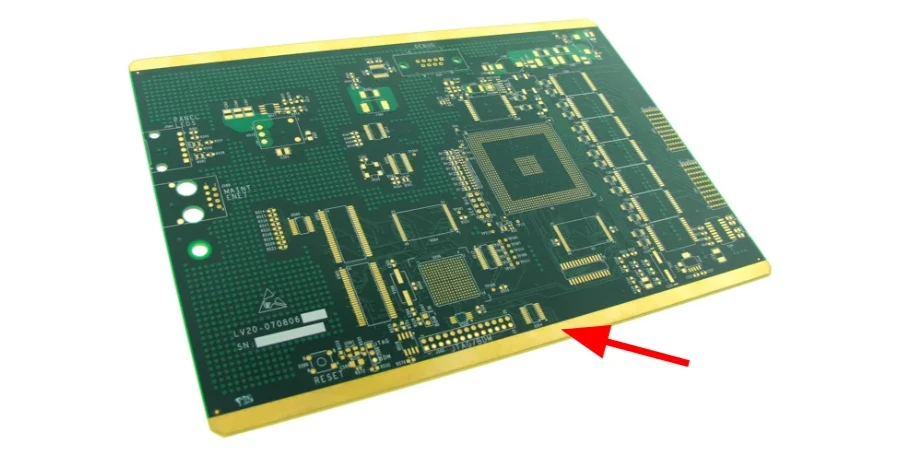

Edge plated PCBs are a specialized design where the PCB edges are plated with metal to facilitate electrical connections, ensuring reliable interconnects between the PCB and other components or systems. This technology is particularly useful for high-performance applications such as power electronics, telecom systems, and high-frequency circuit boards, where standard surface mount connections may not provide the necessary performance or reliability.

At Highleap PCB Factory, we specialize in the design and manufacture of Edge Plated PCBs, integrating high-quality materials and precision processes to meet the rigorous requirements of industries like telecommunications, aerospace, automotive, and medical devices. Whether for a high-speed computing board or a custom connector solution, our edge plated PCB solutions offer both electrical reliability and mechanical durability.

What is Edge Plating in PCBs?

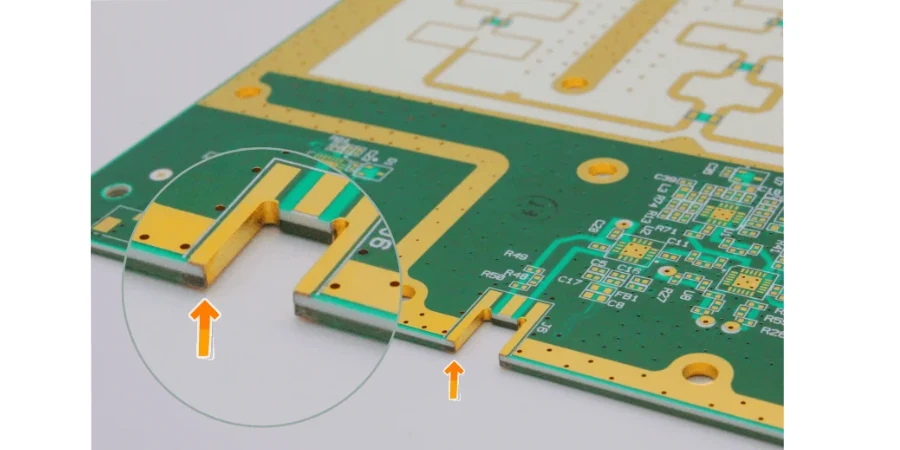

Edge plating refers to the process of applying metal plating to the edges of a PCB. This creates a conductive layer that can serve as an electrical interface for other components or PCBs, facilitating robust and high-speed interconnects. Edge plated PCBs are particularly useful in applications where surface-mount or through-hole connections are impractical, or when enhanced signal integrity is required.

The edge plating process is typically done with materials such as gold, copper, or silver. These materials are selected for their conductivity and durability, ensuring long-term performance even in harsh or high-stress environments.

Applications of Edge Plated PCBs

Edge plated PCBs are commonly used in high-performance, space-constrained applications, including:

- Telecommunication Systems: Edge plated PCBs are ideal for connecting modules in telecom backplanes or high-frequency interconnects.

- Aerospace and Defense: In aerospace and defense applications, reliability and performance are critical. Edge plating provides durable and low-resistance connections in avionics, radar, and communication systems.

- Power Electronics: Power supply boards often require edge plating to facilitate high-current carrying capacity and low-resistance pathways for efficient energy transmission.

- High-Speed Computing: For computing systems, such as GPUs, edge plated PCBs enable high-speed data transfer and minimal signal degradation.

- Medical Devices: Edge plated PCBs are used in medical equipment where signal integrity and reliability are paramount, such as in diagnostic tools and surgical devices.

These applications benefit from the low-resistance, high-reliability connections provided by edge plating, ensuring optimal performance over long periods.

Highleap PCB Factory's Expertise in Edge Plating

At Highleap PCB Factory, we offer a range of services to ensure that your edge plated PCB meets the highest standards:

- Advanced Materials: We use a variety of materials, including high-Tg PCB, metal-core PCBs, and specialized laminates, to ensure that the edge-plated boards meet thermal, electrical, and mechanical performance criteria.

- Precision Edge Milling: We utilize precision milling and laser etching techniques to create clean, consistent edges that are ready for plating, ensuring that the plating adheres properly and provides reliable connections.

- Plating Process Control: Our plating processes are carefully monitored to ensure uniform coverage and proper adhesion of metals to the edges, including copper, gold, and silver for different application needs.

- Testing and Verification: Each edge plated PCB undergoes rigorous testing to ensure proper electrical connectivity, mechanical strength, and compliance with industry standards. This includes full 3D PCB Viewer simulations and real-time verification.

Our state-of-the-art manufacturing process ensures that every edge plated PCB we deliver is precisely engineered and thoroughly tested.

Why Choose Highleap PCB Factory for Your Edge Plated PCB Needs?

At Highleap PCB Factory, we stand out for our expertise and precision in edge plating. Our key advantages include:

- Custom Solutions: We provide tailored solutions to meet the unique design and performance requirements of your edge plated PCB, whether for prototype or high-volume production.

- Advanced Manufacturing Techniques: Our process includes cutting-edge PCB manufacturing techniques, ensuring that every PCB is fabricated with high precision and consistent quality.

- Reliability and Durability: We focus on creating PCBs that provide long-term reliability in harsh environments, with robust edge plating that ensures a high-quality, low-resistance connection.

- On-time Delivery: We offer quick turnaround times without compromising on quality, ensuring that your project is completed on schedule.

- Global Support: We support customers worldwide with technical assistance, prompt responses, and reliable shipping.

Whether you need a small batch for prototyping or large-scale production runs, Highleap PCB Factory provides reliable, high-performance edge plated PCBs for any application.