The accelerating growth of artificial intelligence, cloud infrastructure, and hyperscale data centers is redefining the performance standards for modern server hardware. At HILPCB, we specialize in manufacturing high density interconnect (HDI) PCBs engineered for AI servers, compute motherboards, and enterprise systems that demand exceptional signal integrity, high-current PDN stability, and long-term reliability.

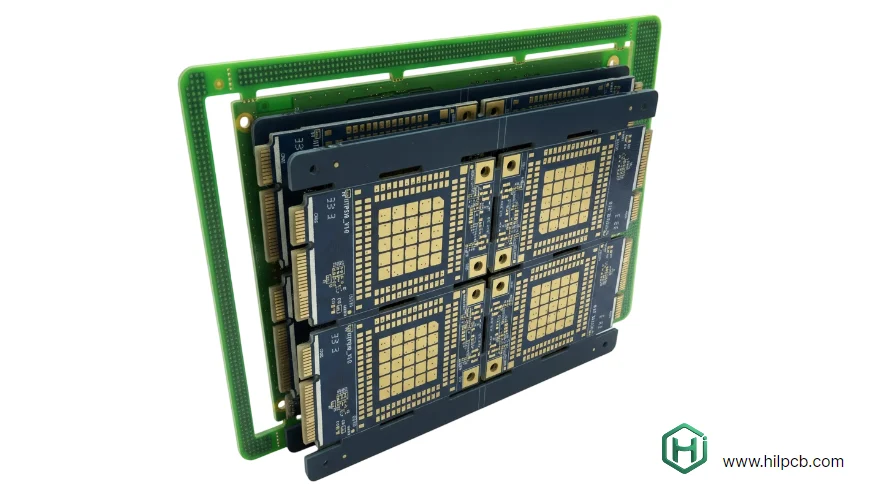

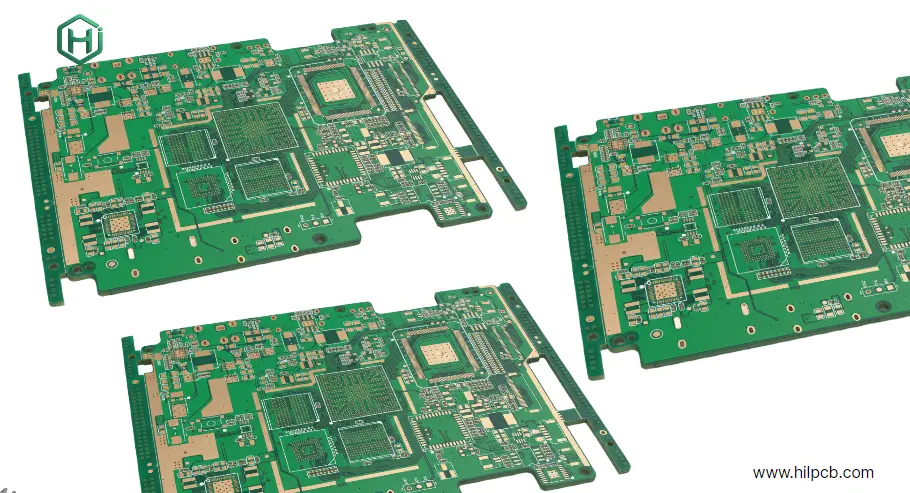

Our HDI circuit boards are the foundation of today’s compute infrastructure—supporting multi-core processors, terabytes of memory, and 112G/224G SerDes interconnects within thermally demanding rack environments. From high-layer-count server motherboards to GPU accelerator and backplane boards, we deliver precision-built HDI solutions that ensure performance consistency under continuous 24/7 operation.

By combining advanced PCB engineering, controlled-impedance fabrication, and turnkey HDI PCB assembly, we help OEMs and cloud providers accelerate product launches while meeting the strict reliability and compliance requirements of data center environments.

Cost-Optimized High Density Interconnect PCB Manufacturing

Delivering reliable high density interconnect PCBs for servers requires balancing cutting-edge performance with total cost of ownership. In dense server designs, every design choice, material, and process directly impacts system reliability and operational costs.

1. Engineering for Manufacturability (DFM/DFA) We run full DFM/DFA reviews—optimizing power distribution networks, analyzing signal integrity for PCIe Gen5/Gen6, and validating thermal vias for SMT assembly. For high-speed SerDes interfaces, impedance modeling and crosstalk analysis prevent costly respins.

2. Material Strategy Materials are critical for server reliability. We source high-speed PCB laminates for 56G/112G PAM4 signaling, heavy copper PCB layers for power distribution (up to 6 oz), and high-Tg PCB cores for continuous high-temperature operation.

