In an era where electronics must withstand constant movement, static circuit designs cannot deliver the reliability modern applications demand. At HILPCB, we are a specialized PCB manufacturing facility with deep expertise in dynamic flex PCB engineering—circuits specifically designed to endure continuous, repetitive motion throughout their operational lifetime, from industrial robotics to medical imaging equipment where failure is not acceptable.

Our comprehensive capabilities encompass advanced material selection, precision manufacturing processes, and rigorous testing protocols ensuring your dynamic flex circuits achieve 100,000 to 1,000,000+ flex cycles without degradation.

Dynamic Flex PCB Material Science and Construction

Dynamic flex PCB technology demands fundamentally different materials and design approaches compared to bendable PCB circuits that may flex only during installation. The continuous mechanical stress of repeated flexing requires specialized engineering at every level.

Critical Material Requirements

Substrate Selection: High-performance polyimide films exclusively (polyester inadequate for dynamic applications):

- Controlled elongation properties (typically 40-70% elongation at break)

- Dimensional stability across temperature extremes

- Tear propagation resistance preventing crack growth

- Chemical resistance to cleaning agents and operating environments

Copper Specifications: Rolled annealed copper mandatory (electrodeposited copper fails under dynamic stress):

- Grain structure optimized for fatigue resistance

- Annealing process relieving internal stresses

- Typical thickness: 0.5oz (18μm) or ½oz (9μm) for maximum flexibility

- Ductility specifications ensuring elongation capability

Adhesive Systems: Adhesiveless constructions preferred for maximum reliability:

- Eliminates adhesive degradation as failure mode

- Reduces total thickness improving flex performance

- Better thermal properties for power applications

- Premium cost (20-40% over adhesive-based) justified by reliability

Coverlay Protection: Flexible polyimide coverlay with high-bond adhesives:

- Maintains adhesion through millions of flex cycles

- Prevents copper exposure and oxidation

- Chemical resistance for harsh environments

- Thickness optimization balancing protection vs. flexibility

Specialized Manufacturing for Dynamic Applications

Advanced Fabrication Processes

HILPCB's dynamic flex PCB manufacturing incorporates technologies specifically optimized for continuous motion reliability:

Rolled Copper Processing:

- Sourcing from certified suppliers with documented grain structure

- Incoming material testing verifying elongation properties

- Annealing optimization relieving manufacturing stresses

- Quality verification through metallurgical analysis

Precision Circuit Formation:

- Fine-line photolithography achieving 75μm traces and spaces

- Controlled etching preventing copper stress concentration

- Post-etch annealing when specified for critical applications

- HDI PCB capabilities for maximum routing density

Coverlay Lamination:

- Vacuum lamination preventing air entrapment

- Pressure and temperature optimization for superior bond strength

- Adhesion testing exceeding IPC-6013 specifications

- Selective coverlay designs optimizing flexibility

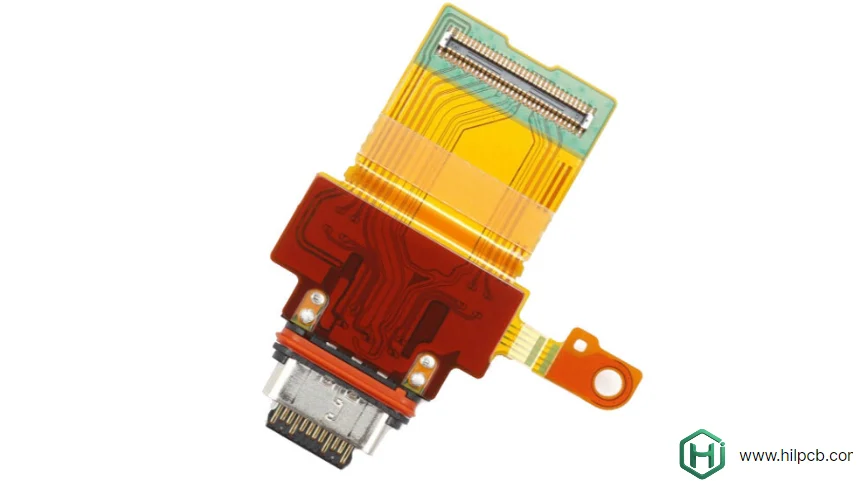

Stiffener Integration: Strategic reinforcement in static zones:

- Polyimide stiffeners for lightweight applications

- FR4 PCB stiffeners for component mounting

- Stainless steel for extreme mechanical loads

- Precision placement (±0.1mm) ensuring proper support

Assembly Considerations

SMT assembly for dynamic flex demands specialized approaches:

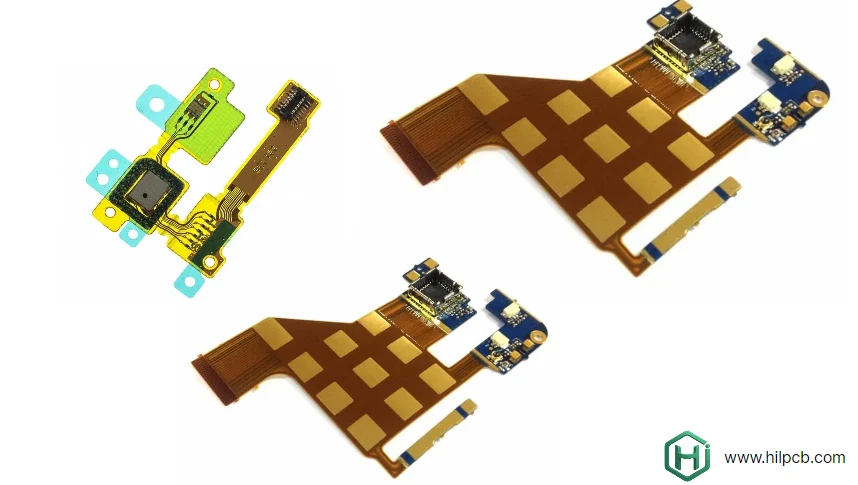

Zone Classification:

- Static Zones: Component placement, connectors, rigid features

- Transition Zones: Gradual stiffness changes, strain relief features

- Dynamic Zones: Absolutely no components, vias, or rigid elements

Fixturing Design: Custom fixtures support ultra-flexible substrates:

- Vacuum or mechanical hold-down preventing warping

- Support throughout reflow preventing component displacement

- Accessibility for placement and inspection equipment

- Release mechanisms preventing substrate damage

Our turnkey assembly services include complete supply chain management from bare dynamic flex PCB through final product testing and certification.

Critical Application Categories

Dynamic flex PCBs are essential in motion-intensive and space-limited systems where reliability and longevity matter most. HILPCB provides precision dynamic-flex PCB manufacturing and assembly for diverse industrial, medical, and commercial applications — ensuring durable performance under continuous bending and vibration.

Industrial & Automation

Used in robotic arms, CNC machines, automated assembly systems, and other high-duty-cycle environments demanding millions of flex cycles, EMI shielding, vibration resistance, and integration with heavy copper PCBs for power circuits.

Medical & Healthcare

Critical in ultrasound probes, diagnostic instruments, endoscopic equipment, and wearable or portable medical devices, where biocompatibility, sterilization endurance, and high-frequency PCB performance ensure accurate, safe, and consistent operation.

Commercial & Office Equipment

Applied in printers, scanners, and imaging systems requiring reliable interconnects for high-speed data, precise signal timing, and repetitive motion — maintaining quality and minimizing downtime in continuous-use devices.

From robotics to medical imaging, HILPCB’s dynamic flex PCB solutions deliver proven flexibility, signal stability, and mechanical endurance tailored to your application’s motion and reliability needs.

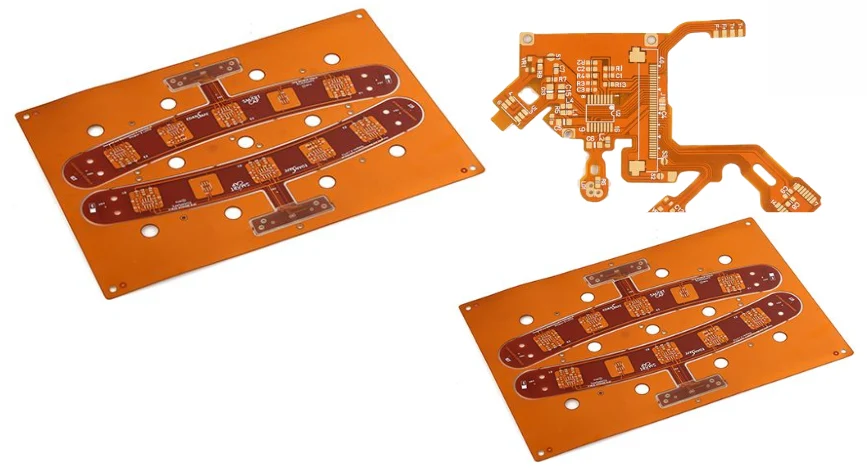

Cost Optimization and Production Scaling

Flexible circuits generally cost more per unit area than rigid PCBs due to higher material and processing expenses. However, at the system level, they often lower total cost by removing connectors, cables, and manual assembly, while enabling thinner, lighter, and more compact product designs. Effective cost control requires balancing performance targets with budget constraints to ensure both reliability and manufacturability.

Design for manufacturability (DFM) remains the key to cost reduction. Optimizing routing to minimize layer count and maximize panel utilization significantly lowers production costs. Using standard materials, thicknesses, and finishes avoids unnecessary premiums without compromising function. As production scales, per-unit costs decrease—prototypes emphasize flexibility and low setup costs, while mass production benefits from automation and custom tooling. HILPCB supports projects from one-off prototypes to high-volume runs with tailored pricing and scalable manufacturing capacity.

Frequently Asked Questions — Dynamic Flex PCB

Q1: What is the difference between dynamic flex PCB and standard flexible PCB?

A: Dynamic flex PCB is specifically engineered for continuous, repetitive motion throughout operational life, using rolled annealed copper and specialized designs. Standard flex PCB may flex during installation but doesn't require continuous cycling endurance. Material requirements and design rules differ significantly.

Q2: How many flex cycles can dynamic flex PCBs achieve?

A: Well-designed dynamic flex circuits achieve 100,000 to 1,000,000+ cycles depending on bend radius, material selection, and environmental conditions. Industrial robotics applications requiring millions of cycles demand conservative design parameters and premium materials.

Q3: Can components be placed in dynamic flex zones?

A: No. All components, connectors, vias, and rigid features must locate in static zones only. The dynamic flex section must remain completely clear of any rigid elements. Rigid-flex PCB designs combine rigid component areas with dynamic interconnects.

Q4: What factors affect dynamic flex PCB cost?

A: Primary cost drivers include: rolled annealed copper specifications, adhesiveless vs. adhesive construction, layer count, minimum bend radius requirements, and production volume. Reliability testing and certification requirements also impact total project cost.

Q5: How does HILPCB validate dynamic flex PCB reliability?

A: We perform comprehensive testing including: flex endurance testing at specified radii and cycle counts, temperature cycling during flexing, humidity exposure, vibration combined with flex motion, and electrical monitoring throughout all testing. Testing follows IPC-6013 Type 3 specifications with customer-specific requirements when applicable.