Consumer electronics have transformed modern living—from mobile phones to smart home devices. Behind these innovations lies a core enabler: the printed circuit board. A well-designed PCB is essential for power efficiency, miniaturization, connectivity, and product longevity. At Highleap PCB Factory, we provide scalable PCB manufacturing and assembly services that meet the exacting needs of today’s compact and feature-rich devices.

What Makes Consumer Electronics PCBs Unique?

Unlike industrial or automotive PCBs, circuit boards in consumer electronics prioritize size, performance, and cost-efficiency. Devices are becoming smaller and more powerful, requiring tight integration of components and multi-functional circuit layers. Typical applications include:

- Smartphones, tablets, and laptops

- Smartwatches and wearable health monitors

- Wireless earbuds and audio devices

- Smart home systems and IoT hubs

- Game consoles and AR/VR gear

These devices rely on dense circuit designs, fast data transfer, and complex signal integrity management within highly constrained form factors.

Key Considerations in Consumer Electronics PCB Design

Designing a reliable consumer electronics PCB demands balance between electrical performance, manufacturability, and user-centered functionality. Major design priorities include:

- Compact layouts with high-density interconnects

- Controlled impedance for high-speed signals

- Lightweight and flexible materials for wearables

- EMI/EMC compliance and signal shielding

- Mechanical strength despite small geometries

- Thermal management in tightly enclosed spaces

To address these, advanced technologies like blind/buried vias, laser-drilled microvias, and stacked via structures are frequently used.

Common PCB Types in Consumer Electronics

| Device Category | PCB Type | Characteristics |

|---|---|---|

| Smartphones | HDI Multilayer PCB | Fine-pitch pads, via-in-pad, BGA support |

| Wearables | Flexible and Rigid-Flex PCB | Lightweight, bend-tolerant, dynamic flex zones |

| Audio Devices | 2–6 Layer Rigid PCB | Compact, cost-efficient, low noise |

| Smart Home Hubs | 4–8 Layer Mixed Signal PCB | Combines analog/digital domains, RF handling |

| Game Consoles | 8–12 Layer PCB with Power Planes | High current, EMI control, thermal balancing |

| Drones and UAVs | 6–10 Layer HDI or Rigid-Flex PCB | Lightweight, vibration-resistant, RF and GPS integration |

| Digital Cameras | 6–10 Layer Rigid PCB | EMI shielding, high-speed image processing, compact layout |

| Action Cameras | Rigid-Flex and HDI PCB | High durability, thermal control, space-efficient routing |

| Smart Glasses / AR Wearables | Ultra-thin Rigid-Flex PCB | Miniaturized, curved-fit, supports sensors and displays |

| Portable Health Monitors | 4–6 Layer Flexible PCB | Biocompatible options, wearable comfort, analog-digital integration |

Each category represents a distinct set of engineering challenges—from achieving ultra-thin profiles in smart glasses to building vibration-tolerant and RF-compatible boards for compact drones. At Highleap PCB Factory, our experience with diverse consumer product geometries allows us to support custom stack-ups, unusual board outlines, and application-specific signal requirements.

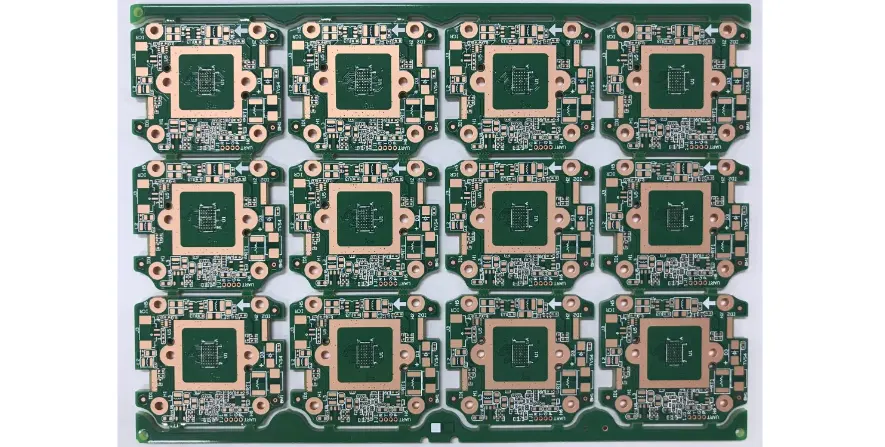

Advanced Capabilities at Highleap PCB Factory

Our facility is optimized for high-precision and complex builds. We specialize in a wide array of PCB types for consumer applications, including:

- HDI boards with stacked microvias and via-in-pad BGA layouts

- Rigid-flex circuits for dynamic bending use-cases

- Multilayer PCBs up to 60+ layers with impedance control

- High-frequency RF PCBs for Wi-Fi, Bluetooth, and 5G

- Aluminum PCBs for LED and thermally demanding products

- Lead-free and RoHS-compliant PCBs for global markets

For customers developing next-generation consumer tech, we offer DFM consulting, material selection guidance, and rapid prototyping—all aligned with international quality standards.

PCB Assembly for Consumer Electronics

PCB assembly in consumer products often involves ultra-miniature components such as 0201 chips, fine-pitch QFNs, and dense BGAs. Our SMT lines are equipped for:

- High-speed, high-precision component placement

- Solder paste inspection (SPI), AOI, and X-ray inspection

- Mixed technology assembly: SMD + through-hole

- Turnkey sourcing and supply chain support

We also support low-to-mid volume builds for R&D or early-stage product validation, and ramp to high volume production with consistent traceability and yield control.

Evolving Demands and Future Trends

As consumer expectations evolve, PCB technology must keep pace. Key emerging directions include:

- Integration of AI processors and edge computing modules

- Enhanced power delivery for fast charging and energy efficiency

- Multi-antenna and multi-band support for 5G and Wi-Fi 7

- Embedded sensors and haptics for immersive experiences

- Sustainable materials and recyclability for eco-conscious products

Highleap PCB Factory continuously invests in process refinement, testing automation, and advanced materials to meet the evolving needs of electronics brands worldwide.

Conclusion

Consumer electronics PCBs are at the heart of the modern digital experience. They demand miniaturized yet powerful designs, strict layout discipline, and robust manufacturing execution. At Highleap PCB Factory, we don’t just produce standard boards—we enable innovation through our expertise in complex and high-performance PCB manufacturing.

Whether you're building a next-gen smartwatch, an AI-enabled home device, or a high-speed audio system, we have the technology and experience to bring your concepts to life with speed, precision, and scale.