Highleap PCB Factory (HILPCB) specializes in manufacturing high-performance ceramic circuit boards that excel in extreme thermal, electrical, and mechanical environments. Our advanced ceramic PCB capabilities deliver superior thermal management, exceptional electrical insulation, and unmatched reliability for power electronics, LED lighting, RF/microwave systems, and automotive applications where traditional PCB materials fall short.

Advanced Ceramic Materials and Thermal Performance

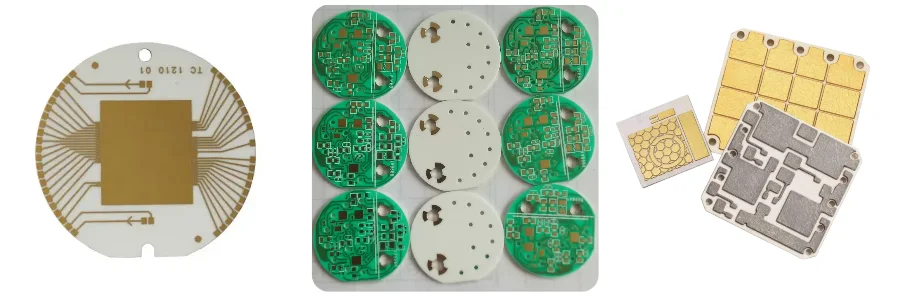

Ceramic circuit boards utilize inorganic, non-metallic substrates that fundamentally outperform organic materials in thermal conductivity, dimensional stability, and high-temperature operation. Our ceramic PCB manufacturing encompasses three primary material systems:

Alumina (Al2O3) Substrates

- 96% Al2O3: Standard ceramic with 24-28 W/m·K thermal conductivity

- 99.6% Al2O3: High-purity option with superior electrical properties

- Thermal expansion coefficient: 6.5-7.5 ppm/K matching silicon devices

- Maximum operating temperature: 1500°C in inert atmosphere

Aluminum Nitride (AlN) Solutions

- Exceptional thermal conductivity: 170-230 W/m·K

- Low dielectric constant: 8.8 at 1 MHz

- Thermal expansion: 4.5 ppm/K for optimal semiconductor matching

- Ideal for high-power RF amplifiers and laser diodes

Specialized Ceramic Options

- Beryllium Oxide (BeO): 280 W/m·K thermal conductivity with handling precautions

- Silicon Nitride (Si3N4): Superior fracture toughness for thermal cycling

- LTCC (Low Temperature Co-fired Ceramic): Multilayer 3D integration capability

The inherent properties of ceramic substrates - zero moisture absorption, chemical inertness, and exceptional dimensional stability - make them irreplaceable in applications where FR-4 PCB or metal core PCB materials cannot meet performance requirements.

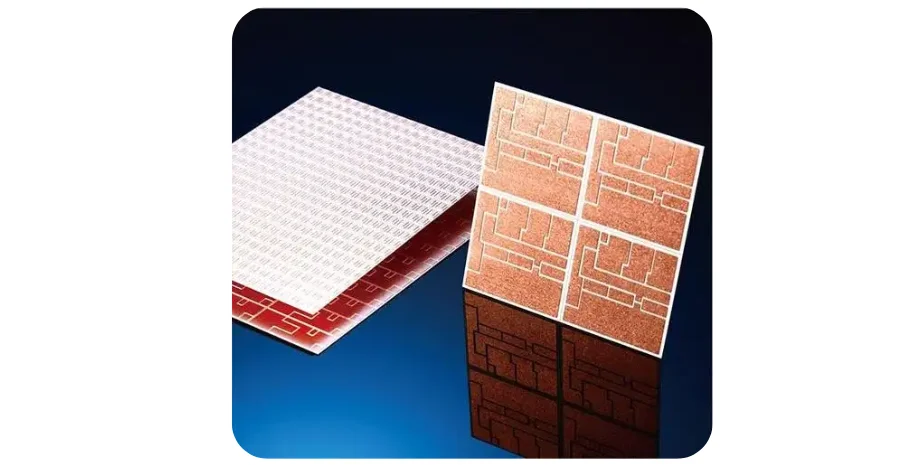

Metallization Technologies for Ceramic Circuit Boards

Creating reliable conductor patterns on ceramic substrates requires specialized metallization processes fundamentally different from traditional PCB manufacturing:

Direct Bonded Copper (DBC)

- Copper foils from 127μm to 400μm thickness

- High-temperature bonding at 1065°C forming Cu-O eutectic

- Current carrying capacity exceeding 100A per trace

- Thermal cycling reliability: -55°C to +150°C for 1000+ cycles

Thick Film Technology

- Screen-printed conductor pastes (Ag, Au, Cu, AgPd)

- Fine line capability: 75μm traces with 75μm spacing

- Multi-layer capability with via interconnects

- Embedded resistors and capacitors for integrated passives

Thin Film Processing

- Sputtered or evaporated metallization for precision

- Line/space capability down to 10μm

- Ideal for microwave and high-frequency applications

- Compatible with wire bonding and flip-chip assembly

Our ceramic PCB facility maintains Class 1000 cleanroom environments for thin film processing, ensuring contamination-free metallization critical for high-reliability applications.

