Your first FR4 prototypes passed testing perfectly. Small runs came back on time, and performance looked great. But when the volume increases, problems appear — yield drops, delays grow, and quality varies between batches.

That’s where the difference between a PCB supplier and a true manufacturing partner shows. At HILPCB, we help hardware teams and engineers move smoothly from sample to mass production — keeping FR4 PCB quality, yield, and delivery consistent at every scale.

1. What Buyers Should Look for in FR4 PCB Manufacturing

When you’re choosing a PCB manufacturer, the quote alone doesn’t tell the full story. The real difference lies in how the factory manages consistency — from material sourcing to final inspection.

Here’s what to check before you commit:

- Material traceability: can the supplier track every FR4 batch used in your boards?

- Process control: are fabrication parameters monitored automatically to prevent drift?

- Testing coverage: do they perform 100% electrical and optical inspections?

- Capacity buffer: can they handle urgent orders without affecting quality?

At HILPCB, every production lot is documented, traceable, and verified through our digital PCB manufacturing system. You get complete visibility — from FR4 laminate batches to inspection data — ensuring the same reliability across every shipment.

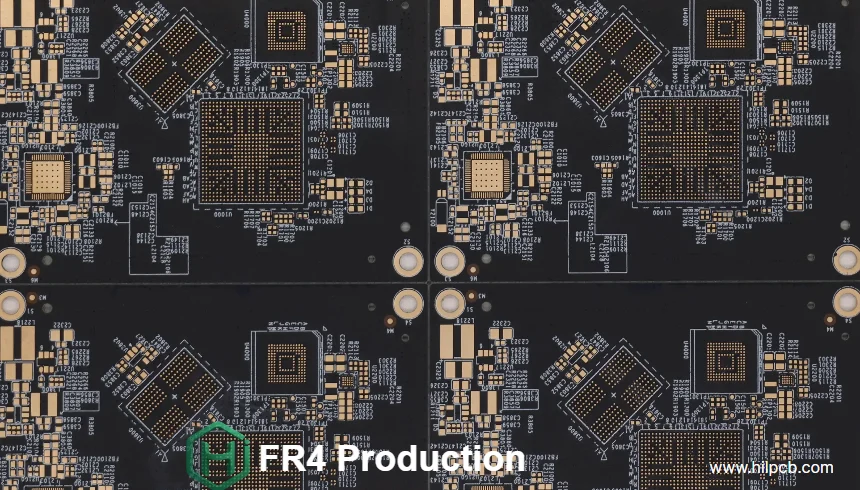

2. How HILPCB Keeps FR4 Quality Stable in Volume Production

Many PCB suppliers can produce good prototypes — but keeping that quality consistent at high volume is another story. At HILPCB, we focus on stability through control, ensuring every FR4 PCB performs the same no matter the batch size.

Controlled FR4 Material Qualification

We use only certified FR4 materials from trusted suppliers, carefully matching dielectric constant, resin content, and glass weave type. Each laminate lot is logged upon arrival, moisture-tested, and stored under controlled humidity. This prevents lot-to-lot variation — a common source of yield instability when scaling up. See our available FR4 substrate options.

Process Monitoring and Automated Inspection

Every production line integrates real-time measurement systems. Layer registration alignment is continuously tracked during lamination and drilling. Copper plating thickness is checked in-line for uniform deposition. Etching and trace width are verified against design tolerance by automated optical inspection (AOI). Impedance coupons are tested on every production lot for high-speed designs.

If any metric trends toward its limit, the system automatically flags and isolates the lot for review. That means defects are stopped before boards reach final test, protecting your yield and schedule.

Capacity Management That Protects Quality

Most quality issues occur when factories run beyond 90% utilization. We maintain 15–20% reserved capacity across our lamination, imaging, and testing lines to prevent overload. This ensures our process windows remain stable — especially for large or complex builds like multilayer PCBs or HDI PCBs.

It’s not just about speed — it’s about predictable output that meets your volume demand without compromise.

Layer-to-Assembly Integration

Because fabrication and assembly are both in-house, feedback flows instantly between departments. If assembly detects solder mask misalignment or via quality variation, fabrication is adjusted before the next batch. This closed feedback loop keeps overall yield consistent and reduces lead time across all FR4 PCB builds. Explore our one-stop PCB assembly services.

