Every successful product starts with a well-built prototype. At HILPCB, we help hardware teams turn design concepts into functional, production-ready circuit boards—fast. Our in-house circuit board fabrication and assembly lines deliver precise prototypes in as little as 48 hours, ensuring you validate, refine, and scale with confidence.

1. Why PCB Prototyping Is Critical

A working prototype is more than a test—it’s your proof of concept. It exposes real-world electrical, mechanical, and thermal performance, helping engineers:

- Verify circuit functionality

- Detect layout or signal integrity issues

- Test fit and compatibility with enclosures

- Confirm that the design can be manufactured efficiently

Skipping proper prototyping often leads to costly redesigns and delayed product launches. Our process ensures your design is validated before you commit to volume manufacturing.

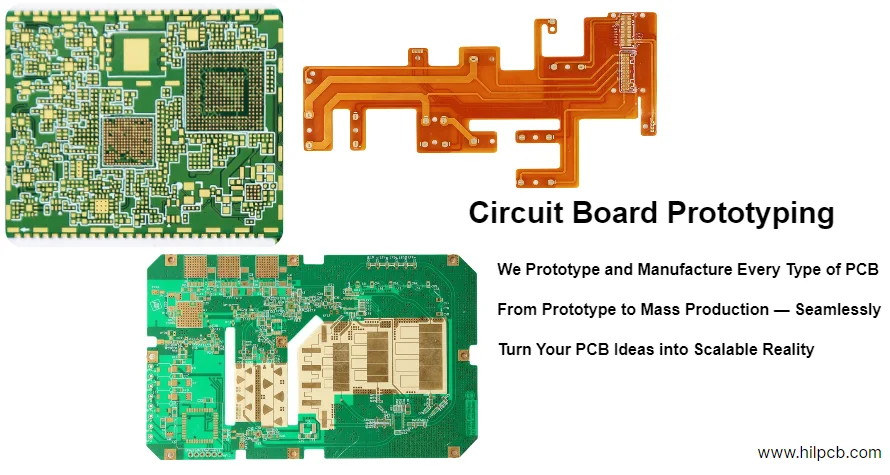

2. What Our Prototyping Service Includes

We build prototypes that replicate real production conditions—so what works in testing will work in production.

Capabilities:

- 1–64 layer boards, including HDI and multilayer stack-ups

- Fine-pitch traces down to 2/2 mil

- Rogers, FR4, and hybrid material options for RF and high-speed designs

- Controlled impedance, microvias, and buried/blind via options

- Optional conformal coating or protective finishes

Each prototype is fabricated using the same machines and processes as our circuit board manufacturing line, guaranteeing consistency from sample to final batch.

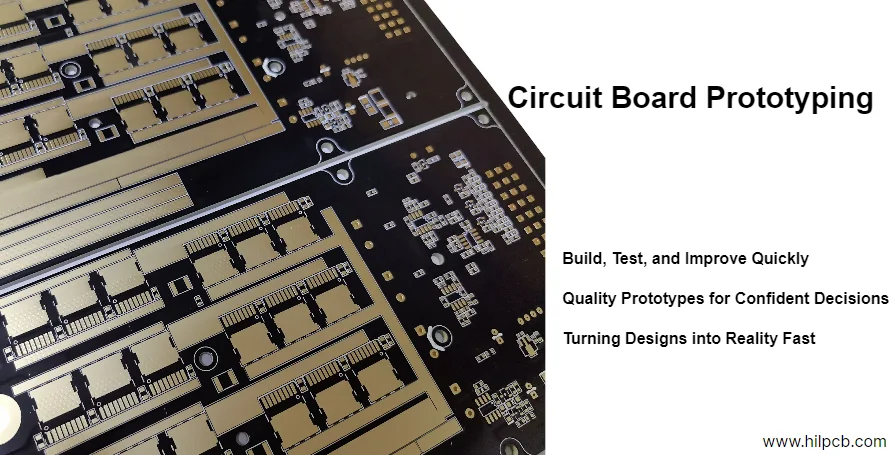

3. Rapid Turnaround for Fast-Moving Projects

When time-to-market matters, speed without compromise is essential. We provide express prototyping options with engineering review within 12 hours and delivery as fast as 48 hours.

