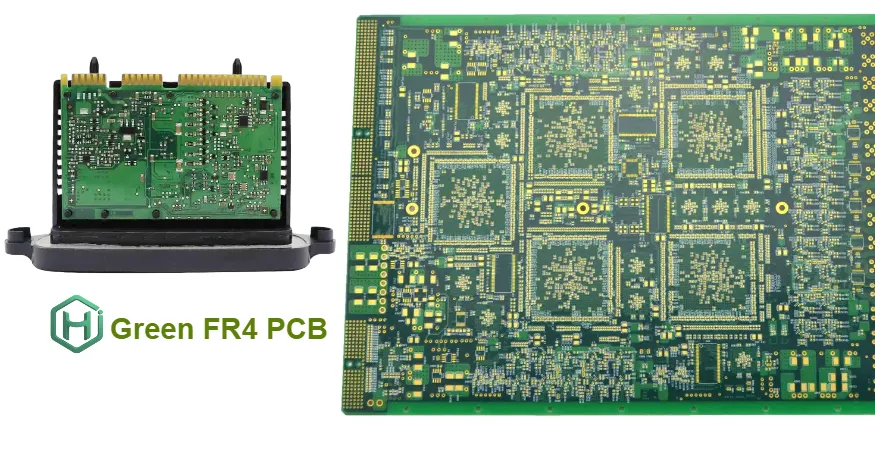

Green FR4 PCB remains the global industry standard, combining proven reliability, process stability, and environmental compliance. Its distinctive green solder mask not only simplifies inspection and manufacturing but also aligns with today’s sustainability goals.

At HILPCB, we manufacture a full range of PCB types — from FR4 PCB and multilayer PCB to high-speed PCB and flex PCB. With advanced production lines and strict process control, we deliver consistent quality across all PCB technologies.

Why Green FR4 PCB Is Still the Industry Benchmark

The dominance of the green solder mask is rooted in both technical merit and manufacturing practicality. Green masks provide superior optical contrast for AOI systems, reducing inspection time and error rates.

- Process stability: Green LPI solder mask offers a wide exposure tolerance and strong adhesion during reflow.

- Material consistency: Its mature formulation ensures predictable curing behavior and long-term color stability.

- Manufacturing yield: 2–3% higher first-pass yield compared to black or white masks due to better AOI performance.

This balance of process control, cost efficiency, and visual precision has made green FR4 the preferred option for more than 80% of PCB production worldwide.

Environmental and Cost Efficiency in Green FR4 PCB Manufacturing

Sustainability is now a core value in electronics manufacturing. Green FR4 PCB naturally supports eco-friendly production, offering environmental safety, energy efficiency, and economic advantages that few alternatives match.

1. Lead-Free and Halogen-Free Compliance

Modern green solder masks are RoHS and REACH compliant, free of hazardous substances such as lead, mercury, and cadmium. At HILPCB, we also support halogen-free PCB fabrication using materials below 900 ppm chlorine and bromine. When paired with high-Tg PCB or metal-core PCB, green FR4 delivers robust thermal performance while maintaining full environmental certification.

2. Energy and Material Efficiency

Green solder masks cure faster and at lower temperatures than specialty colors, lowering both energy use and carbon footprint. Their broad process window reduces rejects, rework, and material waste. This makes them especially suitable for high-volume assembly, where energy savings and stability directly impact production economics.

3. Cost Optimization in Scalable Production

From consumer to industrial electronics, green FR4 offers tangible cost benefits:

- Global standardization reduces pigment and supply costs.

- Broad compatibility across PCB stack-ups simplifies procurement.

- Lower AOI false-call rates improve yield and throughput.

By combining sustainability with process simplicity, green FR4 remains the most cost-effective PCB solution for scalable manufacturing.

Manufacturing Quality and Process Control

At HILPCB, each green FR4 board is produced under strict process discipline:

- Surface preparation: Micro-etching ensures excellent adhesion for solder mask application.

- Coating & curing: Two-stage baking achieves uniform cross-linking for durability.

- Inspection: AOI and cross-section analysis confirm plating integrity and via reliability.

- Electrical testing: Final impedance validation using our in-house impedance calculator.

Through these steps, we maintain consistent quality from prototype to large-volume assembly, meeting IPC Class 3 and automotive-grade standards.

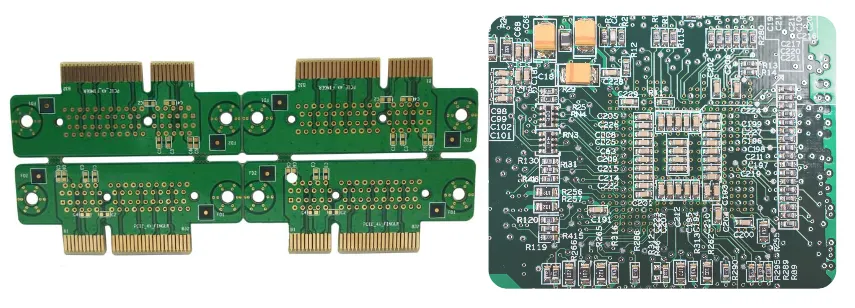

Applications of Green FR4 in Modern Electronics

Green FR4 PCBs are widely adopted in multiple industries that value balance between performance, cost, and environmental compliance:

- Consumer Electronics: Smartphones, wearables, and smart home devices.

- Industrial Control Systems: PLCs, power modules, and automation boards.

- Telecom Infrastructure: Routers and 5G base stations utilizing high-frequency PCB layers.

- Automotive Electronics: Lighting systems and infotainment units built with rigid-flex PCB.

For specialized applications requiring extra heat dissipation or reliability, we also offer heavy copper PCB and HDI PCB manufacturing solutions.

Sustainable Manufacturing Expertise from HILPCB

As a comprehensive PCB manufacturer, HILPCB combines green manufacturing practices with advanced engineering. Our production supports full turnkey options — from small-batch assembly to complete turnkey assembly — ensuring high-quality, sustainable PCB solutions at any scale.

By choosing green FR4 PCBs from HILPCB, customers gain reliable performance, environmental compliance, and cost savings without compromise.