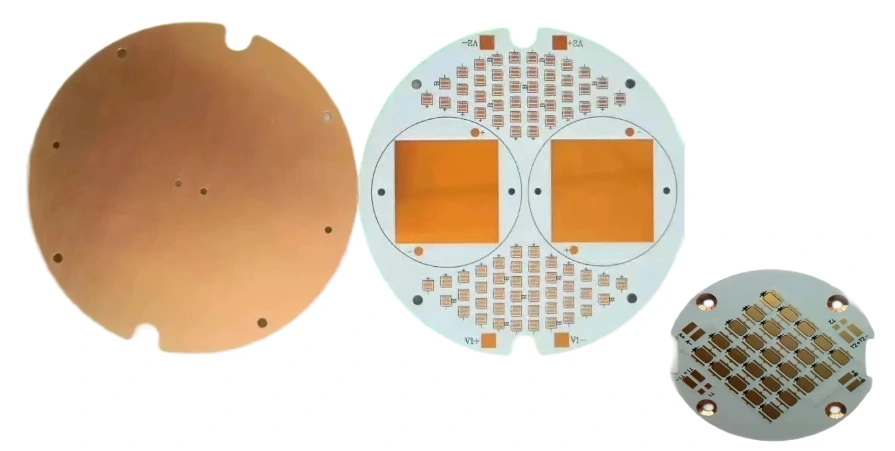

Copper core PCBs are purpose-built for efficient thermal management and reliable power handling. At Highleap PCB Factory, we specialize in the fabrication and assembly of custom copper core PCBs that meet tight tolerances and perform under thermal load. Whether you're designing for high-brightness LEDs, power converters, RF modules, or industrial motor drives, we manufacture and assemble boards using materials that move heat fast and stand up to demanding operating conditions.

To explore more categories, visit our PCB product overview or review our metal core PCB capabilities.

How We Build Reliable Copper Core PCBs

We focus on production quality, material pairing, and time efficiency. Key capabilities for copper core PCB production include:

- Copper base thickness from 0.5 mm to 5 mm

- High-conductivity copper alloys for maximum heat transfer

- FR4 + copper hybrid or full-metal stack-ups

- Selective insulation layers for single/multi-layer routing

- Thermal vias and direct-thermal-path design support

- Profile accuracy for complex outlines and aluminum integration

We work with engineers building automotive power modules, industrial lighting systems, and thermal-interface designs where copper base layers are critical for longevity.

Material Options and Application-Specific Design

Here’s a technical snapshot of materials and configurations we commonly use:

| Parameter | Options |

|---|---|

| Base Metal | Pure copper, C1100, mixed MCPCB |

| Insulation | FR4, polyimide, thermal prepregs |

| Conductive Layers | Single-sided, 2-layer, 4-layer with insulation + top routing |

| Surface Finishes | ENIG, HASL, OSP, Immersion Silver |

| Thermal Conductivity | > 3 W/m·K typical with copper substrate |

| Applications | LED lighting, power regulators, RF systems, energy devices |

We also support simulation or review of your heat path using our internal tools before committing to production.

End-to-End Manufacturing and Assembly for Copper Core PCBs

As a complete copper core PCB manufacturer and assembly provider, Highleap supports every step:

- File validation and stack-up assistance

- High-temperature solder masking and high-Tg prepreg application

- SMT/THT component placement on heat-managed zones

- AOI/X-ray for verification in thermal pad assembly

- International delivery in protected packaging

- PayPal, bank, or corporate billing supported

Use our Gerber Viewer and 3D PCB Viewer to check details before finalizing your order.

Built for Thermal Demands, Delivered with Speed

Quick-turn manufacturing doesn’t have to mean compromising on quality—especially when thermal performance is involved. Our copper core PCB production line supports 5–8 day fabrication for many configurations, with optional express shipping.

We’ve supported urgent deliveries for:

- LED module prototyping

- High-current charging interfaces

- RF amplifier boards

- Motor controller development boards

- Energy distribution backplates

Our team is experienced with special material handling and fast DFM feedback for custom thermal applications.

Design Flexibility and Specialized Engineering Support

Copper core PCBs are rarely off-the-shelf builds. At Highleap, our team routinely supports designs that push the limits of thermal management, mechanical strength, or non-standard geometries. We work with mechanical engineers, thermal analysts, and electrical layout teams to ensure manufacturability without compromising performance.

We help you make trade-offs between base copper thickness, dielectric spacing, and routing constraints. Need a mixed dielectric stack-up for combined RF and power functionality? We can do that. Have edge-mounted components requiring milled cutouts in the copper plate? We’ll machine to spec.

Our engineering support includes:

- Thermal simulation input during the stack-up phase

- Sizing advice for thermal vias and pad isolation

- Routing reviews to avoid signal discontinuities over insulated gaps

- Multi-zone stack-ups for boards needing both FR4 logic and copper-core power zones

Highleap’s ability to fabricate these configurations comes from careful thermal lamination, clean mechanical processing, and alignment control during drilling and plating.

Conclusion

If you're searching for a copper core PCB manufacturer who can support high-performance, thermally sensitive designs—Highleap PCB Factory is ready. From specialty laminates to precision-controlled stack-ups, we handle what standard PCB factories often can't.

We’re a trusted copper core PCB assembly provider as well, ensuring thermal pads, connectors, and surface finishes are placed and tested under production-grade controls. Our service includes fast response, secure delivery, and flexible support for clients in LED, power, and energy segments.

Let’s build your next high-reliability thermal solution—fast, accurate, and built for scale. Whether your product is a compact LED lamp driver or an industrial motor controller operating in harsh conditions, we’ll help you bring it to life with confidence.