HILPCB is a full-service PCB manufacturer and assembler providing complete solutions across rigid, flex, and rigid-flex PCB manufacturing. With advanced fabrication lines, precision SMT assembly, and strict quality control, we support everything from rapid prototypes to high-volume production for global OEMs and design engineers.

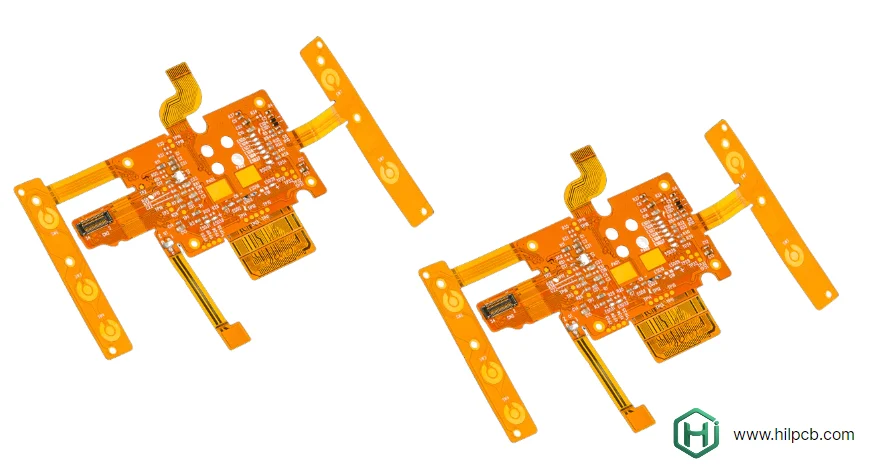

Our flex PCB manufacturing capability is part of a broader production system designed for performance-critical electronics — combining flexible circuit fabrication, component assembly, and end-to-end testing under one ISO- and IATF-certified process. This allows customers to reduce lead times, improve design consistency, and scale production efficiently without switching suppliers.

Whether your project involves standard FR4, high-density HDI, or hybrid rigid-flex builds, HILPCB delivers precise engineering, reliable performance, and cost-effective manufacturing — all from a single, trusted source.

1. Core Capabilities in Flex PCB Manufacturing

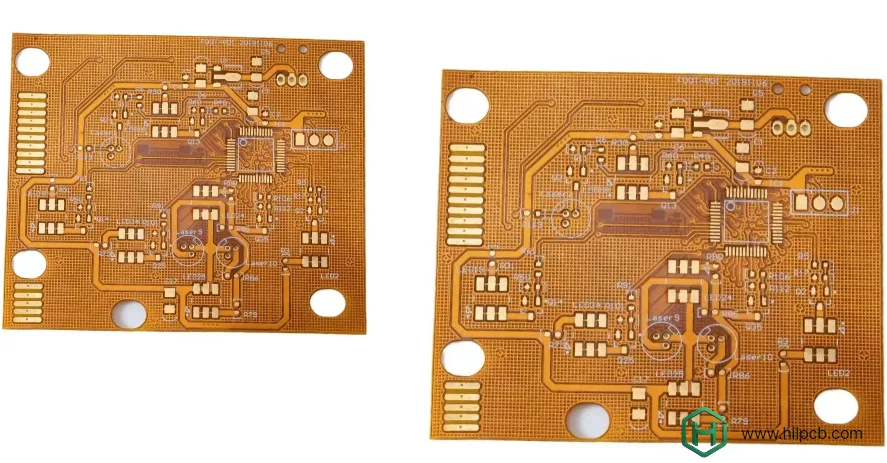

Professional flex PCB manufacturing requires precise control over material properties, registration accuracy, and circuit geometry. At HILPCB, our capabilities cover both standard and advanced flex PCB types:

- Single, double, and multilayer flex PCB fabrication

- Trace/space down to 0.075 mm (3 mil) and laser microvias to 0.10 mm

- Polyimide and adhesiveless laminates for high-flex endurance

- Copper thickness options from 0.5 oz to 2 oz

- Roll-to-roll and large-panel manufacturing up to 600 × 1200 mm

- Controlled impedance and EMI shielding for high-speed signal circuits

Our process capability ensures excellent yield, stable impedance control, and consistent quality for designs used in compact or high-reliability applications.

