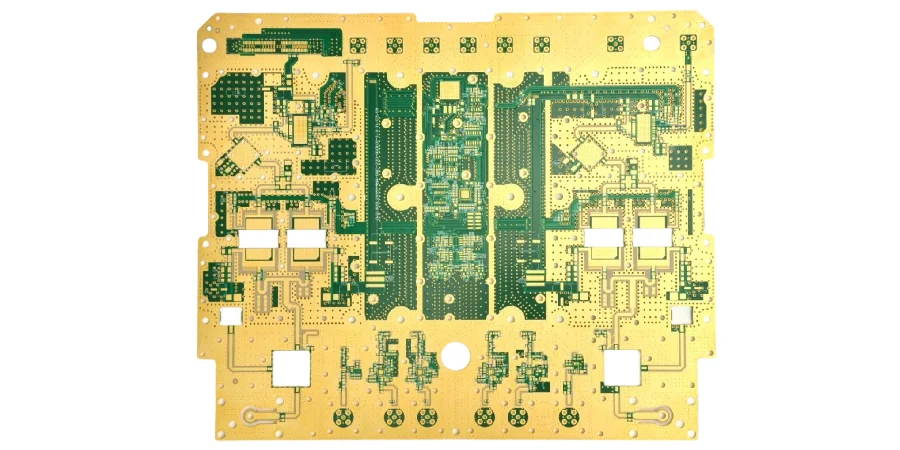

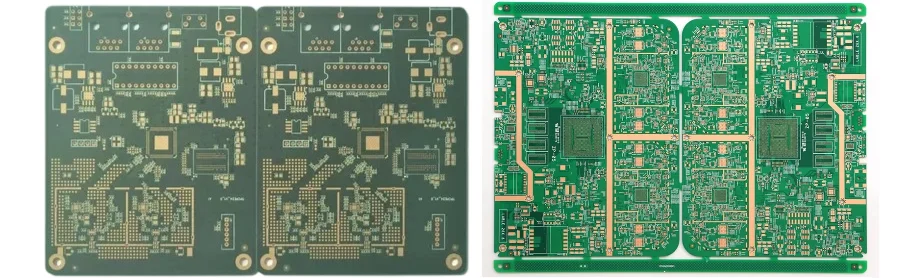

At Highleap PCB Factory (HILPCB), we specialize in the manufacturing of a wide range of advanced PCBs, with a particular focus on high-frequency and complex designs. One of our key offerings is Immersion Gold (ENIG) PCB, which provides superior solderability, corrosion resistance, and long-term reliability. This surface finish is ideal for applications that require precision and excellent electrical performance, making it a preferred choice in industries such as telecommunications, medical devices, and automotive systems. Our expertise extends across various PCB types, ensuring high-quality and reliable solutions for diverse high-performance electronic needs.

What is Immersion Gold PCB?

Immersion Gold PCB is a surface finish applied through a chemical process where a thin layer of gold is deposited over a nickel layer that has been previously applied to the copper pads of the PCB. This process is part of the ENIG (Electroless Nickel Immersion Gold) system, which is widely used in the PCB industry. The nickel layer provides a durable and stable foundation for the gold layer, which in turn offers a highly conductive and corrosion-resistant surface.

The primary benefit of Immersion Gold is its excellent performance in solderability, especially with lead-free soldering processes. The gold layer provides a clean, flat, and uniform surface, which is crucial for ensuring reliable electrical connections in fine-pitch components and high-density interconnects. Immersion gold’s low contact resistance and resistance to oxidation make it especially suitable for high-reliability applications, where long-term durability and performance are critical.

Benefits of Immersion Gold PCB

The Immersion Gold PCB process offers several key advantages, making it an ideal choice for various high-performance applications. These benefits include:

1. Excellent Solderability

The primary benefit of Immersion Gold PCBs is their excellent solderability. The gold layer provides a smooth surface that ensures reliable solder joints, particularly in lead-free soldering applications. This makes Immersion Gold ideal for fine-pitch components and high-density interconnects (HDI), where achieving consistent, high-quality solder joints is critical.

2. Corrosion Resistance

The combination of nickel and gold provides robust protection against oxidation, ensuring that the PCB’s surface remains intact and solderable over time. This makes Immersion Gold PCBs a reliable choice for applications that require extended shelf life or exposure to harsh environmental conditions.

3. Durability and Stability

Immersion Gold’s long-term stability ensures that the finish remains intact throughout the PCB's lifecycle, even after multiple reflow cycles or extended storage. The nickel-gold finish provides superior resistance to wear and tear, making it suitable for mission-critical applications in industries like aerospace and medical devices.

