At Highleap PCB Factory (HILPCB), we specialize in manufacturing high-quality epoxy PCBs that meet the demanding requirements of modern electronics. Our advanced production capabilities and experienced engineering team deliver reliable epoxy resin circuit boards for diverse applications, from consumer electronics to industrial control systems.

Understanding Epoxy PCB Technology and Material Properties

Epoxy PCBs represent the backbone of modern electronics manufacturing, utilizing glass-reinforced epoxy resin laminates that provide exceptional mechanical strength and electrical insulation. The most common epoxy PCB material, FR-4, combines woven fiberglass cloth with flame-retardant epoxy resin to create a substrate with a glass transition temperature (Tg) ranging from 130°C to 180°C. This composite structure delivers consistent dielectric properties (typically 4.5 at 1MHz), excellent dimensional stability, and reliable performance across a wide temperature range.

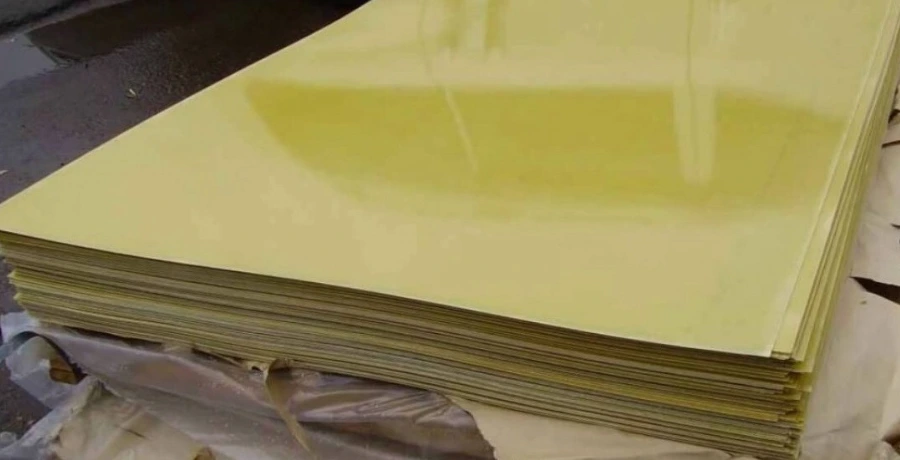

Our epoxy circuit board manufacturing processes accommodate various epoxy resin systems including standard FR-4, mid-Tg epoxy (150°C), high-Tg epoxy formulations (170°C+), and halogen-free epoxy laminates. The versatility of epoxy PCB materials allows optimization for specific applications - from cost-sensitive consumer products using standard epoxy to high-reliability automotive systems requiring enhanced thermal performance. We maintain comprehensive material inventories from leading suppliers like Isola, Panasonic, and Shengyi, ensuring consistent quality and rapid production starts.

The molecular structure of cured epoxy resin creates a three-dimensional crosslinked network that provides superior adhesion to copper foils, critical for maintaining circuit integrity through thermal cycling and mechanical stress. Modern epoxy PCB formulations incorporate various fillers and modifiers to enhance properties such as thermal conductivity, coefficient of thermal expansion matching, and moisture resistance. Our engineering team leverages decades of experience with epoxy laminate PCBs to recommend optimal material selections based on your electrical, thermal, and mechanical requirements.

Comprehensive Epoxy PCB Manufacturing Capabilities

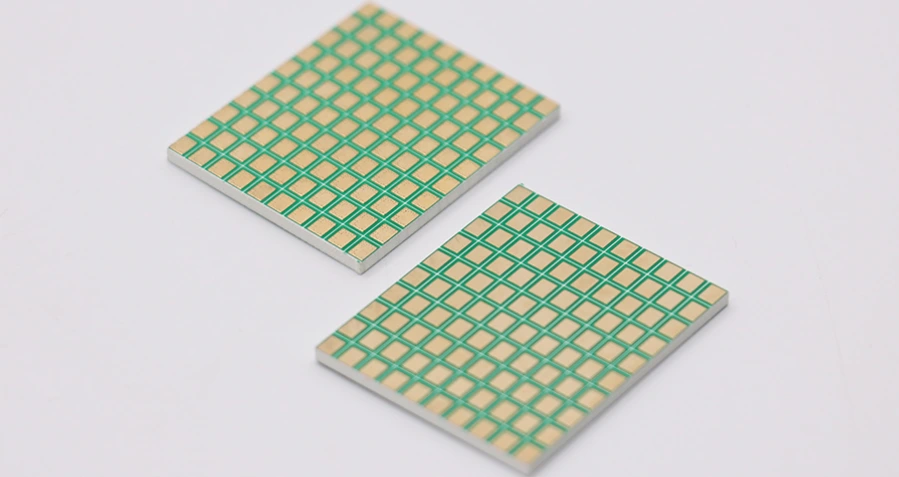

Highleap PCB Factory employs state-of-the-art equipment specifically optimized for epoxy PCB production. Our manufacturing facility processes over 50,000 square meters of epoxy circuit boards monthly, ranging from simple single and double layer designs to complex HDI structures with microvias and sequential lamination. Standard capabilities include 2-40 layer epoxy PCBs with minimum trace/space of 2/2 mils, via sizes down to 0.1mm, and board thicknesses from 0.2mm to 8.0mm.

