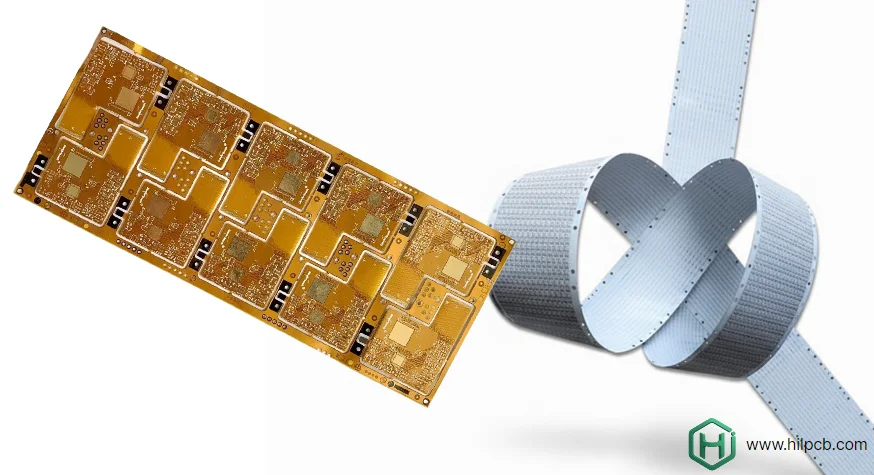

HILPCB is a full-service electronics manufacturer providing complete solutions—from PCB fabrication to component sourcing, assembly, and turnkey electronic manufacturing services. We specialize in all PCB types including rigid, flex, and rigid-flex constructions, delivering precision and reliability for consumer, industrial, automotive, and medical electronics.

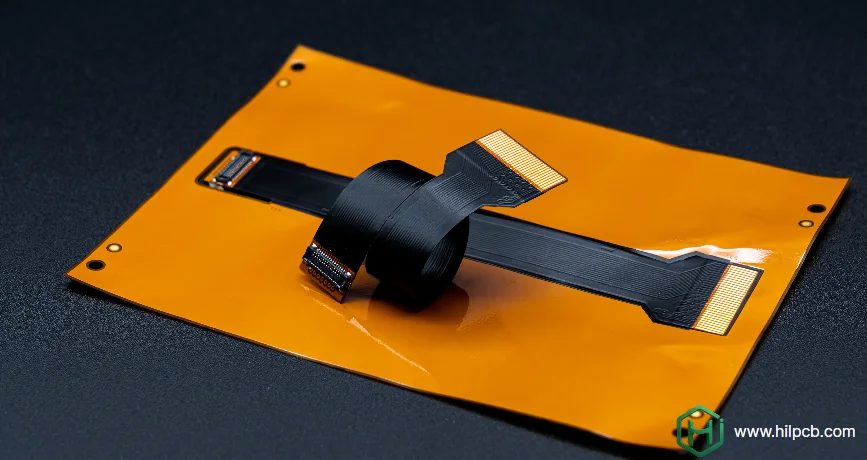

Among these, FPC (Flexible Printed Circuit) boards have redefined how engineers design compact, lightweight, and high-performance products. Once exclusive to aerospace, FPC technology now powers innovation across smartphones, medical implants, electric vehicles, and advanced industrial systems. Understanding where and how FPCs are applied helps engineers and product teams unlock their full design potential

FPC Board Applications Across Industries

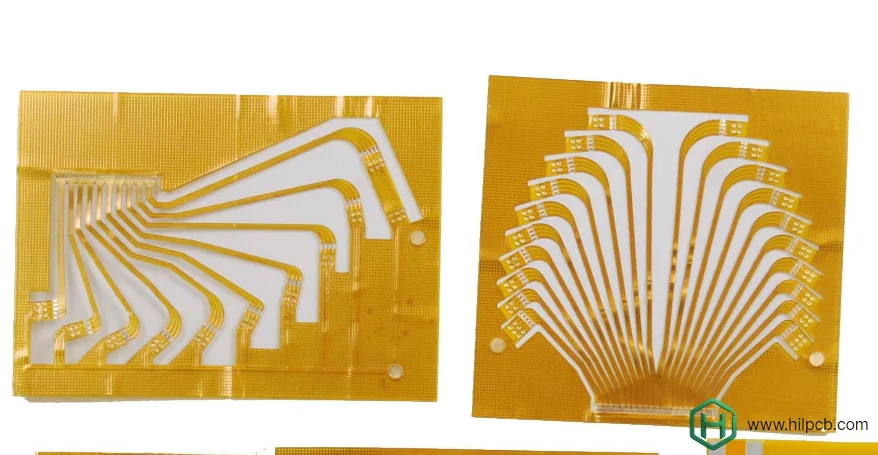

Flex PCB technology has become essential in modern electronics manufacturing. Its ability to support compact, lightweight, and reliable connections makes it widely adopted across consumer, automotive, medical, industrial, aerospace, and communication sectors. The following outlines major application areas in each industry.

Consumer Electronics Smartphones, tablets, laptops, smartwatches, fitness trackers, foldable and rollable displays, wireless charging modules, Bluetooth earphones, VR and AR headsets, portable gaming consoles, digital cameras, e-readers, and smart home controllers.

Automotive Electronics Instrument clusters, steering wheel controls, airbag sensors, seat occupancy systems, rearview cameras, infotainment touchscreens, engine control modules, LED lighting systems, EV battery management, radar and LiDAR sensors, HVAC control units, smart mirrors, and interior ambient lighting.

Medical and Healthcare Wearable health monitors, implantable devices, portable diagnostics, hearing aids, endoscopic cameras, glucose monitors, ECG and EEG patches, medical imaging systems, drug delivery devices, and disposable biosensors.

