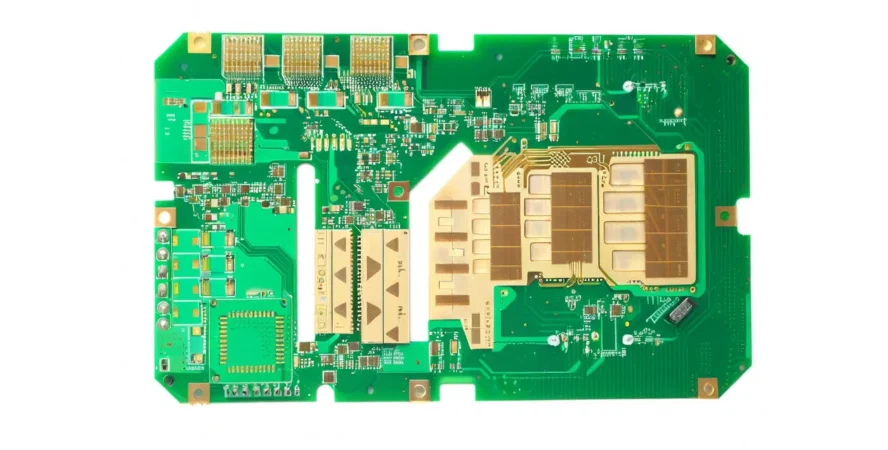

In sectors like aerospace, defense, medical devices, and automotive safety systems, there's zero margin for PCB failure. A high-reliability PCB must withstand temperature extremes, vibration, humidity, long service life, and electrical stress—without degrading signal performance or mechanical structure.

Highleap PCB Factory specializes in building and assembling high-reliability PCBs, conforming to IPC Class 2 and Class 3 standards. Our capabilities are rooted in strict quality controls, traceable processes, and expert use of advanced materials, enabling us to meet the stringent requirements of mission-critical applications.

What Makes a High-Reliability PCB Different

Unlike consumer-grade boards, a high-reliability PCB emphasizes endurance, traceability, and electrical integrity over time. This includes:

- Use of high-Tg and low-CTE substrates to resist thermal cycling

- Heavy copper layers for stable power delivery in extreme conditions

- Advanced solder mask and surface finish control to prevent oxidation

- Hole wall quality with 360° plating and no annular ring breakouts

- Comprehensive electrical test coverage (flying probe + bed-of-nails)

In our facility, many of these features are standard for production builds in high-Tg PCB, heavy copper PCB, and backplane PCB categories.

Built for Demanding Applications

We supply high-reliability PCBs for:

- Aerospace control systems and flight navigation units

- Military RF modules and power distribution boards

- Automotive LiDAR, ADAS, and engine control PCBs

- Medical imaging equipment and Class II/III devices

- Industrial robotics and high-load servo control

In such environments, reliability is not just a design target—it’s a mandatory requirement. Our multi-stage inspection, including AOI, X-ray, microsection analysis, and IPC 6012 Class 3 verification, ensures consistent quality at every step.

Material Engineering for High-Reliability Demands

Highleap PCB Factory's approach to reliability starts with the right material pairing. We don’t treat laminate selection as a formality—instead, we collaborate with engineers to tailor thermal, mechanical, and electrical performance for specific operational profiles.

Our advanced material capabilities include:

| Material Type | Application Focus |

|---|---|

| Ceramic PCB | High heat dissipation, minimal dielectric loss |

| Metal-core PCB | Vibration resistance, mechanical strength |

| Rigid-flex PCB | 3D packaging, movement tolerance in dynamic systems |

| HDI with stacked vias | Miniaturized routing for fine-pitch BGA and sensors |

| Custom stackups | Impedance control, EMI shielding, high-voltage isolation |

Every design is validated early using our in-house Gerber Viewer and 3D PCB Viewer, giving clients a clear understanding of layer interactions and clearance management. Whether it's matching copper balance for heavy-layer boards or using controlled-weave glass styles for SI-critical routes, our engineering aligns materials with mission goals.

Complete High-Reliability PCB Assembly Workflow

High-reliability doesn't end at the bare board. Highleap PCB Factory provides a tightly controlled SMT and THT assembly process optimized for IPC Class 2/3 compliance and rugged environments.

Key service integrations include:

- Detailed BOM and footprint validation using our visual 3D PCB Viewer

- Precision through-hole assembly with controlled thermal profiles and automated insertion

- End-to-end box-build assembly for ready-to-integrate modules

- Profile optimization based on solder alloy, via type, and material stack

- 100% electrical testing including flying probe, ICT, and optional burn-in cycles

All assembled units are traceable back to lot and batch, with serialized reports available for QA audits. This holistic process ensures that when you choose Highleap PCB Factory, you're not just getting a board—you're getting verified reliability from CAD to shipping.

Our services go beyond fabrication. As a high-reliability PCB assembly provider, we offer:

- BOM risk analysis and 3D PCB Viewer inspection before build

- IPC-A-610 Class 2/3 SMT and through-hole assembly

- Turnkey options from board to box-build

- Thermal profile tuning per solder alloy and design spec

- Full test coverage: ICT, flying probe, FCT, conformal coating

This ensures that every board we ship is qualified not just for short-term use—but for years of mission-critical performance.

Why Engineers Trust Highleap PCB Factory

With decades of experience and projects deployed globally, Highleap PCB Factory continues to be a reliable partner for high-reliability PCB fabrication and assembly.

We combine:

- Special material expertise and hybrid board structures

- Advanced inspection, DFM checks, and IPC-class verification

- Cleanroom-controlled lamination and automated inspection

- Fast global delivery and technical support

If you’re designing a system that cannot tolerate PCB failure, trust a manufacturer that builds for performance and longevity—trust Highleap PCB Factory.