Manufacturing Excellence for Ceramic PCB Production

HILPCB's ceramic circuit board manufacturing combines advanced equipment with rigorous process controls:

Laser Processing Systems

- CO2 and UV laser drilling for via formation

- Precision singulation without mechanical stress

- Scribing for controlled fracture separation

- Minimum via diameter: 50μm with ±10μm tolerance

Quality Control Infrastructure

- Automated optical inspection with 0.5μm resolution

- X-ray inspection for internal defects

- Coordinate measuring machines for dimensional verification

- Thermal impedance testing for heat dissipation validation

Production Capabilities

- Panel sizes up to 200mm x 200mm

- Thickness range: 0.25mm to 3.0mm

- Single-sided, double-sided, and multilayer configurations

- Monthly capacity: 50,000+ ceramic substrates

Quick-turn prototyping delivers ceramic PCBs in 7-10 days for standard designs, with volume production scaling seamlessly through automated handling systems designed for brittle substrate materials.

Thermal Management Solutions Using Ceramic Substrates

Ceramic circuit boards offer outstanding thermal conductivity and stability, making them ideal for applications where heat dissipation is critical to system performance and longevity. At HILPCB, we specialize in ceramic PCB solutions tailored to high-heat environments across lighting and power systems.

In high-power LED applications, our ceramic substrates enable industry-leading thermal performance. We achieve junction-to-board thermal resistance as low as 0.5 °C/W, support direct die attachment that eliminates the need for intermediate thermal interface materials, and ensure over 50,000 hours of reliable operation at junction temperatures of 150 °C. Our boards also support phosphor deposition for integrated white light generation.

For power electronics integration, we support advanced packaging needs including IGBT modules with integrated gate drivers, and high-efficiency SiC and GaN power devices. Our ceramic PCBs enable direct liquid cooling through metallized microchannel designs and deliver thermal spreading capabilities up to 10 times greater than standard FR-4 materials.

To further enhance performance, we provide thermal simulation services utilizing finite element analysis (FEA). These simulations guide design optimization of copper distribution, via placement, and component layout to maximize heat dissipation and ensure thermal reliability under demanding operating conditions.

Assembly Services for Ceramic Circuit Boards

Beyond substrate manufacturing, HILPCB provides specialized SMT assembly services adapted for ceramic materials:

Process Adaptations

- Preheating profiles preventing thermal shock

- Specialized fixtures accommodating ceramic brittleness

- Lead-free soldering with controlled cooling rates

- Wire bonding using gold or aluminum wires

Component Attachment Methods

- Conductive epoxy for stress-sensitive components

- Eutectic die attachment for maximum thermal performance

- Flip-chip assembly with underfill dispensing

- Silver sintering for extreme temperature operation

Our turnkey assembly services include component sourcing, programming, and functional testing, delivering complete ceramic circuit board solutions ready for system integration.

Global Delivery and Customer Support Excellence

At HILPCB, we simplify the procurement of ceramic circuit boards through a full suite of professional support services. Our engineering partnership begins with a complimentary DFM (Design for Manufacturability) review tailored to the unique challenges of ceramic substrates. We provide expert advice on material selection, conduct thermal simulations and mechanical stress analysis, and recommend cost-effective design modifications to optimize performance and manufacturability.

To ensure a seamless experience, our logistics and payment solutions include global shipping with packaging designed specifically for ceramic board protection. We use shock-absorbing materials to safeguard your products during transit. Customers can choose from multiple payment options such as PayPal and wire transfer, and qualified clients may access NET terms for added flexibility.

Our quality assurance framework guarantees consistent excellence. Every board undergoes 100% electrical testing to meet customer specifications. We provide dimensional inspection reports backed by statistical analysis, issue material certificates verifying composition and properties, and maintain traceability through unique serialization. Beyond delivery, our support continues with guidance for assembly, troubleshooting, and iterative design improvements based on real-world testing feedback

FAQ

What are the main advantages of ceramic circuit boards over traditional PCBs?

Ceramic circuit boards offer 10-100x better thermal conductivity than FR-4, enabling superior heat dissipation for high-power applications. They maintain dimensional stability at extreme temperatures, exhibit zero moisture absorption, and provide excellent electrical insulation even at high frequencies. These properties make ceramics essential for power electronics, RF systems, and LED applications.

How do ceramic PCB costs compare to standard circuit boards?

Ceramic substrates typically cost 3-10x more than equivalent FR-4 boards due to specialized materials and processing. However, the total system cost often favors ceramics through elimination of heatsinks, improved reliability, and extended operating life. We provide detailed cost analysis comparing ceramic solutions with traditional approaches for your specific application.

Can ceramic circuit boards be manufactured in multilayer configurations?

Yes, we manufacture multilayer ceramic PCBs using LTCC (Low Temperature Co-fired Ceramic) technology supporting up to 20 layers. This enables complex 3D circuit integration with embedded passives, cavities, and channels. Standard alumina and AlN substrates are typically limited to single or double-sided configurations with thick film multilayer capabilities.

What design rules apply to ceramic circuit board layouts?

Ceramic PCBs require modified design rules including: minimum trace width of 100μm for thick film (10μm for thin film), via diameters starting at 100μm, and keepout zones near board edges to prevent chipping. We provide comprehensive design guidelines specific to your chosen ceramic material and metallization technology.

How quickly can you deliver ceramic circuit board prototypes?

Standard ceramic PCB prototypes ship in 7-10 business days for single/double-sided designs. Complex multilayer LTCC or custom metallization may require 15-20 days. We maintain inventory of common ceramic materials to minimize lead times and offer expedited services for urgent requirements.

What certifications do you hold for ceramic PCB manufacturing?

HILPCB maintains ISO 9001:2015 quality certification, IATF 16949 for automotive applications, and AS9100D for aerospace. Our ceramic processes comply with IPC standards adapted for ceramic substrates. We provide material traceability, RoHS compliance documentation, and custom testing certifications as required.