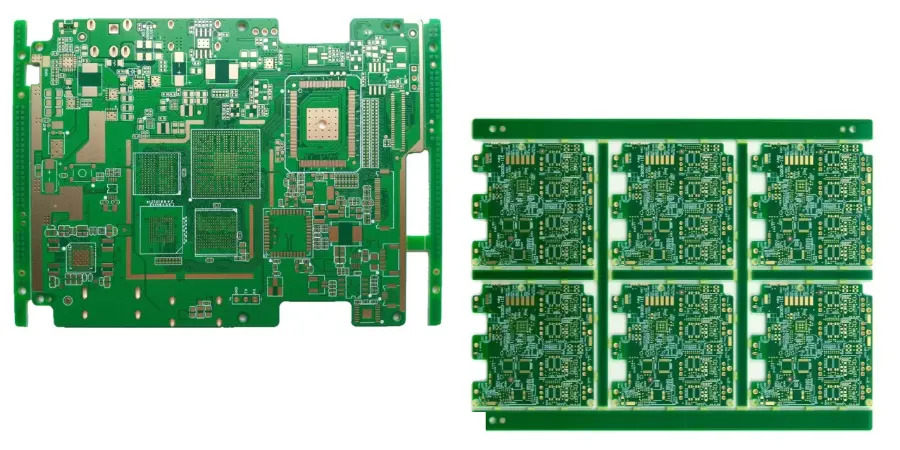

High-density PCBs are the foundation of today's intelligent devices. As components become smaller and circuit complexity increases, manufacturers must deliver more layers, tighter spacing, and better signal integrity in limited board space. Highleap PCB Factory specializes in building high-density PCB boards that support these next-generation requirements—without sacrificing production speed or quality.

Our high-density PCB services are trusted by teams building advanced computing modules, embedded communication interfaces, and precision industrial systems. With support for HDI stackups, fine-pitch vias, and impedance control, we produce compact PCBs with consistent performance across batch sizes.

HDI Stackups and Complex Layer Routing

At Highleap PCB Factory, we handle a wide range of high-density PCB layouts with accuracy and repeatability:

- 4 to 64 multilayer configurations with blind/buried vias

- Microvia laser drilling, via-in-pad support, staggered/stacked vias

- High-Tg FR4, polyimide, and hybrid dielectric combinations

- Trace/space down to 50 µm (2 mil), copper weights from 0.5 to 3 oz

- Tight impedance control and EMI shielding structures

These features are applied to sectors like IoT gateways, edge computing, compact camera modules, and mixed-signal platforms. Explore HDI PCB and FR4 PCB products to see how they support high-density circuits with mechanical reliability.

Material Choices for High-Density PCB Construction

| Material | Application | Characteristics |

|---|---|---|

| High-Tg FR4 | Automotive, network equipment | Heat resistance, stability |

| Polyimide | Flexible HDI and rigid-flex PCBs | Thermal resilience, low CTE |

| Rogers/Ceramic | RF, analog, mixed-signal boards | Controlled Dk/Df, low loss |

| Aluminum substrates | Lighting, power applications | Thermal dissipation, mechanical base |

Our PCB manufacturing services are optimized for integrating special board materials, stackups, and signal conditions without delaying delivery timelines.

Specialized Engineering Support for High-Density Projects

Each high-density PCB order receives detailed front-end engineering support. We help clients design and prepare manufacturing data by offering:

- Pre-production stackup planning

- DFM checks and impedance simulations

- Pad/via optimization and escape routing validation

- Fine-pitch soldermask registration guidance

Highleap PCB Factory also provides online tools such as our Gerber Viewer and 3D PCB Viewer to assist design teams in finalizing production-ready files.

Beyond High-Density PCBs – Expertise in Special Material Boards

Highleap PCB Factory is not limited to high-density PCB production. We manufacture complex PCBs with specialized materials for heat, flex, or RF-critical applications, including:

- Rigid-Flex PCBs for wearables and aerospace systems

- Ultra-thin PCBs for compact electronics

- High-Tg PCBs for harsh thermal environments

- Metal-core and aluminum-backed PCBs for LED and power systems

These categories demonstrate our capacity beyond standard builds. Whether it’s HDI, thermal dissipation, or dynamic bending, we have the materials and processes ready.

Why Global Clients Choose Highleap PCB Factory

Highleap PCB Factory is a preferred high-density PCB manufacturer and assembly supplier in China. Our clients choose us for:

- Quick quoting and rapid prototyping

- Reliable quality and batch consistency

- Multilayer and HDI production flexibility

- Convenient global shipping and payment terms

- English-speaking support teams with after-sales service

Our experience with both small R&D batches and full production runs allows us to support high-performance product teams from concept to delivery.

Start Your Next High-Density PCB Project with Confidence

Whether you’re producing compact FPGA carrier boards, telecom backplanes, or embedded system cores, Highleap PCB Factory is equipped to fabricate and assemble high-density PCBs with precision. Contact us to explore how our fast turnaround, special material support, and quality assurance processes can benefit your next project.