The epoxy PCB fabrication process begins with precision cutting and drilling using high-speed CNC machines calibrated for epoxy resin materials. Our controlled drilling parameters prevent delamination and ensure clean hole walls essential for reliable plated through-holes. Surface preparation utilizes automated scrubbing and micro-etching to optimize copper adhesion, followed by pattern plating processes that build precise conductor geometries. Advanced AOI systems inspect every panel at critical stages, maintaining defect rates below 100 PPM.

For specialized requirements, we offer heavy copper epoxy PCBs up to 10 oz, impedance-controlled designs with ±5% tolerance, and blind/buried via technology for high-density interconnects. Our quick-turn epoxy PCB service delivers prototypes in 24-48 hours for standard 2-layer boards, with expedited options available for multilayer designs. Volume production leverages optimized panel utilization and parallel processing lines to achieve competitive pricing without compromising quality.

Epoxy PCB Assembly and Complete Solutions

Beyond bare board fabrication, HILPCB provides comprehensive epoxy PCB assembly services utilizing modern SMT assembly lines with 0201 component capability and ±25 micron placement accuracy. Our assembly facility handles both prototype quantities and volume production, with dedicated lines for high-mix/low-volume and low-mix/high-volume requirements. Automated optical inspection, in-circuit testing, and functional validation ensure assembled epoxy circuit boards meet all performance specifications.

We manage complete supply chain requirements including component sourcing, inventory management, and box-build integration. Our engineering support includes DFM analysis, test fixture development, and programming services. Whether you need turnkey assembly manufacturing or consigned assembly, our flexible engagement models adapt to your specific needs while maintaining consistent quality standards.

Quality Assurance and Certifications

Every epoxy PCB manufactured at HILPCB undergoes rigorous quality control exceeding IPC-6012 Class 2 standards, with Class 3 available for high-reliability applications. Our quality management system maintains ISO 9001:2015, IATF 16949, and UL certifications, demonstrating commitment to continuous improvement and customer satisfaction. Comprehensive testing includes electrical verification, microsection analysis, ionic cleanliness testing, and thermal stress screening.

We provide detailed quality documentation including material certificates, test reports, and first article inspection data. Our customer portal offers real-time access to order status, quality metrics, and shipment tracking. With over 15 years of experience in epoxy PCB manufacturing, we've developed robust processes that consistently deliver defect-free products to customers worldwide.

Global Logistics and Customer Support

HILPCB streamlines international shipping through partnerships with DHL, FedEx, and UPS, ensuring rapid delivery of epoxy PCBs to any global destination. Our export team handles all documentation requirements including commercial invoices, certificates of origin, and customs declarations. Temperature-controlled packaging protects moisture-sensitive assemblies during transit.

Payment flexibility includes wire transfer, PayPal, and major credit cards, with NET terms available for qualified accounts. Our multilingual customer service team provides 24/7 support via email, phone, and instant messaging. Technical queries receive prompt responses from experienced engineers who understand the nuances of epoxy PCB design and manufacturing.

Why Choose HILPCB for Epoxy PCB Manufacturing

Selecting the right epoxy PCB manufacturer impacts product quality, development timelines, and total cost of ownership. HILPCB combines technical expertise with customer-focused service to deliver superior value. Our advantages include:

- Rapid Prototyping: 24-hour quick-turn for standard epoxy PCBs

- Scalable Production: Seamless transition from prototype to volume manufacturing

- Technical Support: Free DFM review and stack-up recommendations

- Quality Guarantee: Zero-defect commitment with comprehensive warranty

- Competitive Pricing: Direct factory pricing with no hidden fees

- One-Stop Solution: Complete manufacturing and assembly services

Partner with HILPCB for your next epoxy PCB project and experience the difference of working with a dedicated manufacturer committed to your success. Request a quote today and let our team demonstrate how we can accelerate your product development while ensuring exceptional quality and reliability.

FAQ

What is the typical lead time for epoxy PCB manufacturing?

Standard 2-4 layer epoxy PCBs ship in 5-7 business days, with 24-48 hour expedite options available. Complex multilayer boards typically require 10-15 days depending on specifications. We maintain material inventory for common epoxy laminates to minimize procurement delays.

Can you manufacture both rigid and flexible epoxy PCBs?

While epoxy resins are primarily used for rigid PCBs, we also manufacture rigid-flex designs combining epoxy-based rigid sections with polyimide flexible circuits. Our engineering team can advise on optimal material selection for your specific application requirements.

What file formats do you accept for epoxy PCB orders?

We accept industry-standard Gerber files (RS-274X), Excellon drill files, and pick-and-place data for assembly. Our CAM team also works with native CAD formats including Altium, Eagle, KiCad, and others. Free file review ensures manufacturability before production begins.

Do you offer impedance control for high-speed epoxy PCBs?

Yes, we provide controlled impedance manufacturing with ±10% standard tolerance (±5% available). Our pre-production modeling ensures accurate impedance values, with TDR testing to verify performance. We support various controlled impedance structures including microstrip, stripline, and differential pairs.

What certifications do your epoxy PCBs meet?

All epoxy PCBs are manufactured to IPC standards and are RoHS/REACH compliant. We maintain UL recognition (E484959) for various epoxy laminates. Additional certifications include ISO 9001:2015, IATF 16949 for automotive, and AS9100D for aerospace applications.

Can you source components for epoxy PCB assembly?

Yes, we offer full turnkey assembly services including component sourcing from authorized distributors. Our procurement team ensures authentic parts with full traceability. We also provide consignment assembly options if you prefer to supply components directly.