance and compact packaging. Precise dielectric control and low-loss interconnects are essential for consistent transmission.

- Used in base stations, microwave amplifiers, antenna arrays, and network processors

- Buried vias enable multilayer shielding between high-frequency and power circuits

- Rogers PCB materials reduce signal attenuation and dielectric loss

- Optimized ground via networks maintain impedance uniformity up to 77 GHz

With their ability to minimize interference and enhance signal integrity, buried via PCBs are key to enabling next-generation wireless infrastructure.

Consumer and Industrial Electronics

In advanced consumer and industrial products — from medical imaging systems to robotics and IoT controllers — buried via PCBs provide balance between compactness and reliability.

- Support high I/O density and multilayer routing within compact form factors

- Improve mechanical rigidity and thermal endurance for continuous operation

- Enable cost-effective miniaturization in wearables, automation, and embedded devices

Their combination of precision and versatility allows engineers to design thinner, lighter, and more reliable systems across every major electronics segment.Design and Reliability Guidelines

HILPCB follows strict design parameters to guarantee buried via durability and consistency:

- Aspect ratio ≤ 10:1 for robust plating

- Minimum copper wall thickness ≥ 25 μm

- Staggered stacking reduces z-axis stress during lamination

- Balanced layer thickness to minimize warpage

- Resin-filled and capped via options for improved structural strength

- Verified compliance with IPC-TM-650 and JEDEC JESD22 standards

Our engineering team provides pre-layout support to ensure electrical, mechanical, and thermal objectives are met before production begins.

Why Partner with HILPCB for Buried Via PCB Manufacturing

Choosing a PCB partner that understands buried via and blind via integration is essential for high-density, high-reliability designs. At HILPCB, we combine decades of multilayer PCB manufacturing experience with advanced automation and material expertise to deliver boards that meet the highest electrical, mechanical, and thermal reliability standards.

Our production capabilities cover the entire HDI stack — from buried via PCB structures used in dense multilayer routing to blind via PCB configurations for high-speed signal and surface interconnections. By optimizing sequential lamination, copper filling, and via alignment, we ensure every board achieves consistent impedance, low resistance, and superior yield.

With end-to-end services spanning DFM consultation, material engineering, laser drilling, and automotive-grade validation, HILPCB supports customers across automotive, aerospace, communication, computing, and energy sectors. We help engineers achieve compact form factors, higher signal integrity, and long-term reliability — from prototype through full-scale production.

When performance, density, and dependability matter, HILPCB is your trusted partner for next-generation buried and blind via PCB manufacturing.