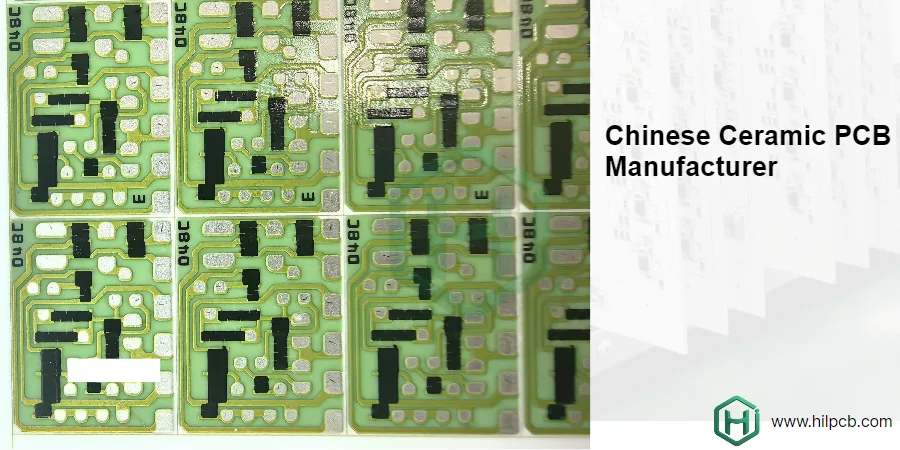

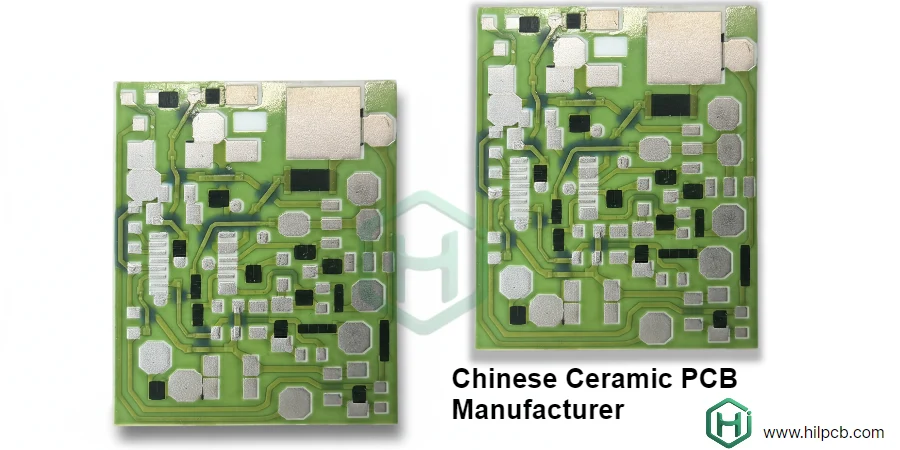

As a leading ceramic PCB manufacturer, HILPCB Factory combines precision processing, material science, and full electronic integration to deliver high-performance ceramic circuit boards for global industries. From prototype fabrication to mass production and assembly, we provide end-to-end solutions for power electronics, aerospace, RF/microwave, and medical applications requiring exceptional heat dissipation and reliability.

Our vertically integrated facilities support a full range of materials — including Al₂O₃, AlN, Si₃N₄, Rogers, and FR4 — enabling hybrid manufacturing across multiple PCB technologies.

What Defines a Reliable Ceramic PCB Manufacturer

A reliable ceramic PCB manufacturer must combine material expertise, process precision, and quality assurance across every fabrication stage. Ceramic boards differ fundamentally from organic laminates — their brittleness, thermal conductivity, and surface energy require specialized handling and processing.

HILPCB meets these challenges through:

- Comprehensive Technology Portfolio: DBC, DPC, and HTCC PCB production lines under one roof.

- Material Versatility: Compatibility with aluminum oxide, aluminum nitride, silicon nitride, and hybrid stackups.

- High Precision Standards: Tight tolerances for thickness, flatness, and trace alignment critical to Thin Film PCB and RF applications.

- Traceable Manufacturing: Full process documentation and lot-level traceability for medical and aerospace compliance.

These attributes define the foundation of quality ceramic PCB manufacturing trusted by engineers worldwide.

In-House Production Capabilities and Equipment

At HILPCB Factory, ceramic PCB manufacturing is performed entirely in-house, ensuring total process control and consistent reliability. Our facility integrates substrate preparation, metallization, drilling, plating, finishing, and assembly in a single streamlined workflow.

