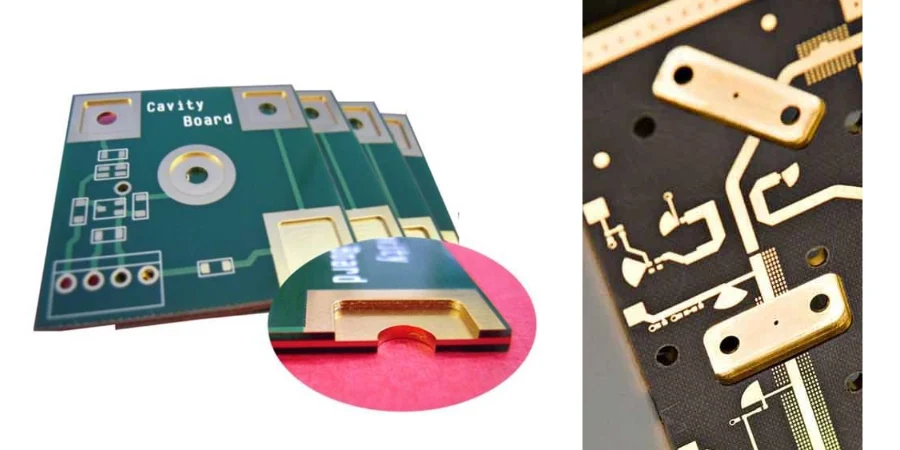

Cavity PCBs are essential when components need to sit partially or fully recessed within the circuit board to reduce height, optimize RF behavior, or improve thermal performance. At Highleap PCB Factory, we specialize in fabricating cavity PCBs with precision depth control, material consistency, and high-reliability structure.

From RF transceiver modules to MEMS sensors and chip-on-board (CoB) packages, our cavity solutions reduce signal path length, eliminate interposers, and enable compact product architecture. Whether it’s a single or multilayer cavity structure, we manufacture to your spec—no shortcuts.

Key Capabilities in Cavity PCB Fabrication

At Highleap PCB Factory, cavity structures are integrated during lamination or post-drilling with tight Z-axis control. We support:

- Multi-depth cavity routing with ±0.05 mm depth tolerance

- Cavity exposure down to copper or prepreg layers

- Hybrid stackups combining FR4 PCB, ceramic PCB, and high-frequency PCB

- Recessed zones under QFNs, ASICs, bare-die, or coils

- EMI shielding with cavity metalization or copper-in-fill

With in-house 3D PCB Viewer, you can validate cavity profiles and adjacent layer clearances visually before fabrication.

Where Cavity PCBs Make the Difference

Cavity PCB technology plays a pivotal role in space-constrained, high-frequency, or thermally sensitive designs. Below is a look at application scenarios where embedded cavities are essential—not optional.

| Application Area | Functional Advantage |

|---|---|

| RF Modules | Accommodate power amplifiers or filters closer to the plane |

| Sensor Integration | Reduce Z-height in pressure, motion, or optical sensing |

| Semiconductor Test Boards | Enable socket/cavity for IC substrate PCB testing |

| Coaxial & Antenna Interfacing | Support cavity-to-grounded-RF trace transitions |

| Flip-Chip Assembly | Support underfill and ground-via termination for HDI PCB |

Additionally, we engineer cavity boards for wearable, telecom, and optical communication devices—often combining them with [rigid-flex PCB] to meet both form and function requirements.

Tailored Material Choices for Precision Cavities

When it comes to cavity structures, selecting the wrong base material can jeopardize depth accuracy, thermal management, or RF consistency. At Highleap PCB Factory, we combine material science with precision milling to ensure every recess is structurally sound and dimensionally stable.

Some of our go-to stackup enhancements include:

- High-Tg PCB for heat-resistant CoB zones that endure multiple reflow cycles

- Teflon PCB in low-loss RF designs that embed filters or couplers inside cavities

- Advanced ceramic blends for cavity PCBs used in radar or satellite payloads

- Copper-infilled metal-core PCB for heat-sink-integrated cavity pockets

These material combinations are validated using our in-house Gerber Viewer, which helps customers inspect cavity shapes, copper reference planes, and adjacent trace spacing before the board moves to CAM.

For cavity PCBs, not all laminates behave equally under controlled-depth milling. Highleap PCB Factory supports:

- Thermally stable [high-Tg PCB](High Tg Pcb) for CoB and BGA-cavity zones

- [Teflon PCB](Teflon Pcb) for minimal Df in RF cavity modules

- Low CTE ceramics for chip packaging zones with thermal expansion limits

- Metal-core base layers for cavity designs requiring heat spreaders

Why Choose Highleap PCB Factory for Cavity Boards

Highleap PCB Factory is trusted globally for precision manufacturing and multilayer cavity designs. Our edge comes from:

- 3D-controlled depth routing and hybrid stackup engineering

- Full CAM and DFM support with built-in impedance control

- ISO-certified production with IPC Class 2/3 options

- Fast global shipping and after-sales support

We are not limited to cavity PCBs—we build [multilayer PCB](Multilayer Pcb), [flex PCB](Flex Pcb), and advanced high-speed PCB structures every day. Our strengths in high-mix, low-volume manufacturing make us ideal for R&D and commercial scale-up alike.