For electronics operating at the limits of power, temperature, and frequency, ceramic PCB manufacturing provides the foundation for ultimate reliability. At HILPCB, we are industry leaders in this specialized field. By mastering advanced processes like Direct Bonded Copper (DBC), Direct Plated Copper (DPC), and High-Temperature Co-fired Ceramic (HTCC), we produce high-performance substrates delivering unparalleled thermal management, dimensional stability, and long-term reliability where conventional FR-4 substrates fall short.

The Core Advantages of Ceramic PCB Materials

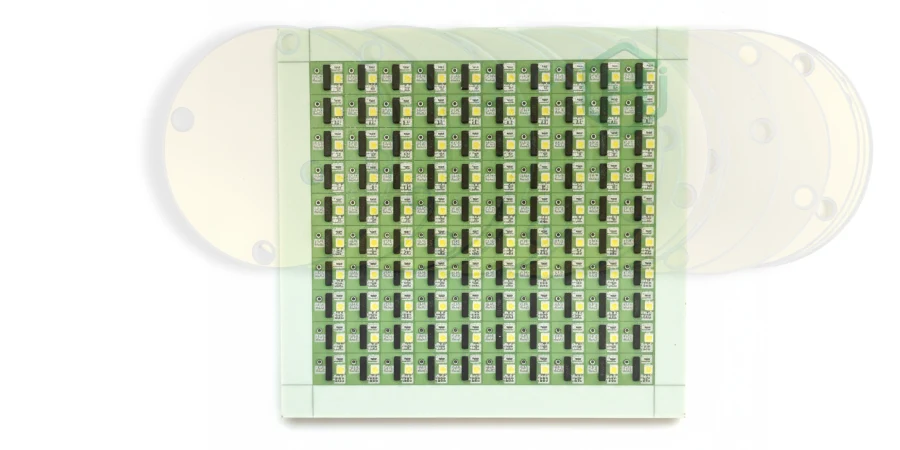

Ceramic PCBs are the material of choice for high-performance applications that demand superior heat dissipation and robust electrical insulation. Unlike organic laminates, advanced ceramics like Aluminum Oxide (Al₂O₃) and Aluminum Nitride (AlN) offer an exceptional combination of mechanical strength and low dielectric loss, making them ideal for RF, power, and LED modules.

Key Benefits Include:

- High Thermal Conductivity: With values ranging from 24 to over 180 W/m·K, ceramic substrates efficiently dissipate heat, ensuring stable operation and extending component life.

- Excellent Electrical Insulation: Superior dielectric strength and high insulation resistance make them perfect for high-voltage circuits.

- Low Coefficient of Thermal Expansion (CTE): A CTE closely matched to semiconductor materials like silicon minimizes mechanical stress during thermal cycling.

- Superior Environmental Resistance: Ceramics are chemically inert, providing robust performance in harsh industrial or medical environments.

- Unmatched Long-Term Reliability: They exhibit exceptional stability in high-vibration, high-humidity, or vacuum conditions.

These intrinsic properties make ceramic PCBs a foundational technology for mission-critical aerospace, automotive, medical, and industrial energy systems.

A Deep Dive into Core Manufacturing Technologies: DBC, DPC, & HTCC

HILPCB employs a range of specialized ceramic PCB processes to meet diverse design and performance targets. Each technology offers unique advantages tailored to specific power, frequency, and cost requirements. This section provides an in-depth look at these three core technologies.

1. Direct Bonded Copper (DBC)

The DBC process uses a high-temperature eutectic bond to fuse high-purity copper foil directly to a ceramic substrate (Al₂O₃ or AlN) at over 1000°C. This technique, which uses no adhesive, forms an atomic-level Cu-O eutectic bond between the copper and ceramic.

Core Advantages:

- Unmatched Adhesion Strength: The bond between the copper and ceramic is incredibly strong, capable of withstanding severe thermal shock and mechanical stress.

- Exceptional Current Capacity: With copper thickness easily ranging from 127µm to over 300µm, DBC can handle hundreds of amps of current.

- Excellent Thermal Cycling Reliability: The well-matched CTEs of copper and ceramic ensure structural integrity even after tens of thousands of temperature cycles.

Ideal Applications: DBC is the gold standard for high-power electronics, widely used in IGBT and MOSFET modules, electric vehicle inverters, solar power converters, and other high-power semiconductor devices requiring efficient heat removal.