4. Ideal for High-Speed and High-Frequency Applications

The gold layer’s low contact resistance and uniformity make Immersion Gold PCBs an excellent choice for high-speed and high-frequency applications. The smooth, clean surface minimizes signal degradation, ensuring that the PCB performs reliably even at high frequencies. This makes it particularly suitable for telecommunications, RF circuits, and digital signal processing systems.

5. Compatibility with Automation

The smooth and flat nature of the Immersion Gold finish makes it compatible with automated soldering processes, which is essential for large-scale manufacturing and high-throughput PCB assembly. The finish facilitates high yields in mass production while maintaining excellent performance.

Applications of Immersion Gold PCBs

Immersion Gold PCBs are ideal for applications that demand excellent solderability, long-term reliability, and high electrical performance. Some common use cases include:

- Telecommunications: Immersion Gold PCBs are commonly used in high-frequency PCBs for communication systems, ensuring minimal signal loss and reliable data transmission in satellite systems and RF circuits.

- Medical Devices: The durability and reliability of Immersion Gold make it suitable for medical equipment, where performance and longevity are paramount. These PCBs are used in diagnostic devices, patient monitoring systems, and surgical instruments.

- Consumer Electronics: Immersion Gold is widely used in consumer electronics, including smartphones, laptops, and wearables, where fine-pitch components and high-density connections are crucial for performance.

- Automotive Electronics: In the automotive sector, Immersion Gold PCBs are used for critical control systems, sensors, and power electronics, where long-term reliability and high conductivity are essential.

- Industrial Electronics: Immersion Gold is also used in industrial systems where PCBs need to endure challenging environments and perform reliably over time.

Comparing Immersion Gold to Other Surface Finishes

While Immersion Gold offers many advantages, it is important to compare it with other common PCB surface finishes such as HASL and OSP:

Immersion Gold vs HASL

HASL (Hot Air Solder Leveling) is a traditional PCB surface finish, but it has limitations in terms of flatness and uniformity, particularly for fine-pitch components. Immersion Gold, on the other hand, provides a smoother and more uniform surface that ensures better solderability and is ideal for high-speed and high-frequency applications. While HASL is more cost-effective, Immersion Gold provides superior long-term performance, especially in high-reliability applications.

Immersion Gold vs OSP

OSP (Organic Solderability Preservative) is an eco-friendly, cost-effective surface finish, but it offers less protection against oxidation compared to Immersion Gold. While OSP is suitable for less demanding applications, Immersion Gold offers better long-term reliability, making it more suitable for applications in automotive and telecommunications where stability and durability are crucial.

Why Choose Highleap PCB Factory for Immersion Gold PCBs?

At Highleap PCB Factory (HILPCB), we offer high-quality Immersion Gold PCBs that meet the most stringent standards for performance and reliability. Our comprehensive PCB manufacturing process ensures that every immersion gold PCB meets the exact specifications required for your project, whether you need heavy copper PCBs for power electronics or flex PCBs for compact designs. Additionally, we offer turnkey assembly services to streamline your PCB production from start to finish.

Our experienced engineers work closely with you to optimize your designs for Immersion Gold, ensuring that the final product delivers maximum performance and reliability. We also provide detailed support for multilayer PCBs and complex designs to meet the evolving demands of modern electronics.

For more details, explore our other products, such as ceramic PCBs, rigid-flex PCBs, and IC substrate PCBs.

FAQ

1. What makes Immersion Gold different from other finishes like ENIG? Immersion Gold is a cost-effective surface finish offering excellent solderability and electrical performance. ENIG offers higher durability but is more expensive, making Immersion Gold an ideal choice for medium-complexity designs where solderability and affordability are priorities.

2. How does Immersion Gold compare to HASL? While HASL is cheaper, Immersion Gold provides a smoother, more uniform surface, making it better for fine-pitch components and high-frequency applications where reliable performance is crucial.

3. What industries use Immersion Gold PCBs? Immersion Gold is used in industries such as consumer electronics, telecommunications, medical devices, and automotive electronics, where high solderability, long-term reliability, and excellent electrical performance are required.

4. Is Immersion Gold suitable for high-density applications? Yes, Immersion Gold is ideal for high-density applications, especially for fine-pitch components and high-frequency PCBs. Its smooth surface ensures excellent solderability, making it perfect for high-density interconnects and complex designs.

5. Can Immersion Gold withstand multiple reflow cycles? Yes, Immersion Gold offers excellent durability, making it suitable for applications that require multiple reflow cycles, such as in automotive and medical electronics where high reliability is critical.

6. What are the environmental advantages of Immersion Gold? As a RoHS-compliant finish, Immersion Gold is a lead-free solution, making it an environmentally sustainable option compared to traditional finishes like HASL, which may contain lead. The process is also non-toxic, ensuring a lower environmental impact.