In modern electronics, where compact size and high power density drive design innovation, custom aluminum PCB manufacturing has become a key enabler for superior thermal management and product reliability. Unlike standard FR4 boards, aluminum-based PCBs combine mechanical stability, efficient heat dissipation, and design flexibility — making them ideal for LED lighting, automotive, power, and RF applications.

At HILPCB, we don’t just produce aluminum PCBs — we deliver complete PCB manufacturing and assembly solutions, including FR4, HDI, rigid-flex, ceramic, and metal-core PCB fabrication. Our engineering team collaborates closely with clients to create customized designs that balance performance, manufacturability, and cost. From prototyping to mass production, we ensure every board meets your specific electrical, thermal, and environmental requirements.

1. Why Choose Custom Aluminum PCB Manufacturing

When product performance depends on heat dissipation or mechanical stability, standard PCBs can’t keep up.

Custom aluminum PCBs deliver:

- Enhanced thermal management for high-power LED, RF, and power electronics

- Integrated mechanical structures such as cavities or mounting holes for compact systems

- Optimized electrical routing combining high-current paths and controlled impedance traces

- Improved reliability in automotive and industrial environments

These benefits make custom aluminum PCBs essential for industries where efficiency, safety, and durability define competitiveness.

2. Material and Design Customization Options

Material selection defines both thermal efficiency and cost-effectiveness.

Manufacturers offer a wide range of customization options:

- Base Metal Choices: Aluminum (5052, 6061, 1100) for balanced cost and performance, copper substrates for extreme heat transfer, and composite alloys for hybrid systems.

- Dielectric Layers: From 1–8 W/mK thermal conductivity, balancing insulation and heat conduction for high-thermal PCBs.

- Copper Weights: 1–10 oz, with mixed regions for localized current demands — common in HDI PCB and power modules.

- Surface Finishes: ENIG, HASL, and immersion silver for solder reliability, plus selective gold plating for connectors or contact pads.

- Solder Mask Colors: White for LED reflection, black for visual contrast, and high-temperature options for industrial applications.

Custom aluminum PCB design also enables multi-layer and hybrid FR4–metal configurations, combining thermal control with dense routing capability.

3. Advanced Fabrication and Assembly Techniques

Modern fabrication methods transform design freedom into production reality.

Advanced processes include:

- Hybrid Multilayer Lamination: Merging FR4 signal layers with aluminum bases for superior heat spreading.

- Cavity and Embedded Designs: Allowing thick components or optics while maintaining low profile.

- Selective Plating and Masking: Custom finishes for power and signal zones to balance cost and performance.

- Thermal Simulation and FEA: Predicting hot spots and optimizing via arrays before manufacturing.

- Integrated Assembly Services: Combining SMT assembly and box-build assembly for a single turnkey production flow.

These techniques enable high-precision builds for power supplies, EV modules, RF systems, and LED arrays with tight performance tolerances.

4. Industry Applications and Performance Advantages

Custom aluminum PCB solutions are widely used in specialized sectors that demand durability, performance, and precision:

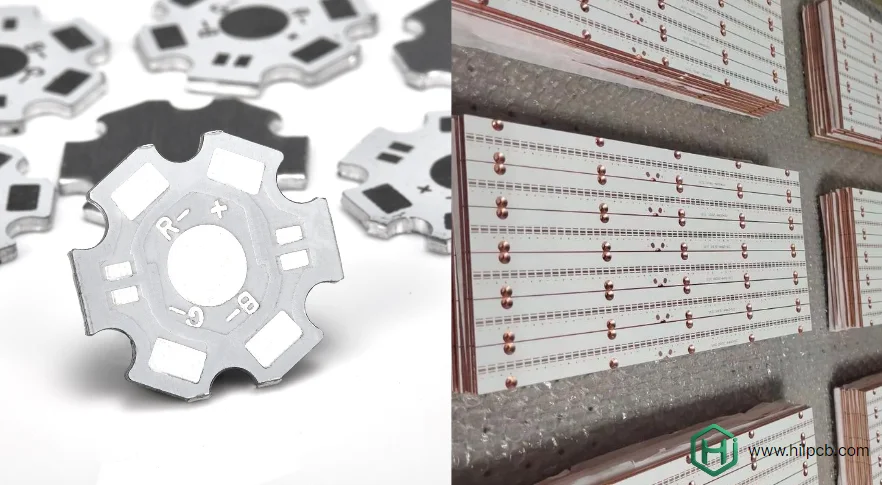

- LED Lighting Systems: High thermal conductivity materials, reflective coatings, and optimized copper patterns enhance brightness and lifespan.

- Automotive Electronics: IATF 16949 quality, vibration-resistant bonding, and chemical protection for ECUs, BMS, and lighting systems.

- Power Electronics: Heavy copper, high isolation (>3kV), and hybrid control circuits for converters and motor drives.

- Medical & Scientific Devices: Ultra-stable heat profiles and ISO 13485 manufacturing for diagnostics and instrumentation.

- RF & Microwave Equipment: Controlled impedance, cavity designs, and low-loss surfaces for high-frequency PCBs and radar systems.

Each sector benefits from tailored engineering that translates directly into better thermal balance, reliability, and long-term value.

5. Engineering Collaboration and Long-Term Value

Custom PCB success relies on close cooperation between the designer and manufacturer.

At HILPCB, we support clients from concept to mass production through:

- Early DFM & DFT Reviews: Prevent manufacturing issues and optimize layouts.

- Rapid Prototyping: 5–10 day turnarounds to validate concepts quickly.

- Material Lifecycle Management: Ensuring long-term supply and availability for specialized materials.

- IP Protection: NDAs and dedicated production lines for confidential projects.

- Continuous Improvement: Ongoing process refinement and yield enhancement across production runs.

Custom aluminum PCB manufacturing offers more than unique geometry or materials — it delivers measurable value through performance optimization, cost efficiency, and reliable scalability.

Conclusion

Custom aluminum PCB manufacturing represents the intersection of precision engineering, thermal innovation, and scalable production. It’s not limited to aluminum substrates — it’s part of a complete ecosystem of advanced PCB solutions that adapt to diverse design and performance needs.

At HILPCB, we integrate PCB fabrication, PCB assembly, and testing under one quality-controlled system. Whether it’s aluminum, FR4, HDI, ceramic, or rigid-flex PCBs, our manufacturing expertise ensures consistent performance, fast lead times, and full traceability across every production run.

With strong engineering collaboration, global delivery capabilities, and flexible production scales — from small-batch prototypes to large-volume manufacturing — HILPCB stands as your trusted custom PCB manufacturer in China, delivering optimized designs for any thermal, electrical, or mechanical challenge.