Core Fabrication Capabilities

Substrate Machining and Polishing

Ceramic blanks are ground and polished to achieve thickness uniformity within ±10 µm. Surface roughness below Ra 0.2 µm ensures strong metallization adhesion and stable dielectric performance.Advanced Metallization Lines

- DBC Process: Direct copper bonding at >1000°C for power modules and high-current circuits.

- DPC Process: Thin-film sputtering and electroplating for fine-line RF and LED designs.

- HTCC Process: Co-firing with tungsten or molybdenum for hermetic and high-temperature environments.

Each process is automatically monitored for adhesion, conductivity, and film thickness uniformity.

Laser Drilling and Patterning

Dual-wavelength laser systems achieve hole diameters as small as 50 µm with positional accuracy of ±5 µm. CO₂ and UV lasers handle both thick and thin ceramic layers without inducing microcracks.Precision Plating and Surface Finishing

Electroless and electrolytic copper systems provide uniform deposition. Surface finishes such as ENIG, ENEPIG, hard gold, or silver are applied for optimal solderability and bond strength during Ceramic PCB Assembly.Automated Dimensional Inspection

Non-contact optical metrology and 3D scanning ensure compliance with mechanical and electrical tolerances. Each panel undergoes cross-sectional analysis to verify via and plating integrity.

By maintaining complete in-house control, HILPCB minimizes lead time, enhances consistency, and ensures that every board meets or exceeds IPC and ISO performance standards.

Quality Control and Testing Processes

Every ceramic PCB manufactured by HILPCB is verified through rigorous electrical, thermal, and mechanical testing.

Testing Workflow Includes:

- Dielectric Breakdown and Insulation Resistance Testing for substrate integrity.

- Adhesion and Shear Strength Validation for copper-ceramic bonding.

- Thermal Shock and Cycling to simulate long-term operational reliability.

- X-ray and AOI Inspection for detecting hidden voids or microcracks.

- High-Frequency Impedance Measurement ensuring signal consistency for Ceramic PCB Fabrication and RF modules.

All processes conform to IPC-6018, MIL-PRF-31032, and AS9100 aerospace standards, ensuring reliability in critical applications.

Applications and Industry Coverage of Ceramic PCBs

Ceramic PCBs are essential in industries where thermal management, electrical insulation, and structural stability define system reliability. HILPCB supports customers across multiple sectors, offering custom solutions from prototypes to production-level assemblies.

Core Industry Applications

- Power Electronics: For IGBT modules, DC/DC converters, and EV inverters requiring high thermal conductivity.

- RF & Microwave Systems: Used in 5G base stations, radar transceivers, and satellite modules for low-loss, high-frequency performance.

- Aerospace & Defense: Hermetic and vibration-resistant ceramics ensure reliability in extreme environments.

- Medical Devices: High-purity ceramic boards support implantable and diagnostic systems with biocompatibility and long-term stability.

- Industrial & Energy Systems: Robust substrates for laser drivers, sensors, and high-power LED assemblies.

With hybrid manufacturing expertise, HILPCB can integrate ceramic, FR4, Rogers, and metal-core PCBs within a single device, simplifying multi-board product development.

Experience in Ceramic, HTCC, and Thin Film Technologies

With decades of experience in ceramic circuit design and fabrication, HILPCB offers expertise across multiple advanced technologies:

- Ceramic PCB Manufacturing: Al₂O₃, AlN, and Si₃N₄ substrates for power and thermal management.

- HTCC PCB and co-fired multilayer circuits for hermetic and high-temperature systems.

- Thin Film PCB fabrication using sputtered metals for microelectronic and sensor applications.

- Hybrid Integration: Combining ceramic with Rogers, metal-core, or FR4 layers to achieve optimal performance across mixed circuits.

This comprehensive capability enables our clients to consolidate multiple technologies under one manufacturing partner.

Why HILPCB Is a Trusted Ceramic PCB Manufacturer

Choosing HILPCB means working with a manufacturer that supports the entire electronics value chain — from raw substrate processing to final PCB assembly and box build integration.

Our Advantages:

- Complete One-Stop Service: Fabrication, assembly, and testing within a single quality-controlled system.

- Cross-Material Expertise: Ceramic, FR4, Rogers, and metal-core PCB production for multi-board systems.

- Engineering Support: DFM/DFA consultation for high-yield, cost-effective production.

- Certified Quality: ISO 9001, IATF 16949, and AS9100 certification for global industry compliance.

- Scalable Production: From quick-turn prototypes to full-scale manufacturing with global logistics support.

Whether you’re designing power modules, radar circuits, or medical sensors, HILPCB Factory provides the precision, consistency, and technical depth needed for next-generation electronics.

Learn more in our Ceramic PCB Manufacturing guide or explore our Ceramic PCB Product Page to discover how we can support your next project.