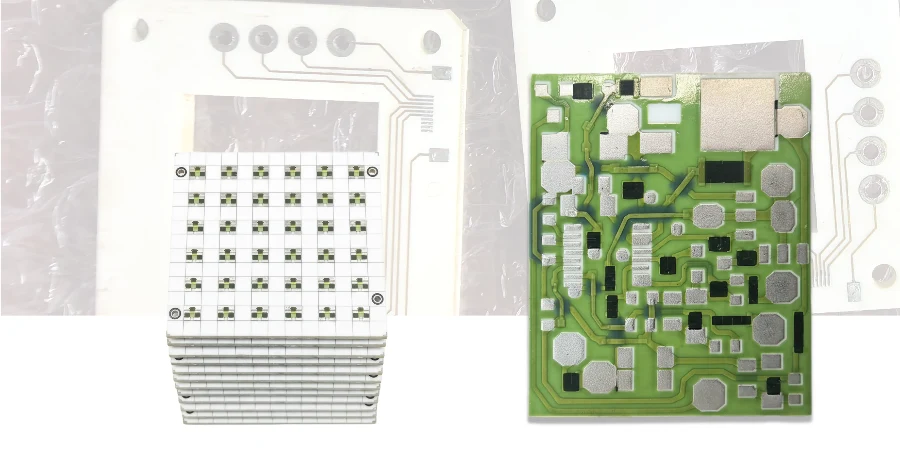

2. Direct Plated Copper (DPC)

DPC is an additive manufacturing technology based on thin-film processes. It begins by sputtering a thin copper seed layer onto the ceramic substrate. Circuit patterns are then defined using photolithography, and the copper is built up to the desired thickness via electroplating.

Core Advantages:

- Extremely High Precision: DPC can achieve very fine lines and spaces (down to 20µm) with sharp edge definition and excellent surface planarity.

- 3D Structure Capability: The process easily accommodates filled and plated-through vias for vertical interconnects, making it ideal for high-density packaging.

- Low-Temperature Process: The entire process is conducted at low temperatures, preventing any thermal damage to the substrate or embedded components.

Ideal Applications: DPC is the preferred choice for precision electronics and high-frequency applications, including RF/microwave circuits, high-density sensors, Chip-on-Board LEDs, and Thin Film PCB designs where precision is critical.

3. High-Temperature Co-Fired Ceramic (HTCC)

HTCC technology involves co-firing multiple layers of ceramic "green tape" with screen-printed refractory metal pastes (e.g., Tungsten, Molybdenum) at temperatures exceeding 1600°C. This creates a completely dense, monolithic, and three-dimensional circuit structure.

Core Advantages:

- Ultimate Mechanical Robustness: The sintered ceramic body is incredibly strong and can withstand extreme shock and vibration.

- Inherent Hermeticity: The monolithic structure is naturally hermetic, protecting internal circuitry from moisture and contaminants without needing a separate enclosure.

- Extreme Temperature Stability: HTCC circuits can operate reliably at continuous temperatures of 500°C and beyond.

Ideal Applications: HTCC is used in the most demanding environments where reliability is non-negotiable, such as aerospace electronics, automotive engine controllers, downhole drilling equipment, and implantable medical devices. For more details, see our guide on HTCC PCB technology.

| Feature | Direct Bonded Copper (DBC) | Direct Plated Copper (DPC) | High-Temp Co-Fired Ceramic (HTCC) |

|---|---|---|---|

| Core Process | High-Temp Eutectic Bonding | Sputtering + Electroplating | Multilayer Co-Firing |

| Conductor | Pure Copper (Cu) | Pure Copper (Cu) | Tungsten (W), Molybdenum (Mo) |

| Key Advantage | High Current, High Reliability | High Precision, High Density | Robust, Hermetic, High Temp |

| Primary Application | Power Electronics | RF, LED, Sensors | Aerospace, Harsh Environments |

Surface Preparation and Metallization

The long-term performance of any ceramic PCB depends heavily on the integrity of its metallization. Before copper or other conductive layers are applied, each substrate undergoes a precise surface conditioning process to ensure maximum adhesion and electrical reliability.

At HILPCB, we perform a multi-stage treatment sequence that includes ultrasonic particle removal, chemical degreasing, and plasma surface activation. This process not only eliminates surface contamination but also enhances wettability, ensuring uniform metal deposition across the ceramic substrate.

Depending on the application, different metallization approaches are used:

- Sputtering (PVD) or Evaporation: Ideal for DPC and thin-film circuits requiring ultra-fine conductive traces.

