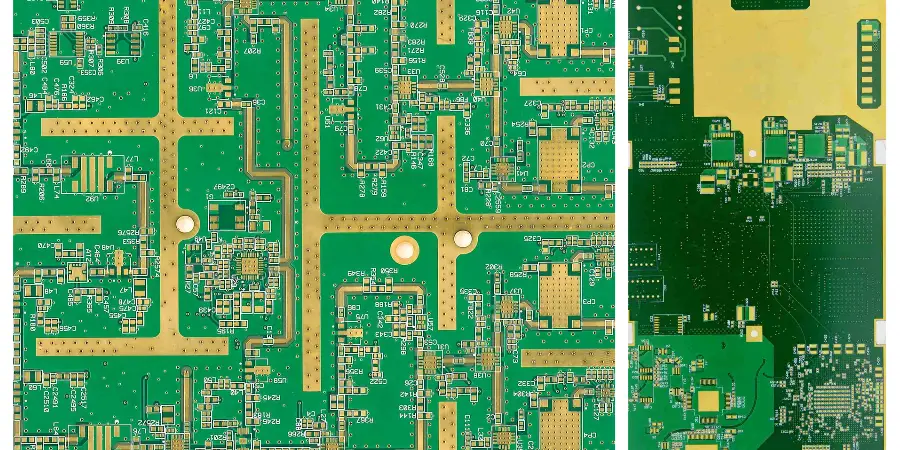

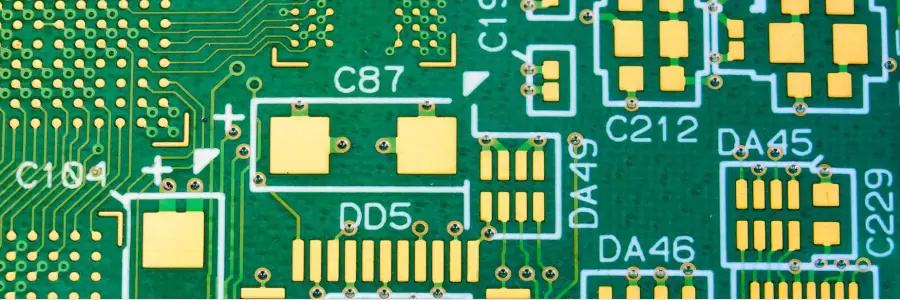

At Highleap PCB Factory (HILPCB), we are a comprehensive PCB manufacturing company specializing in a wide range of PCB technologies. We excel in producing complex PCBs, high-frequency PCBs, and offer full PCB assembly services. Our expertise covers a variety of surface finishes, including ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), ensuring that your electronic applications benefit from the highest quality standards in performance, reliability, and durability. Whether you're designing cutting-edge consumer electronics or industrial systems, we have the capabilities to meet your diverse PCB manufacturing needs.

Why Choose ENEPIG for Your PCB Manufacturing?

ENEPIG is one of the most advanced surface finishes available today, offering a combination of nickel, palladium, and gold that provides significant benefits over traditional surface finishes such as HASL or ENIG. With exceptional mechanical, electrical, and corrosion-resistant properties, ENEPIG is particularly suited for demanding industries like semiconductor packaging, medical devices, and automotive electronics.

Key Advantages of ENEPIG:

- Superior Solderability: The combination of nickel, palladium, and gold offers excellent wetting properties, ensuring strong, reliable solder joints.

- Corrosion Resistance: The palladium layer adds enhanced resistance to corrosion, ensuring long-lasting performance in harsh environments.

- Wire Bonding Capability: Palladium facilitates high-quality wire bonding, which is essential for microelectronics and semiconductor packaging.

- Durability: The multi-layer structure offers a highly durable surface, making it ideal for applications with high mechanical stress, such as connectors and contacts.

ENEPIG PCB Surface Treatment Technology

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) represents the most advanced PCB surface finish technology, engineered specifically for high-reliability wire bonding and fine-pitch soldering applications. This tri-metal deposition system creates a precisely controlled intermetallic structure that optimizes both solderability and wire bonding performance.

The process consists of three critically engineered layers:

Electroless Nickel (EN) Layer [3-6 µm]

- Phosphorus content precisely controlled (6-9%) for optimal interfacial strength

- Provides diffusion barrier preventing copper migration

- Uniform thickness distribution across features regardless of current density

- Creates stable Ni3Sn4 intermetallic compounds during soldering

Electroless Palladium (EP) Layer [0.05-0.15 µm]

- Acts as diffusion barrier between nickel and gold

- Prevents nickel oxidation and "black pad" phenomenon

- Enhances wire bondability through formation of stable Pd-Au intermetallics

- Enables fine-pitch component placement with minimal solder bridging

Immersion Gold (IG) Layer [0.025-0.075 µm]

- Self-limiting deposition ensures consistent thickness

- Prevents oxidation while maintaining flat soldering surface

- Forms reliable Au-Al intermetallic bonds in wire bonding

- Extended shelf life >12 months with proper storage

ENEPIG technology requires precise process control, with real-time monitoring of bath chemistry, temperature, and contamination to ensure optimal conditions. It excels in high-reliability applications like aerospace, medical devices, and RF circuits, offering superior solderability with lead-free alloys, robust wire bond strength, and performance in fine-pitch (<0.4mm) designs. Rigorous quality assurance protocols, including XRF thickness measurements, wire bond pull testing, and wetting balance tests, guarantee each ENEPIG PCB meets the highest standards, providing a reliable foundation for advanced electronic assemblies.