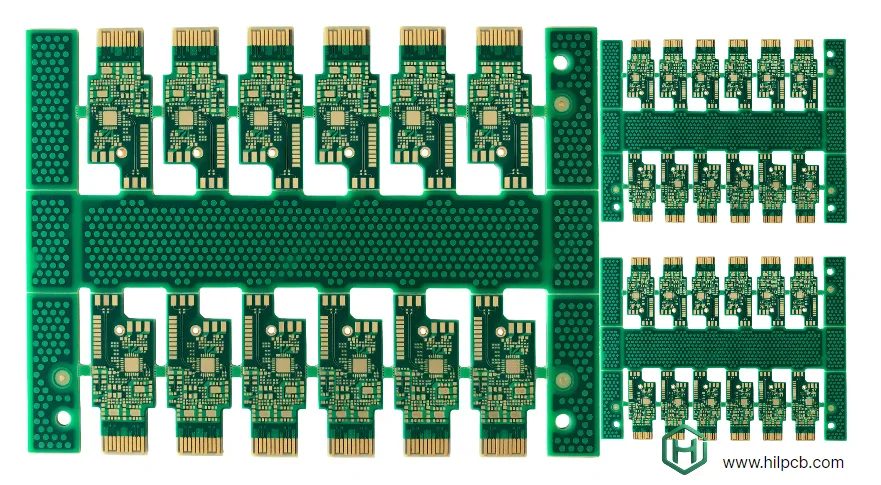

3. Automated Processes Our backplane PCB production lines support 20-40 layer counts with sequential lamination, controlled impedance testing, and 100% electrical continuity validation. X-ray inspection and cross-sectional analysis ensure via reliability.

4. Yield Optimization Server PCBs integrate expensive processors and memory. We implement advanced process control, automated defect detection, and statistical yield analysis to maintain >98% first-pass yield—critical for competitive server economics.

5. Lifecycle Quality Assurance Servers operate 24/7 for years in thermally demanding conditions. We perform accelerated life testing, thermal cycling per JEDEC standards, and vibration testing. This reduces field failures and extends system service life.

By combining precision engineering, server-grade materials, automation, and rigorous testing, we deliver high density interconnect PCBs that meet data center reliability requirements while maintaining competitive pricing.

Managing Power Integrity in High-Density Server PCB Design

In modern servers with multi-core processors drawing hundreds of amperes, power integrity is critical to system stability and performance. Voltage droop, ground bounce, and power supply noise can cause system crashes, data corruption, and performance degradation.

Key elements of our power integrity strategy for high density interconnect PCB include:

- Power distribution network (PDN) simulation modeling impedance across the frequency spectrum

- Multi-layer power plane design with optimized decoupling capacitor placement strategies

- Low-inductance via structures minimizing PDN impedance for fast transient response

- Strategic copper weight selection using heavy copper PCB for high current carrying capacity

- Bulk and high-frequency decoupling optimized for processor power delivery networks

- Ground plane continuity providing low-impedance return paths and reducing EMI

By implementing comprehensive power integrity design practices, we ensure high density interconnect PCBs deliver clean, stable power to high-performance processors—enabling maximum system performance and uptime in demanding data center environments.

Accelerating Time-to-Market for Server Platforms

Speed as Competitive Imperative In the rapidly evolving server market, time-to-market determines competitive positioning. New processor generations, memory standards, and networking technologies create narrow windows for platform deployment.

Integrated Manufacturing Workflow Our high density interconnect PCB production process combines:

- Advanced Signal Integrity Verification — pre-production validation of PCIe Gen5/6, DDR5, and 400G Ethernet interfaces.

- Rapid Complex Prototyping — delivering 20+ layer server boards in 10-12 days.

- Scalable Production Capacity — supporting large volume assembly for data center deployments.

Reduced Lead Times, Lower Risk By consolidating PCB fabrication and turnkey assembly under one roof, we eliminate supply chain delays and accelerate qualification timelines. This integration enables faster market entry while maintaining the quality required for enterprise deployment.

Market Responsiveness This operational efficiency enables you to:

- Capture early market opportunities for next-generation server platforms.

- Respond rapidly to customer requirements and cloud provider specifications.

- Deploy performance optimizations without extended qualification cycles.

Customization for Advanced Server Architectures

Modern data centers serve diverse workloads—from dual-socket general-purpose servers to GPU-accelerated AI training systems to disaggregated composable infrastructure. Each architecture demands optimized high density interconnect PCB designs for specific compute, memory, and networking requirements.

We provide specialized engineering for demanding applications including IC substrate PCB for advanced packaging, high thermal PCB for GPU computing accelerators, and backplane PCB for blade server chassis interconnect.

With expertise in server architecture, high-speed signaling (PCIe, CXL, DDR), and compliance with OCP and PICMG standards, we help server manufacturers deploy high density interconnect PCBs that enable next-generation data center performance.

End-to-End Solutions for Server PCB Programs

Launching competitive server products requires more than PCB manufacturing—it demands comprehensive engineering support throughout the product lifecycle.

Our capabilities include:

- Complete signal and power integrity analysis using industry-standard simulation tools

- Component engineering and supply chain management for complex server BOMs

- Advanced functional testing including system-level validation and burn-in

- Box build assembly for complete rack-level integration

By consolidating these services, we reduce development risk, accelerate qualification timelines, and ensure consistent quality—from small batch assembly for pre-production to volume manufacturing for data center deployments. This comprehensive approach delivers high density interconnect PCBs optimized for modern computing infrastructure.