Material choice defines the reliability, cost, and performance of every HDI PCB substrate. Using the wrong laminate—like standard FR-4 in high-heat environments—can lead to premature failure, while over-specifying polyimide raises costs unnecessarily.

At HILPCB, we manufacture HDI boards using a full range of substrates—from cost-efficient FR4 laminates to high-thermal solutions and hybrid RF stack-ups. when RF performance is required, we use HDI-compatible low-loss organics (e.g., PTFE blends or hydrocarbon/ceramic-filled laminates) within mixed stack-ups. Our experience across thousands of designs ensures balanced solutions that meet electrical, thermal, and mechanical requirements without overspending.

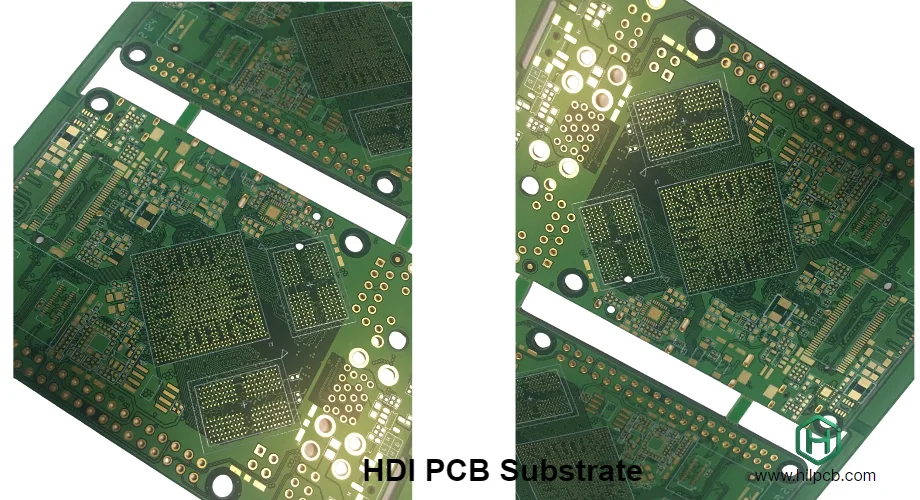

HDI Substrate Selection for Microvia Reliability (Tg, CTE, Resin, Foil & Process)

Microvia reliability sits at the heart of HDI performance. Substrate chemistry, glass style, copper foil profile, and process windows jointly determine whether stacked microvias survive reflow and field cycling.

1) Tg & Resin System

- FR-4 (HDI-grade, Tg 150–170 °C): adequate for most consumer/industrial boards; choose low-flow, low-shrink resins to limit cavity growth and resin recession around vias.

- High-Tg FR-4 (≥180 °C): adds thermal headroom for lead-free reflow, heavy copper zones, or modest under-hood temps; improves pad/via stability.

- Polyimide (>250 °C): for continuous high-temp or harsh environments; higher cure temps and tighter moisture control required.

2) CTE Matching & Glass Style

- Aim for through-thickness CTE control to reduce z-axis expansion at reflow. Spread-glass styles minimize weave-induced skew and resin-rich pockets that stress microvias.

- For stacked vias, combine low-CTE dielectrics near via barrels with controlled copper balancing to reduce bow/twist.

3) Copper Foil & Profile

- Use low-profile/very-low-profile (LP/VLP) foils on high-speed layers to curb loss and reduce copper-resin interface stress.

- For power layers, heavier copper is fine, but balance copper weights symmetrically to avoid warpage that cracks stacked vias.

4) Via Architecture & Fill

- Prefer staggered stacks for cost-sensitive designs; stacked is acceptable with resin or copper fill and tight plating control.

- Specify resin-filled microvias and VIPPO (via-in-pad plated over) at fine-pitch BGAs to minimize inductance and collapse risk.

5) Lamination & Drill

- Sequential lamination with controlled thermal profiles reduces cumulative stress.

- Laser parameters (energy, pulse width) must match resin chemistry; over-burn induces carbonization and weak interfaces.

- Backdrill only through-vias that would create stubs—do not backdrill microvias.

6) Qualification & Monitoring

- Use IST/thermal cycling (e.g., 6× reflow + −40/125 °C cycles) with cross-sections to confirm no interfacial separation.

- Add coupon-level TDR and microsection on each panel; track CpK for hole fill and collar thickness.

7) Typical HDI Stack-Up Patterns (Examples)

- Mobile/Wearable: FR-4 HDI-grade core + VLP foils; 1–2 buildup per side; staggered microvias; ENIG finish.

- Industrial/Auto (moderate temp): High-Tg FR-4 core; heavier copper rails; resin-filled VIPPO under BGA; 2× buildup one side.

- RF-enhanced HDI: Hybrid with low-loss cores (e.g., RO4350B) only at RF layers; rest FR-4/High-Tg; maintain compatible press cycles.

This approach ties material selection directly to microvia survivability, ensuring HDI reliability through assembly and life-cycle stress.

FR-4: The Standard for Cost-Effective HDI Boards

Modified FR-4 remains the most common HDI base material due to its balance of price, stability, and manufacturability. HDI-grade FR-4 provides excellent laser-drilling response, dimensional control, and yield optimization.