Applications of ENEPIG PCB

ENEPIG is suitable for a wide range of applications, particularly where performance and reliability are critical. Some common uses include:

- Semiconductor Packaging: ENEPIG is widely used in wire bonding for semiconductor components due to its excellent wire bonding surface.

- Automotive Electronics: The durability and corrosion resistance of ENEPIG make it ideal for automotive electronics exposed to harsh conditions.

- Medical Devices: ENEPIG provides a reliable, corrosion-resistant surface, making it a top choice for critical medical devices.

- High-Frequency RF Circuits: ENEPIG is optimal for high-frequency applications due to its smooth surface and superior performance at high speeds.

- Consumer Electronics: With its fine-pitch capabilities, ENEPIG is increasingly used in modern consumer electronics, offering better performance in compact designs.

Why HILPCB for ENEPIG PCB Manufacturing?

At Highleap PCB Factory (HILPCB), we provide tailored ENEPIG PCB manufacturing solutions that meet your specific performance and reliability requirements. Our experienced engineers ensure that each PCB is manufactured with the highest precision and quality.

- Customization: We offer ENEPIG solutions for both simple and complex PCB designs, including multilayer PCBs and high-frequency PCBs.

- Competitive Pricing: Despite the premium nature of ENEPIG, we offer competitive pricing for high-performance PCBs that doesn’t compromise on quality.

- Full-Spectrum Support: From design optimization to assembly, we provide complete solutions that ensure your ENEPIG PCBs meet the highest standards.

ENEPIG vs Other Surface Finishes

When comparing ENEPIG with other finishes like HASL and ENIG, ENEPIG offers several distinct advantages:

| Feature | ENEPIG | ENIG | HASL |

|---|---|---|---|

| Solderability | Excellent | Excellent | Good |

| Corrosion Resistance | High | Moderate | Low |

| Wire Bonding Capability | Excellent | Limited | Not Suitable |

| Durability | Very High | Moderate | Low |

| Cost | Higher than HASL | Similar to ENEPIG | Lower than ENEPIG |

ENEPIG offers superior performance in terms of corrosion resistance, wire bonding, and durability, making it the ideal choice for applications in demanding environments.

ENEPIG PCB Design Guidelines

When designing for ENEPIG processing, it is important to consider the following factors:

- Pad Design: For fine-pitch components like BGAs and QFPs, reduce pad sizes by 5-10% compared to ENIG designs.

- Component Placement: ENEPIG is particularly suitable for fine-pitch components, but areas requiring selective finishing may need special attention.

- Thermal Management: ENEPIG processing involves elevated temperatures, so it’s important to use high-Tg FR-4 materials to avoid thermal-related issues like delamination.

- Via Design: Vias larger than 0.5mm may trap excess solder, so make adjustments in your design to prevent solder wicking.

Quality Control and Reliability Testing for ENEPIG PCBs

At HILPCB, we ensure that all ENEPIG PCBs are manufactured to the highest standards. Our quality control processes include:

- Incoming Material Verification: We ensure that the solder alloy and PCB substrates meet all necessary specifications.

- Process Control Monitoring: Real-time monitoring of temperatures, pressure, and coating thickness ensures consistent quality.

- Solderability Testing: We use wetting balance testing to ensure excellent solder joint quality.

- Environmental Testing: We subject ENEPIG PCBs to a range of tests, including thermal cycling, humidity exposure, and mechanical stress tests, to validate their durability in real-world applications.

FAQ

What are the key benefits of ENEPIG over other finishes? ENEPIG offers superior corrosion resistance, excellent wire bonding properties, and high durability, making it ideal for high-performance applications in harsh environments.

Can ENEPIG be used for fine-pitch components? Yes, ENEPIG is perfect for fine-pitch components, offering a smooth, even surface that ensures reliable solder joints.

How does ENEPIG compare to ENIG? ENEPIG provides better wire bonding capabilities and is more durable, particularly in high-reliability applications. ENIG, however, may be preferred for cost-sensitive designs.

What industries use ENEPIG? ENEPIG is widely used in semiconductor packaging, automotive electronics, medical devices, and high-frequency applications, among others.

How do I specify ENEPIG in my design files? Specify "ENEPIG per IPC-4552" in your design documentation to ensure the proper finish is applied during manufacturing. You can also include specific area requirements for selective finishing if needed.

For more information or to get a quote for your ENEPIG PCB needs, don't hesitate to contact us.