Our digital workflow ensures:

- Real-time job tracking

- 24/7 process automation

- Direct communication with engineers for design clarification

You’ll know exactly when your board will be ready—and how it performs—before you move forward with mass production.

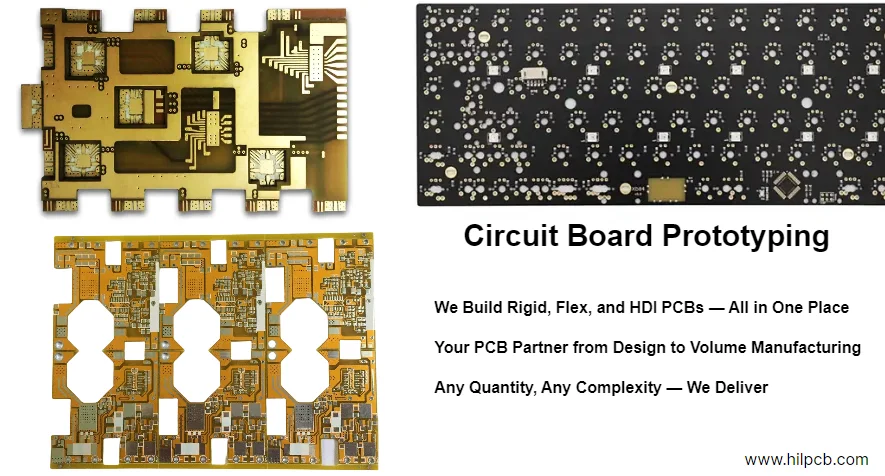

4. From Prototype to Mass Production — The Seamless Transition

This is the core advantage of HILPCB: we don’t just stop at prototypes. We help you move smoothly into full production without repeating setup or revalidation.

Here’s how we make it seamless:

a) Shared Data Environment

All parameters from your prototype—materials, stack-up, impedance, drilling patterns—are saved in our system. When you approve the design, these exact settings transfer automatically into production, eliminating rework and errors.

b) Unified Tooling and Process Calibration

Our circuit board factory uses the same calibration data, solder mask parameters, and lamination cycles for both prototype and production batches.

You get identical performance, whether you’re making ten boards or ten thousand.

c) Engineering Feedback for DFM (Design for Manufacturability)

Before scaling, our engineers perform a Design for Manufacturability review, suggesting improvements to reduce cost and improve reliability in mass production. This collaboration ensures your prototype isn’t just functional—it’s ready for manufacturing at scale.

d) Assembly Integration

Need your boards fully built for testing?

Our circuit board assembly division can populate components, solder, and perform functional testing under one roof. This end-to-end service saves time, reduces coordination errors, and keeps your product development cycle moving.

5. What Makes HILPCB Different

- Fast turnaround: 48-hour express service for urgent builds

- True production accuracy: Same process for prototypes and volume orders

- Flexible order sizes: From single units to pilot runs

- Direct communication: Real engineers, not just salespeople

- Global support: Trusted by clients in telecom, IoT, automotive, and industrial control

We’re not just fabricating PCBs — we’re helping teams bring ideas to market faster, with less risk.

Frequently Asked Questions

How fast can you deliver prototypes?

Standard prototypes take 3–5 days; express service delivers within 48 hours depending on design complexity.

Can you fabricate and assemble prototypes together?

Yes. We provide full turnkey service, including fabrication, component sourcing, and assembly.

Do you review files before production?

Absolutely. Our engineers perform a DFM check to ensure manufacturability and prevent costly issues.

Can my prototype data be reused for production?

Yes. We store your validated process data to ensure a smooth handoff to production with zero requalification.