Typical benefits:

- Cost-efficient: $12–18/m² versus $40+ for advanced materials

- Tg around 150–170 °C, suitable for consumer and industrial electronics

- Compatible with lead-free processes and sequential lamination

High-Tg and Halogen-Free FR-4 Variants:

For higher thermal margins or regulatory compliance, high-Tg laminates offer Tg ≥180 °C and better mechanical stability, while halogen-free options meet RoHS/REACH without sacrificing electrical properties. Both variants add only 10–25% cost over standard FR-4 but significantly improve durability and compliance.

Polyimide: For Extreme Thermal and Flexible Designs

When continuous operation exceeds 150 °C or mechanical flex is required, polyimide substrates outperform FR-4. Their high Tg (>250 °C) and low CTE improve reliability in harsh environments such as aerospace, automotive, and industrial applications.

Rigid Polyimide Advantages:

- Withstands 200 °C peaks during soldering or operation

- Superior chemical resistance and dimensional stability

- Ideal for mission-critical and long-life products

Flexible Polyimide for Rigid-Flex HDI:

Thin (25–125 µm) flex-grade films support lightweight, compact interconnects. Combined with rolled-annealed copper, they offer excellent bend endurance for wearables, robotics, and medical devices. Our rigid-flex PCB manufacturing integrates HDI layers with flexible zones to simplify assembly and improve reliability.

Specialized Substrates for Advanced Applications

High-Frequency and RF Circuits

For 5G and microwave systems, low-loss HDI-compatible organics like Rogers RO4350B or RO4835 provide stable dielectric performance (Df≈0.004). Hybrid stack-ups place these materials only on RF layers while keeping FR-4/High-Tg elsewhere to control cost.

Metal-Core for Power and Thermal Management

Metal-core PCBs with aluminum or copper bases provide superior heat dissipation (1–8 W/m·K vs. ~0.3 for FR-4). Ideal for LED, EV power converters, and high-current circuits, these are typically used as separate thermal carrier boards or in hybrid assemblies, not as HDI buildup bases.

IC Substrates for Ultra-High Density

When feature sizes fall below 50 µm, IC substrate technology bridges PCB and semiconductor packaging. Modified polyimide/epoxy systems support 10+ buildup layers per side and ultra-fine lines (0.03 mm) for advanced processors and AI accelerators. Our IC substrate PCB services cover 2.5D and fan-out packaging applications.

Choosing the Right Material: Key Considerations

1. Application and Environment

- <130 °C: Standard or high-Tg FR-4

- 130–150 °C: High-Tg or halogen-free FR-4

- >150 °C: Polyimide or hybrid stack-ups

- High frequency (>1 GHz): HDI-compatible low-loss organics (PTFE blends/hydrocarbon-ceramic filled)

2. Cost vs. Performance

Material cost is ~15–25% of total HDI cost. Moving from FR-4 to polyimide may raise total cost 30–40%. Use hybrid stack-ups and selective RF layers to meet performance targets without upgrading all layers. Sometimes adding 2–4 layers on FR-4 costs less than switching to premium materials.

3. Reliability and Certification

Safety-critical markets (automotive, aerospace, medical) often justify higher-grade materials to ensure long-term stability. For commercial products, warranty targets and usage environment drive the final choice more than peak assembly temperatures.

How HILPCB Helps Optimize Your HDI Material Choice

Engineering-Driven Material Selection

We match operating conditions, electrical specs, and cost goals to substrates with the right Tg, CTE, and loss profile. Trade-offs are explained clearly—so you can choose between FR-4, high-Tg, polyimide, or hybrid RF options with confidence.

Prototyping and Validation

We provide small-batch builds across multiple material options to compare performance under real use conditions. Quick-turn prototyping in 10–12 days helps validate microvia reliability and RF loss before committing to mass production.

Consistent Supply and Traceability

HILPCB sources exclusively from authorized distributors and maintains full material traceability. Controlled storage prevents moisture absorption, ensuring dimensional stability and repeatable processing for every production lot.

FAQ: Common Questions About HDI PCB Materials

Can I use FR-4 for HDI boards?

Yes—most designs under 130 °C work reliably on HDI-grade FR-4. High-Tg versions provide extra margin for lead-free reflow and power circuits.

When is polyimide necessary?

Choose polyimide for continuous high temperatures, harsh chemicals, or high vibration. It maintains dimensional/mechanical stability where FR-4 can degrade.

Can different materials be combined?

Yes. Hybrid stack-ups mixing FR-4, high-Tg, and low-loss RF laminates balance cost and performance. We model thermal/CTE behavior and define press cycles to keep lamination reliable.

How does material choice affect assembly?

High-Tg and polyimide reduce warpage through reflow; low-loss RF layers may require adjusted solder profiles. Our assembly team provides profiles and DFM guidance for each material set.

Selecting the right HDI PCB substrate starts with microvia reliability and the target environment—then balancing cost and RF needs with hybrid stack-ups as required. With HILPCB’s engineering support and multi-material manufacturing, you can confidently build HDI boards that meet performance, reliability, and budget goals. Contact us for a material consultation and tailored quote.