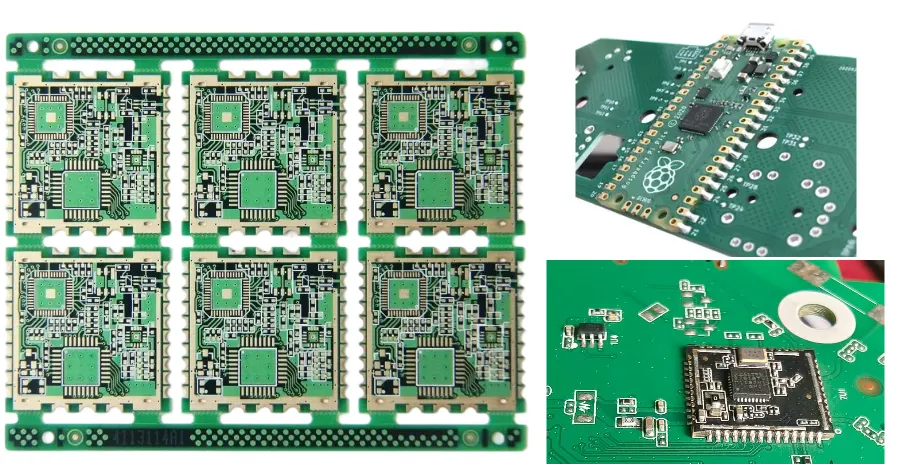

Castellated PCBs are a unique and critical feature for miniaturized electronics that require both compactness and high-performance interconnects. These specialized designs feature semi-circular or semi-rectangular pads that are exposed on the edge of the PCB to facilitate easier soldering onto another board or substrate, often used in embedded system designs, wireless modules, or sensors.

At Highleap PCB Factory, we are not limited to any single PCB type—we manufacture a wide range of PCB solutions, with a particular focus on complex and specialized designs. Our expertise spans from Castellated PCBs to high-density, high-frequency, and low-profile circuit boards for diverse applications. Our capabilities allow us to produce precision Castellated PCBs using advanced processes, materials, and testing techniques for a wide range of industries, including aerospace, telecommunications, IoT, and medical devices.

Key Features and Benefits of Castellated PCBs

Castellated PCBs are designed with specific features to enhance connectivity and integration. Key attributes include:

- Edge-mounted solder pads: The semi-circle or semi-rectangular pads on the edge of the PCB allow for direct soldering to another PCB, making them ideal for modular or compact systems.

- High-density interconnects (HDI): The use of HDI techniques ensures smaller, more efficient interconnects while maintaining signal integrity, which is critical for high-speed applications.

- Space-saving design: Castellated PCBs minimize the footprint of components, making them ideal for compact, space-constrained applications such as wireless communication devices and medical equipment.

- Seamless integration: Their design allows easy and reliable mounting to other substrates or PCBs, which can be used in flexible designs or advanced packaging applications.

At Highleap PCB Factory, we offer customized solutions for Castellated PCBs that meet specific design requirements and ensure optimal performance in every application.

Applications for Castellated PCBs

Castellated PCBs are ideal for applications where space is at a premium and high-density interconnects are essential. Some common applications include:

- Wireless Modules: Castellated pads are commonly used in wireless communication boards, such as Bluetooth or Wi-Fi modules, where compactness and efficient connections are necessary.

- Aerospace and Defense: High-reliability designs in the aerospace sector demand precision PCB manufacturing, including Castellated PCBs, to ensure strong connectivity in space-constrained, high-performance systems.

- Medical Devices: Miniaturized devices such as sensors, pacemakers, and diagnostic instruments often utilize Castellated PCBs to ensure high integration and reliability.

- Embedded Systems: In embedded applications, where multiple boards are connected in a compact environment, Castellated PCBs provide a clean, reliable interconnect solution.

Castellated PCBs play a critical role in enabling miniaturization and enhancing the performance of these high-density, low-profile devices.

Highleap PCB Factory’s Advanced Process for Castellated PCBs

Highleap PCB Factory employs advanced PCB fabrication techniques and precision engineering to create high-quality Castellated PCBs. Our process includes:

- Advanced PCB stack-up designs: Tailored stack-ups that include special materials and impedance control to meet specific performance and reliability requirements.

- Laser-etched and precision drilling: To achieve the exact geometry needed for Castellated pads, our facility uses high-precision laser-etching and drilling processes.

- Impedance control: Critical for high-speed and RF applications, our Impedance Calculator ensures that the signal integrity is preserved across every interconnect.

- Quality Assurance: From design verification with Gerber Viewer to end-to-end electrical testing, Highleap PCB Factory guarantees that each Castellated PCB meets the highest standards of quality and reliability.

Why Choose Highleap PCB Factory for Castellated PCBs?

Highleap PCB Factory provides a comprehensive range of benefits when it comes to Castellated PCB manufacturing:

- Customization: We work closely with clients to understand their design needs, offering custom stack-ups and design solutions that meet the unique challenges of each project.

- Fast Turnaround: Our optimized production lines and experience with both small and large production runs allow us to deliver high-quality Castellated PCBs on time.

- High-reliability: With certifications for IPC Class 2/3, we ensure that every Castellated PCB meets the most demanding standards for performance and durability.

- Cost-effective solutions: Whether you need a small batch for prototyping or large-scale production, Highleap PCB Factory offers competitive pricing while maintaining high-quality standards.

We offer a full range of PCB products, including high-speed PCBs, high-frequency PCBs, and HDI PCBs, ensuring we meet the specific requirements of every project.