The global electronics market continues to evolve at unprecedented speed, driven by demand for smaller devices, faster processing, and enhanced functionality. At the heart of every next-generation smartphone, wearable, and IoT device is the high density interconnect PCB—a precision-engineered HDI circuit board that delivers maximum circuit density, superior signal integrity, and miniaturized form factors that were impossible just a decade ago.

Our advanced manufacturing capabilities enable brands to deliver HDI board designs that balance technical excellence with rapid time-to-market, ensuring your products stand out in both performance and competitive positioning. From HDI PCB substrate selection to final HDI PCB assembly, we provide comprehensive solutions for modern electronics manufacturing.

Cost-Optimized HDI Printed Circuit Board Manufacturing

Delivering reliable HDI printed circuit boards requires balancing performance with cost. In ultra-compact smartphone designs and wearable electronics, every design choice, material selection, and manufacturing process directly impacts unit price and product quality for your HDI circuit board.

1. Engineering for Manufacturability (DFM/DFA) We run full DFM/DFA reviews—optimizing stack-up configurations, minimizing layer count in your high density interconnect PCB, and standardizing microvias PCB dimensions for automated SMT assembly. For high-speed medical device circuits and automotive electronics, impedance modeling and signal integrity simulation cut costly re-spins by 30%+.

2. Material Strategy for HDI PCB Substrate Materials drive up to 40% of HDI board manufacturing costs. We source certified low-loss laminates for telecommunications equipment, premium FR4 PCB grades for consumer electronics, and advanced high-Tg materials for industrial automation. In-house HDI PCB substrate inventories reduce lead time and price volatility for your HDI printed circuit board projects.

3. Advanced Blind Via PCB and Buried Via PCB Processes Our multilayer PCB production lines support precision blind via PCB structures with 0.1mm microvias PCB capabilities and ±20μm placement accuracy. Buried via PCB technology enables complex routing in compact aerospace applications and military-grade equipment. AOI, 3D paste inspection, X-ray, and SPC ensure real-time quality control for every HDI circuit board while minimizing scrap and rework.

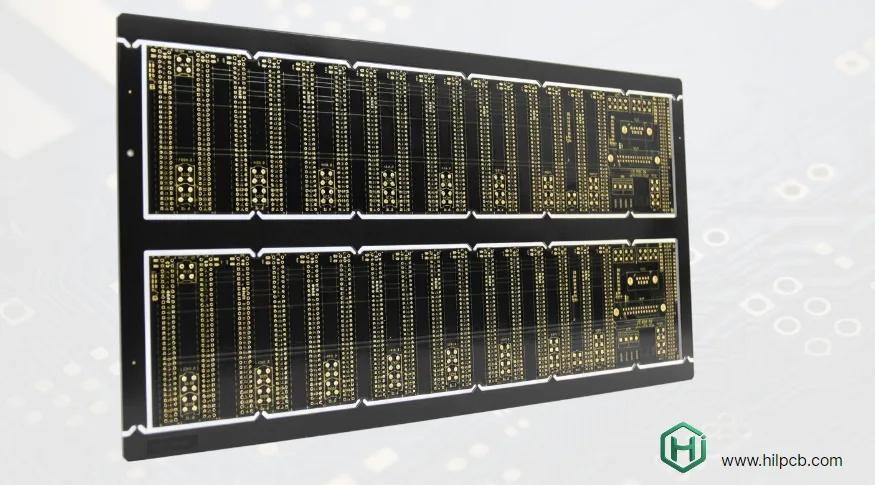

4. Yield Optimization for High Density Interconnect PCB CAD-based panel nesting maximizes HDI board count per panel for IoT sensor modules and smart home devices. Multi-product panelization shares tooling costs across SKUs for fitness trackers and portable medical monitors, while yield data drives continuous improvement in blind via PCB and buried via PCB reliability.

5. Lifecycle Quality Assurance for HDI PCB Assembly We test beyond final inspection—thermal cycling for automotive dashboard electronics, humidity exposure for outdoor IoT devices, and reliability testing for mission-critical telecommunications infrastructure. This reduces warranty claims for your HDI printed circuit board products and strengthens brand reliability in competitive consumer markets.

By combining precision engineering, smart sourcing, automation, and lifecycle QA, we deliver high density interconnect PCB solutions that meet strict standards for drone flight controllers, virtual reality headsets, and 5G networking equipment while keeping production cost-effective—helping brands scale faster and maintain strong margins.

Managing Thermal Performance in Microvias PCB Design

In ultra-compact electronic devices like smartwatches, wireless earbuds, and handheld gaming consoles, thermal stability is critical to HDI circuit board performance, reliability, and product longevity. Heat buildup during operation can shorten component life in your HDI board, cause system throttling in smartphones, and lead to premature failure in action cameras—issues that directly affect user satisfaction and brand reputation.