Result: Stable Yields and Repeatable Performance

The result of these controls is stable, measurable consistency. Layer registration within ±25 μm across builds. Copper thickness deviation under ±10%. Average first-pass yield above 98.5% for high-volume FR4.

For you, that means no performance surprises, predictable delivery windows, and boards that behave exactly as your prototype did.

3. From Prototype to Mass Production — Smooth Transition Without Surprises

Scaling from a few boards to thousands shouldn’t mean requalifying everything. HILPCB uses a structured ramp-up process designed to eliminate unexpected delays or redesigns.

Pre-production DFM review: we check your design for manufacturability and propose small, production-safe optimizations. Pilot run verification: a small validation batch confirms electrical and mechanical reliability. Locked parameters: proven settings are fixed for all future lots to ensure identical output. Batch reports: you receive test data, inspection results, and production photos with every delivery.

This process helps you move confidently from prototype to mass production — without cost surprises or schedule slips.

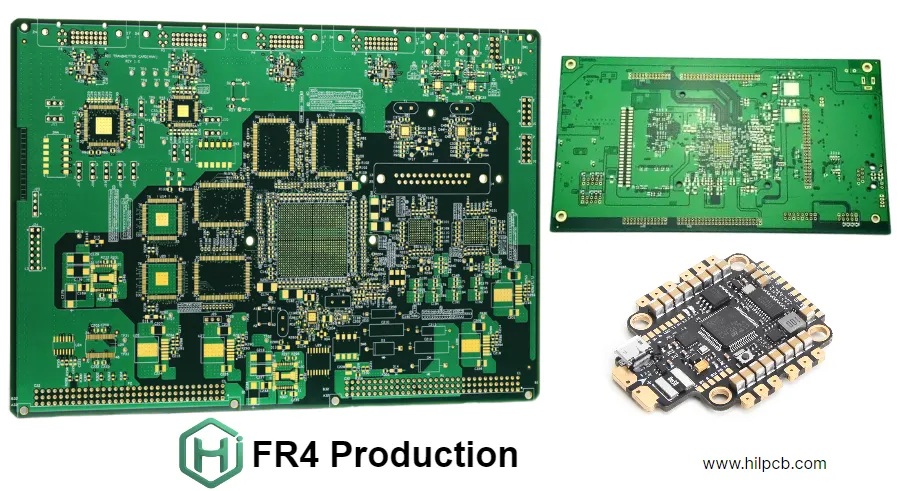

4. How HILPCB Ensures Reliable FR4 PCB Assembly

A great FR4 PCB is only half the journey — consistent assembly brings the design to life. Because fabrication and assembly happen under one roof at HILPCB, there’s no quality gap between stages.

Our assembly advantages include high-speed SMT and THT lines for fine-pitch and mixed-technology builds, automated optical (AOI) and X-ray inspection (AXI) for hidden defects, full functional testing for critical applications, and component traceability from sourcing to placement.

This integration eliminates vendor handoffs, shortens turnaround time, and guarantees consistent FR4 PCBA quality from start to finish. Learn more about our large-volume assembly capabilities.

5. Why Teams Choose HILPCB as Their Long-Term FR4 Partner

When you choose HILPCB, you’re not just buying boards — you’re gaining a partner who manages quality, time, and transparency at every stage.

Stable yields: proven results in rigid, flex, and HDI FR4 boards.

Predictable lead times: backed by capacity buffers and advanced scheduling.

Full traceability: digital records from laminate lot to final test.

One-stop service: from FR4 fabrication to assembly and testing — all under one roof.

Global support: fast communication, engineering feedback, and secure worldwide shipping.

Whether you’re building your first prototype or scaling full production, HILPCB delivers consistent FR4 PCB quality, dependable lead times, and complete manufacturing confidence.

FAQs

Do you offer both FR4 fabrication and assembly?

Yes — HILPCB provides complete PCB manufacturing, assembly, and testing in one facility for faster turnaround and guaranteed consistency.

Can you handle high-TG or multilayer FR4 boards?

Absolutely. We build high-TG FR4 and multilayer PCBs up to 32 layers, including HDI and fine-pitch designs.

How long does mass production take?

Standard FR4 production runs typically take 10–15 days, depending on complexity and volume. Express builds are available for urgent projects.

What if I need both prototype and volume runs?

We handle small-batch assembly and full-scale manufacturing using the same process, so you can scale confidently without changing suppliers.