Industrial and Robotics Automation controllers, sensor arrays, motor drivers, robotic arm interconnects, LED lighting controls, barcode scanners, factory monitoring sensors, flexible HMI displays, power monitoring systems, and energy storage sensors.

Aerospace and Defense Avionics displays, satellite modules, navigation and radar systems, flight control electronics, space sensors, UAV wiring systems, cockpit panels, military communications, missile guidance circuits, and environmental instrumentation.

Telecommunications and Networking Antenna connectors, 5G base stations, optical transceiver modules, RF routing assemblies, network switches, data interface circuits, IoT node interconnects, routers, and modems.

Medical Device FPC Solutions

Medical applications demand highest reliability with biocompatibility and sterilization resistance. FPC boards enable minimally invasive procedures and implantable devices improving patient outcomes.

Surgical Instrument Electronics Endoscopic cameras and robotic surgical tools incorporate flexible PCBs within small-diameter shafts. Multi-layer FPC integrates illumination LEDs, image sensors, and control circuitry. Repeated sterilization cycles (autoclave, EtO, gamma radiation) require material qualification and testing.

Implantable Medical Devices Cardiac pacemakers and neurostimulators use FPC boards connecting battery packs to control electronics. Hermetic sealing protects circuits from body fluids for 10+ year service life. Biocompatible materials pass ISO 10993 testing for long-term tissue contact. Ultra-reliable manufacturing processes eliminate defects that could cause device failure.

Wearable Health Monitors Continuous glucose monitors and cardiac patches attach directly to skin. FPC boards integrate sensors, wireless communication, and power management in thin, comfortable packages. Stretchable designs accommodate body movement. Adhesive-compatible materials enable secure attachment without skin irritation.

Diagnostic Equipment Ultrasound probes contain sophisticated FPC boards connecting transducer arrays to processing electronics. High-density interconnects support thousands of individual elements. Shielded flex constructions minimize electromagnetic interference in sensitive analog signals.

Automotive FPC Board Integration

Vehicles increasingly rely on FPC boards for reliable connections in harsh environments. Temperature extremes, vibration, and chemical exposure challenge standard interconnects.

Dashboard and Instrument Clusters Modern digital dashboards use FPC assemblies connecting display panels to control modules. Curved displays require flexible connections accommodating 3D shapes. Automotive-grade materials withstand temperature cycling from -40°C to +85°C. LED backlighting integrates directly on FPC reducing component count.

Camera and Sensor Modules Advanced driver assistance systems (ADAS) deploy multiple cameras requiring reliable FPC connections. Flexible circuits route high-speed data while accommodating vehicle vibration. Environmental sealing protects against moisture and contamination. Automotive qualification testing validates long-term reliability.

Seat and Interior Electronics Heated seats, position sensors, and occupant detection systems use FPC for flexible connections accommodating seat movement. Thin profile minimizes interference with comfort padding. Flame-retardant materials meet automotive safety standards.

Electric Vehicle Battery Systems High-voltage battery packs rely on FPC boards for cell monitoring and thermal management. Flexible circuits conform to cylindrical cell geometries. High-current copper layers handle charging and discharge loads. Insulation systems prevent short circuits in high-voltage environments.

HILPCB — FPC Board Manufacturing Excellence

HILPCB’s FPC board capabilities serve diverse industries with complete solutions from concept to mass production. Our advanced manufacturing facility delivers flexible circuits with precision control, stable quality, and scalability—from single prototypes to millions of units annually. Streamlined production workflows ensure fast turnaround for consumer electronics, strict traceability for medical devices, and environmental validation for automotive applications.

Our engineering team provides comprehensive design and material support including stack-up optimization, impedance control, and manufacturability analysis. Early-stage DFM reviews prevent costly redesigns, while tailored material recommendations balance performance, flexibility, and cost. Application-specific testing protocols—such as flex-cycle endurance, temperature cycling, and reliability validation—guarantee long-term stability under real-world stress.

Quality management adapts to each market’s standards. Consumer products undergo electrical and visual inspection, medical FPCs include biocompatibility and material certifications, and automotive boards meet PPAP and stress-testing requirements. Combined with efficient assembly integration and supply chain coordination, HILPCB provides a fully scalable, one-stop solution for high-performance flexible circuits.

Frequently Asked Questions

Q1: What industries use FPC boards most commonly? Consumer electronics leads FPC adoption for smartphones, tablets, and wearables. Medical devices use FPC for implants and surgical instruments. Automotive applications include displays, cameras, and sensors. Aerospace, industrial automation, and IoT devices increasingly adopt FPC technology.

Q2: How do FPC boards improve product design compared to rigid PCBs? FPC boards enable 3D packaging, eliminating connectors and reducing weight 40-60%. Flexible circuits conform to product shapes, maximizing space utilization. Fewer interconnects improve reliability by reducing failure points. Dynamic flexing capabilities suit applications with moving parts.

Q3: What are typical lead times for FPC board manufacturing? Prototype FPC boards typically ship within 5-7 days for standard constructions. Production quantities require 10-15 days depending on complexity and volume. Specialized materials or unusual specifications may extend lead times. Expedited services available for urgent requirements.

Q4: Can FPC boards handle high-frequency RF signals? Yes, properly designed FPC boards support RF applications through controlled impedance construction. Coplanar waveguide and microstrip transmission lines maintain consistent impedance. Low-loss polyimide substrates minimize signal attenuation. Ground planes provide shielding for sensitive signals.

Q5: How are FPC boards tested for reliability? Standard testing includes electrical continuity and isolation verification. Flex-cycle testing validates mechanical reliability through repeated bending. Thermal cycling ensures performance across temperature range. Application-specific tests may include vibration, humidity, chemical resistance, or sterilization validation.