2. Materials and Process Technology

Material choice defines flexibility, durability, and cost. We use premium-grade polyimide substrates (DuPont Kapton, UPILEX, Panasonic Felios) for superior mechanical stability and heat resistance up to +400 °C. Polyester (PET) provides cost efficiency for light-duty consumer applications. For copper, rolled annealed (RA) foil is standard for dynamic flex, while electrodeposited (ED) suits static installations.

Manufacturing steps include:

- Laser direct imaging (LDI) for fine-line definition

- Controlled chemical etching minimizing undercutting

- Layer lamination under vacuum for multilayer flex circuits

- Laser drilling for blind/buried vias in HDI PCB designs

- Polyimide coverlay lamination for mechanical and chemical protection

- Surface finishes such as ENIG, immersion silver, and hard gold

Every process operates in temperature- and humidity-controlled environments to ensure repeatability and dimensional precision.

3. Quality Control and Reliability Assurance

High-quality flex PCB manufacturing relies on a strong quality framework. HILPCB implements international standards throughout production:

- Certifications: ISO 9001, ISO 13485 (medical), IATF 16949 (automotive), IPC-6013 (flex PCB specification)

- In-Process Control: statistical process control (SPC), registration accuracy monitoring, plating thickness tracking

- Testing: 100% AOI, flying-probe electrical test, impedance verification, peel-strength testing, thermal-shock and flex-cycle endurance

Each batch is traceable through digital process records and serialized documentation.

Our reliability testing replicates real-world stresses—vibration, temperature cycling, and humidity exposure—ensuring long-term performance across mission-critical environments.

4. Cost, Lead Time, and Prototyping Flexibility

Buyers selecting a flex PCB manufacturer often prioritize cost transparency, prototype speed, and scalability. HILPCB optimizes these through efficient production planning and one-stop fabrication + SMT assembly:

- Lead times:

- Single/dual-layer flex: 5 – 10 days

- Multilayer or rigid-flex: 12 – 18 days

- Quick-turn prototype: 3 – 5 days

- Pricing factors: substrate type, copper weight, layer count, and panel utilization

- Prototyping: low-volume runs validated before mass production

- Scalability: automated line transition from samples to high-volume production

By integrating fabrication, assembly, and testing in one certified facility, we reduce communication steps and shorten total project cycles by 20 – 30%.

5. Why Partner with HILPCB for Flex PCB Manufacturing

HILPCB stands among leading flex PCB manufacturers, combining engineering expertise, advanced process control, and global logistics support. We serve customers in consumer electronics, automotive, industrial, and aerospace sectors who demand performance consistency and responsive service.

Our advantages include:

- End-to-end flex PCB manufacturing and assembly under one roof

- Expert DFM support from layout review to stack-up optimization

- ISO- and IPC-certified quality systems

- Quick-turn prototyping and stable mass production

- Real-time communication and technical support in English & Mandarin

Partnering with HILPCB ensures not only manufacturing precision but also long-term reliability and supply stability—essential for today’s fast-moving electronic industries.

Frequently Asked Questions — Flex PCB Manufacturing

Q1: What is the typical lead time for flex PCB manufacturing?

A: Lead times vary by complexity: single layer flex PCB prototypes in 5-7 days; double layer flex PCB in 7-10 days; multilayer constructions 12-18 days. Production volumes typically add 5-10 days. Quick-turn services available with premium charges.

Q2: How does flex PCB manufacturing cost compare to rigid PCB?

A: Flex PCB costs 2-5x rigid PCB equivalent due to material costs (polyimide vs. FR-4), specialized processing, and lower manufacturing volumes. However, system-level costs may be lower when eliminating connectors, cables, and assembly labor.

Q3: What certifications does HILPCB maintain for flex PCB manufacturing?

A: We are ISO 9001:2015, IPC-A-610 Class 3, and IPC-6013 certified. Industry-specific certifications include ISO 13485 (medical), IATF 16949 (automotive), and AS9100 (aerospace). Our quality systems support customer-specific requirements.

Q4: Can you manufacture rigid-flex PCB combinations?

A: Yes, our rigid-flex PCB capabilities combine rigid sections (for component mounting) with flexible interconnects. This integrated approach eliminates connectors while providing mechanical stability where needed. Complexity ranges from simple 2-layer rigid + 1-layer flex up to complex multilayer combinations.

Q5: What design files do you need for flex PCB manufacturing?

A: We require Gerber files (RS-274X format), drill files (Excellon format), and fabrication drawings specifying materials, finishes, tolerances, and special requirements. ODB++ or IPC-2581 formats also accepted. Early design review recommended using our Gerber viewer tool before ordering.