Manufacturing flexible PCBs demands specialized processes, equipment, and expertise beyond rigid board production. Thin, delicate materials require gentle handling while maintaining precise tolerances. Understanding manufacturing processes helps engineers design manufacturable products and select capable suppliers.

HILPCB's flexible PCB manufacturing facility employs advanced equipment and process controls delivering consistent quality from prototype through production. Our vertical integration ensures control over every manufacturing step.

Understanding Flexible PCB Manufacturing Costs

Flexible PCB pricing is determined by a combination of material, layer count, copper thickness, and complexity. Understanding how each factor contributes helps you optimize your design for manufacturability.

1. Material and Film Type

- Polyimide vs. PET: polyimide offers superior temperature resistance but costs more.

- Adhesiveless vs. adhesive-based: adhesiveless constructions are thinner and more reliable for HDI but add ~15–25% to material cost.

2. Layer Count and Copper Weight

- Each additional layer increases cost ~20–30% due to added lamination cycles.

- Copper thickness impacts flexibility and price; 1 oz is standard, 2 oz used for power circuits.

3. Design Complexity

- Fine-pitch traces (<3 mil), microvias, and impedance-controlled routing increase both setup time and yield risk.

- Tight bend radii may require RA copper and special processing, adding 5–10% to cost.

4. Order Volume and Turnaround

- Prototypes and small batches have higher per-unit cost due to setup overhead.

- High-volume production allows process optimization and price scaling.

Material Preparation and Inspection

Quality flex circuits begin with verified materials. Incoming inspection confirms specifications before processing, preventing defects originating from substandard materials.

Substrate Verification Polyimide film arrives in rolls requiring thickness measurement, visual inspection, and dielectric testing. Micrometer measurements verify thickness uniformity across width and length. Surface inspection identifies defects including scratches, particulate contamination, or adhesive voids. Dielectric testing confirms electrical properties match specifications.

Copper-clad laminates undergo additional verification. Copper thickness measurement using X-ray fluorescence confirms weight specification (½ oz, 1 oz, 2 oz). Peel strength testing validates copper-to-substrate adhesion. Dimensional stability testing under thermal cycling predicts performance during processing and application.

Material Storage and Handling Environmental control prevents moisture absorption and contamination. Storage at 20-25°C and 40-60% relative humidity minimizes dimensional changes. Material handling procedures prevent mechanical damage to thin films. Automated material transport systems reduce handling while maintaining traceability.

Material traceability systems track lot numbers from receipt through finished products. This enables root cause analysis if quality issues arise and supports medical device quality systems requiring complete material genealogy.

Imaging and Pattern Transfer

Creating circuit patterns on flexible substrates requires precision photolithography adapted to material properties.

Photoresist Application Liquid photoresist coating or dry film lamination creates light-sensitive layer over copper. Coating thickness control ensures consistent exposure and development. Automated application systems maintain uniform coverage despite material flexibility. Soft baking drives out solvents, hardening resist for exposure.

High-Resolution Exposure UV exposure through phototool creates latent image in photoresist. Direct laser imaging (DLI) systems eliminate phototools, enabling rapid design changes and fine-pitch capabilities. Exposure energy control ensures complete polymerization in exposed areas while preventing under-cut in masked regions.

Flexible material flatness during exposure affects image quality. Vacuum contact exposure presses film against phototool ensuring intimate contact. Registration pins align double-sided designs maintaining ±0.05mm accuracy between sides.

Development and Etching Chemical development removes unexposed photoresist, revealing copper for etching. Spray development systems provide uniform processing without mechanical damage. Inspection confirms pattern transfer before etching.

Controlled chemical etching removes exposed copper forming circuit pattern. Spray etching maintains consistent etch rate across panel. Process monitoring adjusts chemistry concentration and temperature compensating for copper loading. Proper etching preserves copper ductility essential for flexibility while maintaining precise line width.