Key elements of our thermal management strategy for HDI printed circuit board manufacturing include:

- Pre-layout thermal simulation to detect potential hotspots early in blind via PCB and buried via PCB design for tablet computers and portable scanners

- Strategic copper plane distribution in high density interconnect PCB layouts for power banks and wireless charging pads

- High thermal conductivity laminates in HDI PCB substrate construction for laptop motherboards and gaming peripherals

- Localized heat dissipation design around processors in smartwatches, power management ICs in fitness bands, and RF modules in cellular modems

- Integration of thermal vias in microvias PCB structures to move heat from surface components to inner copper planes in VR controllers and augmented reality glasses

- Material and stack-up optimization in HDI board fabrication to balance thermal control with electrical performance for automotive radar systems and industrial sensors

By applying these measures to every HDI circuit board, we ensure stable operation even in tightly enclosed housings for smart speakers and home automation hubs, reduce RMA rates for wearable health monitors, and meet international safety standards—helping brands deliver HDI PCB assembly products for e-readers and portable projectors that are reliable, durable, and more likely to drive repeat sales.

Accelerating Time-to-Market for High Density Interconnect PCB Products

Speed as a Competitive Advantage In the consumer electronics industry—especially in the smartphone, fitness tracker, and wireless audio segments—market windows are short, and launch timing can define a product's success. Delays of even a few weeks can mean missing peak sales periods for smart home devices or losing ground to competitors in the drone racing market.

Integrated Manufacturing Workflow for HDI Printed Circuit Board Our streamlined HDI PCB manufacturing process for action cameras, handheld game consoles, and portable medical devices combines:

- Early DFM (Design for Manufacturability) Review — identifying and resolving microvias PCB design risks before fabrication of your HDI circuit board for e-cigarettes, digital thermometers, or GPS tracking devices.

- Rapid Prototyping — producing functional blind via PCB and buried via PCB prototypes for smart jewelry, pet trackers, and baby monitors in days, not weeks.

- High-Volume HDI PCB Assembly — scalable production for automotive dashcam units, security camera modules, and retail point-of-sale terminals with automated optical inspection (AOI) and in-line quality checks.

Reduced Lead Times, Lower Risk for HDI Board Production By handling both HDI printed circuit board fabrication and turnkey assembly under one roof for industrial barcode scanners, handheld payment terminals, and portable ultrasound machines, we eliminate inter-supplier communication gaps, reduce logistics delays, and ensure that design intent is preserved throughout high density interconnect PCB production. The result is faster market entry for wireless presentation systems and pocket projectors with no compromise on quality.

Market Responsiveness for HDI Circuit Board Applications This agility enables you to:

- Synchronize product launches of smart thermostats and voice assistants with key retail seasons.

- Respond rapidly to emerging trends in wireless earbuds, smart rings, and health monitoring patches.

- Iterate and improve HDI board designs quickly for electric scooter controllers and e-bike displays without lengthy requalification cycles.

Customization for Advanced HDI PCB Substrate Applications

High density interconnect PCB technology is no longer limited to general consumer electronics—HDI printed circuit boards now serve diverse verticals such as surgical robotics, autonomous vehicle systems, factory automation PLCs, and satellite communication equipment. Each use case demands a uniquely optimized HDI circuit board design, whether it's for integrating high-speed interfaces in data center switches using blind via PCB technology, or enabling ultra-reliable operation in implantable cardiac monitors with buried via PCB structures.

We support custom layer stack-ups for industrial machine vision cameras, controlled impedance routing in test and measurement instruments, and advanced microvias PCB structures tailored to the specific electrical, mechanical, and environmental constraints of your HDI board for professional audio equipment or broadcast video switchers. For applications like 5G base stations or automotive LIDAR systems, we incorporate high-frequency PCB materials, precise trace geometry in your HDI PCB substrate, and low-loss dielectrics for military radar and aerospace navigation—all within compact form factors for underwater drones and handheld spectroscopy devices.

With deep expertise in high-speed PCB design for edge computing modules, signal integrity optimization in HDI printed circuit board layouts for telecommunications routers, and environmental durability in HDI PCB assembly for outdoor sensor networks, we help brands move beyond generic solutions and dominate niche markets with technically differentiated products. Our box build assembly service ensures complete integration from HDI circuit board to final product testing for laboratory instruments, robotics controllers, and aviation avionics.

End-to-End Solutions for HDI Board Success

Launching competitive electronic products like smart thermometers, wireless charging pads, or industrial HMI panels requires more than a well-designed high density interconnect PCB—it demands an integrated partner that manages every step from concept to mass production for your HDI printed circuit board projects.

Our capabilities for HDI Circuit Board manufacturing include:

- Complete design verification and DFM analysis for microvias PCB structures in handheld diagnostic tools and portable oscilloscopes

- Flexible PCB and rigid-flex HDI board options for space-constrained applications like foldable smartphones and wearable insulin pumps

- Advanced testing including flying probe, ICT, and functional validation for blind via PCB and buried via PCB in smart glasses and AR headsets

- Supply chain management and component sourcing for turnkey HDI PCB assembly projects ranging from smart door locks to industrial vibration sensors

By consolidating these services under one roof for HD camera modules, wireless microphone systems, and portable laser distance meters, we cut lead times, reduce risk, and enable smooth scaling—from small batch assembly of prototype smart rings to large volume assembly of consumer fitness bands. This integrated workflow ensures faster launches of HDI PCB substrate-based products like e-paper displays and biometric readers, consistent quality across every high density interconnect PCB, and greater profitability for every HDI printed circuit board program serving markets from mobile payments to marine electronics.