- Screen-Printed Thick Film Pastes: Suitable for HTCC and hybrid circuits using silver, gold, tungsten, or molybdenum systems.

- Electroplating and Electro-less Copper Deposition: Build-up copper thickness for high-current paths or multilayer interconnects.

After metallization, final surface finishes such as ENIG, ENEPIG, immersion silver, hard gold, or plated nickel-gold are applied. These finishes deliver superior solderability, oxidation resistance, and wire bond performance, ensuring robust downstream processes during Ceramic PCB Assembly and device packaging.

Design for Manufacturability (DFM) Guidelines

Design optimization plays a critical role in balancing electrical performance, mechanical stability, and cost efficiency during ceramic PCB fabrication. HILPCB’s engineering team collaborates closely with customers to integrate Design for Manufacturability (DFM) principles from the earliest stages of layout design.

Our goal is to transform your concept into a production-ready design that performs reliably under demanding electrical, thermal, and environmental conditions.

Key DFM Considerations

- Material Selection: Choose between Al₂O₃, AlN, or Si₃N₄ based on thermal, dielectric, and cost requirements.

- Thermal Path Engineering: Optimize copper area, via density, and substrate thickness for uniform heat dissipation.

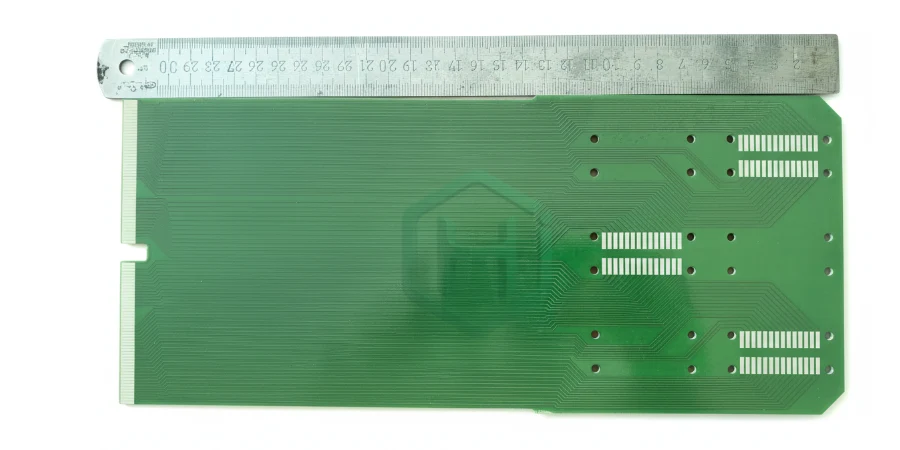

- Line Width and Spacing: Maintain geometric tolerances consistent with DBC or DPC resolution capabilities.

- Via and Interconnect Design: Use filled, plated, or laser-drilled vias to enhance current capacity and structural stability.

- Assembly Compatibility: Ensure pad geometry and surface finish support automated soldering and reflow processes.

Our DFM review process includes electrical modeling, mechanical stress simulations, and manufacturability audits to prevent production issues before they occur. This integrated approach guarantees that every project moving into Ceramic PCB Fabrication is efficient, repeatable, and compliant with both functional and reliability requirements.

Partner with HILPCB Factory for One-Stop Ceramic and Electronic Manufacturing Solutions

At HILPCB Factory, we go beyond ceramic PCB production — we provide a complete electronic manufacturing ecosystem. Our vertically integrated facilities combine PCB fabrication, assembly, and system integration under one roof, delivering efficiency, quality, and reliability for global OEMs.

We manufacture not only ceramic PCBs (DBC, DPC, HTCC) but also FR4, Rogers, metal-core, and flex-rigid PCBs, allowing seamless integration of multiple board types within a single device. Whether your project involves RF modules, power converters, or medical systems, we manage every stage with precision — from prototype validation to full-scale production.

Why Engineers Choose HILPCB

- Comprehensive Capability: PCB manufacturing, SMT and through-hole assembly, box build, and product housing integration.

- Technical Expertise: DFM/DFA engineering support for high-frequency, power, and mixed-material assemblies.

- Certified Quality: ISO 9001, IATF 16949, and AS9100 compliance for automotive, aerospace, and medical applications.

- Global Delivery: Fast prototyping and scalable production with strict quality traceability.

As your end-to-end manufacturing partner, HILPCB Factory helps bring your concepts to market faster — with proven performance, consistent quality, and simplified logistics.

Explore our full range of PCB and assembly capabilities on our Ceramic PCB Product Page or request a custom quote today.