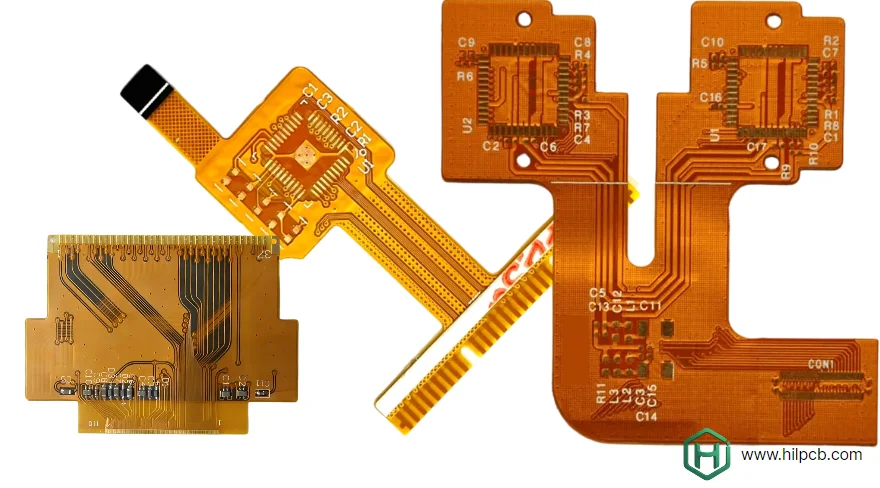

Lamination and Multilayer Construction

Multilayer flexible PCBs require sophisticated lamination processes bonding individual layers into integrated assemblies.

Layer Alignment Automated optical systems align inner layers with ±0.075mm accuracy. Fiducial marks enable machine vision recognition and positioning. Compensation for material expansion during processing maintains accuracy across temperature variations.

Pin lamination presses use tooling holes maintaining alignment through lamination cycle. Pressure-sensitive adhesive (PSA) pre-bonds layers before final lamination preventing shifting. Registration verification before lamination prevents scrapping expensive assemblies.

Lamination Process Control Vacuum lamination presses apply heat and pressure bonding layers together. Process parameters including temperature, pressure, and time require precise control. Typical cycles run 30-120 minutes at 150-180°C and 3-5 bar pressure depending on adhesive system.

Temperature profiling ensures uniform heating across panel preventing hot spots or cold zones causing inadequate bonding. Vacuum evacuation removes entrapped air preventing voids in dielectric regions affecting electrical performance.

Via Formation Drilling creates connections between layers in multilayer construction. High-speed spindles (60,000-100,000 rpm) with specialty bits drill thin materials cleanly. CNC control positions holes with ±0.05mm accuracy. Stack drilling maintains hole quality through multiple layers despite differing materials.

Laser drilling enables smaller vias (100μm diameter) impossible with mechanical drilling. CO2 or UV lasers ablate polyimide creating via holes. Controlled energy prevents excessive carbonization ensuring reliable plating. Desmear treatment removes polyimide residue before electroplating.

Copper Plating Electroless copper deposition initiates conductive layer inside via holes. Electrolytic plating builds copper thickness connecting layers electrically. Plating uniformity affects via reliability—thin plating causes high resistance, thick plating creates brittle connections.

Process control maintains plating thickness within ±10% across panel. Agitation, current density, and chemistry control ensure consistent results. Post-plating cross-sections verify plating quality and via-fill completion.

HILPCB — Trusted Partner for Flexible PCB Manufacturing

At HILPCB, we deliver end-to-end Flexible PCB manufacturing solutions that meet the demands of diverse industries — from compact consumer wearables to aerospace-grade flex assemblies. Our engineering team combines precision process control, global material sourcing, and ISO-certified production systems to ensure performance, consistency, and scalability.

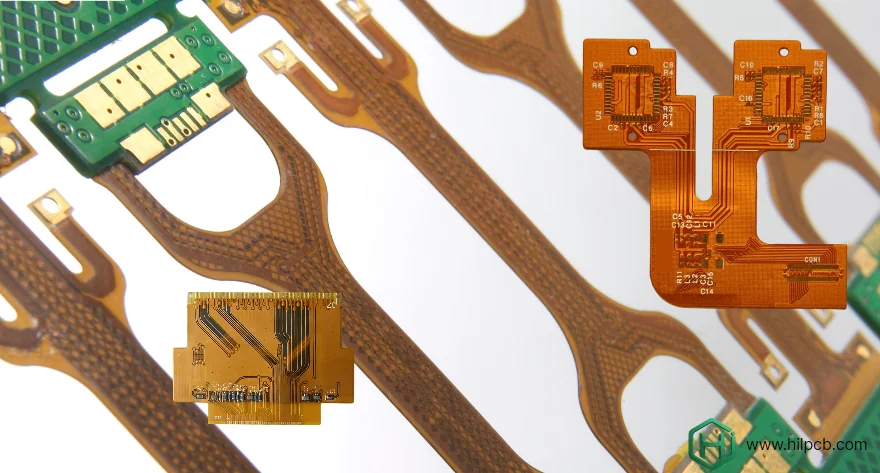

Our manufacturing capabilities cover the full spectrum of flexible circuit technologies:

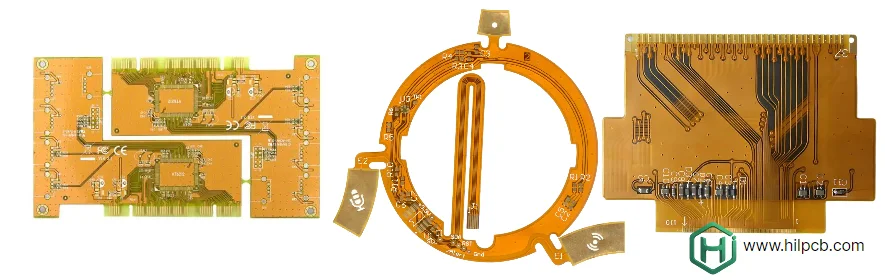

- Single- and Multilayer Flexible PCB Manufacturing – From 1 to 16 layers (and beyond on request), with RA or ED copper, adhesiveless or adhesive-based constructions, and options for controlled impedance and EMI shielding. Ideal for high-density interconnect (HDI) applications and high-speed signal routing.

- Rigid-Flex and Stiffener Integration – Polyimide, FR4, stainless steel or aluminum stiffeners provide mechanical reinforcement for connector and component zones. HILPCB designs optimized stiffener transitions that maintain bending reliability while enabling ZIF, FPC-to-PCB, or board-to-board connections.

- Ultra-Long Flexible PCB (Roll-to-Roll Production) – Capable of continuous length FPCs extending for tens of metres and more, using roll-to-roll manufacturing. This suits LED strips, sensor arrays, automotive lighting harnesses and other long-layout applications. (Roll-to-roll techniques are recognized for enabling “several metres long” flex circuits via continuous production.)

- Large-Format Flexible PCB Manufacturing – Oversized panel capability (e.g., up to approx. 600 × 1200 mm or larger) delivers stable registration for industrial sensors, large displays, medical devices and rigid-flex systems with extended dimensions.

- High-Temperature and Chemical-Resistant Flex Circuits – Polyimide films, adhesiveless constructions, and special coatings for applications exceeding +250 °C or exposed to solvents, fuels, and cleaning agents.

- Quick-Turn Prototyping through Scalable Production – From R&D prototypes to millions of units annually, with consistent specifications, Statistical Process Control (SPC), and 100 % AOI and E-test coverage.

Quality assurance underpins every stage of production. SPC analytics monitor key process parameters in real time, while flex-cycle testing, thermal-shock evaluation, and microsection analysis validate long-term reliability. Our ISO 9001, ISO 13485 and IATF 16949 certifications guarantee compliance across consumer, automotive, medical and aerospace markets.

Whether your project requires ultra-thin flexible interconnects, complex multilayer rigid-flex assemblies, extra-long continuous flex circuits or large-format panel builds, HILPCB provides the engineering insight, manufacturing precision and global logistics support to bring your designs to market faster and perform reliably in the field.

Frequently Asked Questions

Q1: What makes flexible PCB manufacturing different from rigid PCB production?

Flexible materials require specialized handling and vacuum systems instead of mechanical clamps. Processing parameters are tailored to polyimide substrates rather than FR4, ensuring precision and flexibility through each production stage.

Q2: How long does flexible PCB manufacturing take?

Standard prototypes typically ship within 5–7 days. Single-sided designs may finish in 3–5 days, while multilayer flex builds take 7–10 days. Full production runs require 10–15 days depending on complexity.

Q3: What certifications does HILPCB maintain for flexible PCB manufacturing?

Our facility holds ISO 9001, ISO 13485, and IATF 16949 certifications, with UL and AS9100 compliance for aerospace and defense projects.

Q4: Can you produce fine-pitch flexible PCBs with small vias?

Yes. Our HDI processes achieve 75 μm (3 mil) lines and spaces with laser-drilled 100 μm microvias, supporting advanced interconnect density for compact devices.

Q5: How do you ensure consistent quality across production batches?

SPC monitoring, AOI inspection, and lot-level traceability maintain quality uniformity. Real-time data analysis enables immediate process correction, ensuring consistent results across all builds.