Selecting a Flexible PCB manufacturer isn’t just about finding the lowest quote — it’s about choosing a partner who can meet your design intent, production volume, and reliability requirements without compromise. In high-performance electronics, every flex circuit must deliver precise electrical integrity, consistent quality, and predictable lead time.

At HILPCB, we understand that your success depends on dependable manufacturing. Our flexible PCB production systems combine precision process control, advanced materials, and ISO-certified quality management to ensure stable performance from prototype to mass production.

Evaluating Flexible PCB Manufacturing Capabilities

Process and Technology Capability

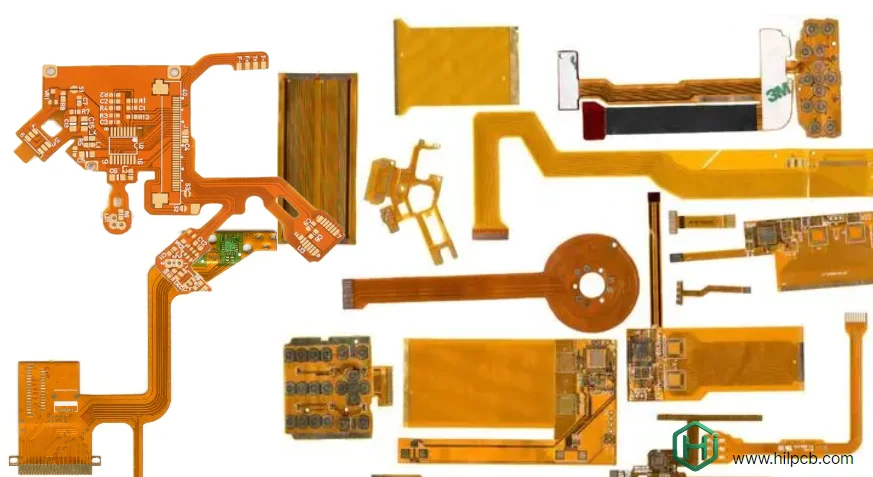

A reliable Flexible PCB manufacturer should demonstrate precision, scalability, and versatility across multiple fabrication formats. Key evaluation areas include:

- Minimum trace width and spacing — standard 100 μm (4 mil); advanced 75 μm (3 mil) for fine-pitch interconnects.

- Via and microvia capability — mechanical drilling down to 200 μm; laser microvias as small as 100 μm for HDI stack-ups.

- Layer count range — from single-layer flex to 16-layer multilayer and rigid-flex PCB manufacturing, enabling compact, high-density packaging.

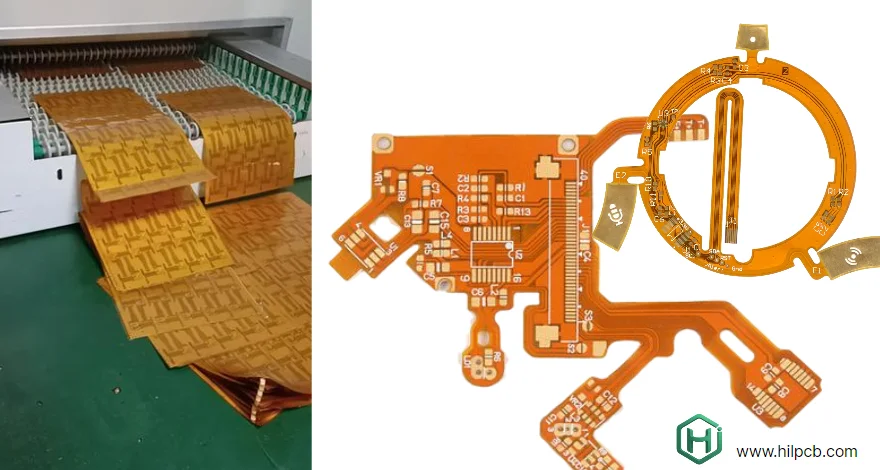

- Large-format flexible PCB manufacturing — panel sizes up to 600 × 1200 mm or custom configurations for industrial sensors, displays, and control systems.

- Extra-long flexible PCB manufacturing — roll-to-roll production extending to tens of meters or more, ideal for LED modules, sensor arrays, and wearable electronics.

- Controlled impedance and EMI shielding design capabilities for high-speed signal integrity.

- Flexible PCB assembly (FPC Assembly) support — surface-mount, chip-on-flex (COF), and fine-pitch connector integration for complete turnkey solutions.

Modern manufacturers employ Direct Laser Imaging (DLI), Automated Optical Inspection (AOI), and Statistical Process Control (SPC) to maintain consistent yields. Ensure the facility supports adhesiveless polyimide, RA copper, and multi-type assembly lines capable of handling both standard and high-temperature flex materials.

Quality Systems and Reliability Assurance

Quality Certifications and Traceability

A manufacturer’s quality management system defines its ability to deliver consistent results.

Look for:

- ISO 9001 — baseline process and documentation control

- ISO 13485 — medical device quality (traceability, biocompatibility, sterilization records)

- IATF 16949 — automotive manufacturing discipline (PPAP, FMEA, APQP)

- AS9100 — aerospace-level quality assurance

Certified facilities should also follow IPC-6013 and IPC-A-600 workmanship standards, backed by flexible PCB manufacturing quality systems and full traceability.

Testing and Inspection Capabilities

Ask if the manufacturer provides:

- 100% electrical testing (continuity and isolation)

- Microsection analysis to confirm plating and layer bonding quality

- Flex-cycle and thermal cycling tests to simulate real-world fatigue

- Dimensional inspection for bend radius and stack-up accuracy

Reliable manufacturers record these metrics digitally for traceability, ensuring each batch meets your application’s durability requirements.

Business and Partnership Evaluation

Communication and Engineering Support

Effective communication defines the strength of your partnership. A trustworthy Flexible PCB manufacturer provides quick, technical responses, not just price quotes.

Look for:

- Design-for-manufacturability reviews during quoting

- Direct access to engineering staff for design optimization

- Real-time order tracking and clear project timelines

Lead Time and Production Capacity

Prototype lead times typically range from 5–7 days, while standard production cycles run 10–15 days. Manufacturers offering both quick-turn and mass production capabilities streamline transition from R&D to market.

Ask whether they can scale efficiently from prototypes to volume without altering material specs or processes — this consistency is critical for quality-sensitive applications like automotive or aerospace.

Pricing Transparency and Total Cost

Don’t compare manufacturers by price alone. Evaluate total cost, including:

- Tooling/setup fees

- Yield performance and rework rates

- Material premiums such as polyimide PCB materials or RA copper

- Logistics, customs, and time-to-market impact

A slightly higher unit cost from a reliable partner can save thousands in reduced field failures and faster delivery.

HILPCB — Your Trusted Flexible PCB Manufacturer

At HILPCB, we combine engineering depth with scalable production to deliver reliable flexible PCB manufacturing for demanding applications worldwide.

Technical Expertise

- 1–16 layer flex and rigid-flex PCBs with 75 μm line width and 100 μm microvias

- Adhesiveless and polyimide film systems rated up to +250 °C

- HDI flexible PCB manufacturing and impedance-controlled stack-ups for high-speed circuits

Quality Commitment

- Certified under ISO 9001, ISO 13485, and IATF 16949

- 100% AOI + E-test coverage and reliability validation

- SPC monitoring, flex-cycle, and thermal shock testing for each batch

Customer Partnership

- Engineering support with DFM guidance before production

- Rapid prototype turnaround and scalable volume manufacturing

- Vertical integration from raw materials to SMT assembly and box build

From consumer electronics to aerospace modules, HILPCB ensures your flexible circuits perform reliably and scale efficiently — backed by data, certification, and real manufacturing expertise.

Frequently Asked Questions

Q1: What certifications should a flexible PCB manufacturer have?

At minimum, ISO 9001 is essential. For medical or automotive sectors, require ISO 13485 or IATF 16949. Aerospace programs typically demand AS9100 or MIL-PRF.

Q2: How can I verify a supplier’s true capability?

Ask for process capability data (Cpk), sample boards, and factory audit reports. Reliable manufacturers provide cross-sections, DFM feedback, and statistical quality results.

Q3: What are realistic lead times for flex PCB production?

5–7 days for prototypes, 10–15 days for production. Complex rigid-flex may require 15–20 days depending on layer count and materials.

Q4: Is manufacturer location important?

Yes. Local suppliers offer faster prototyping and communication. Asian partners often excel in high-volume cost efficiency. Balance speed and scale based on your priority.

Q5: What’s the best sourcing strategy for flex PCBs?

Use a hybrid approach — prototype with a local partner for speed, then transfer volume to a qualified offshore manufacturer for cost efficiency.