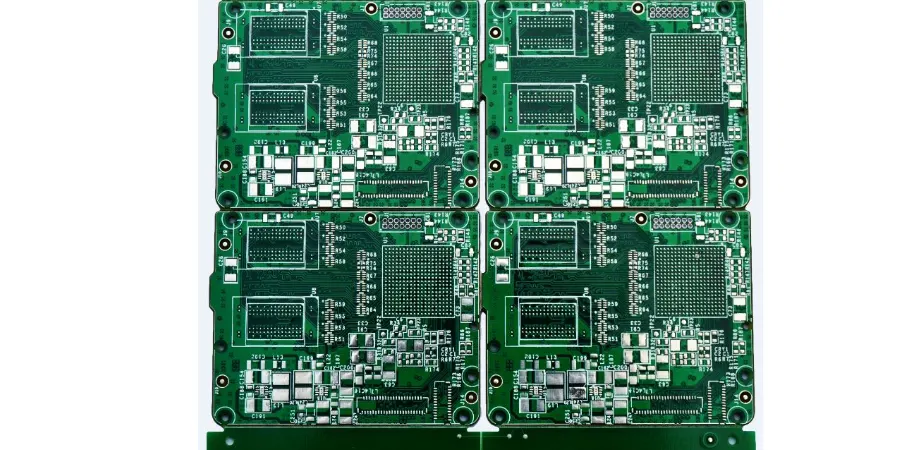

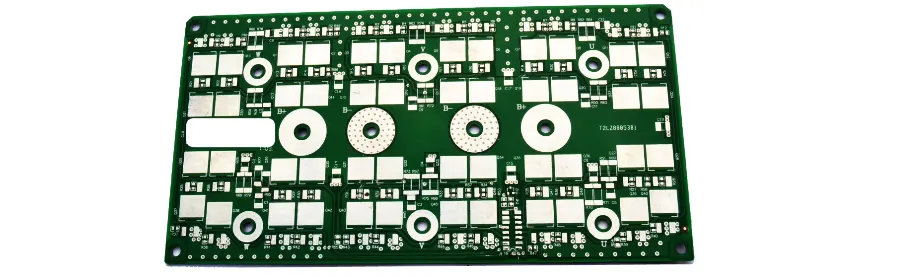

At Highleap PCB Factory (HILPCB), we specialize in high-quality PCB manufacturing and PCB assembly, focusing on spray tin and immersion gold surface finishes, as well as complex PCB processes. While Immersion Silver is a reliable option for various applications, our core expertise lies in providing cutting-edge solutions for demanding electronic designs, particularly for complex PCBs and high-frequency PCBs. We deliver a premium, tailored surface finish that ensures excellent solderability, high reliability, and compatibility with lead-free soldering processes, meeting the specific needs of industries ranging from consumer electronics to automotive systems.

What is Immersion Silver PCB?

Immersion Silver is a surface finish that involves depositing a thin layer of silver on the copper pads of a PCB. The process ensures a smooth, solderable surface that performs well in lead-free soldering processes. The thin silver layer (typically 0.1 to 0.5 microns) provides a reliable finish with low electrical resistance, ideal for high-frequency PCBs and high-density interconnects. It is often chosen for its affordability and eco-friendly benefits, as it eliminates the need for lead or other toxic materials.

Though immersion silver is a commonly used surface finish, at HILPCB, we focus more on immersion gold and spray tin finishes. These finishes offer unique advantages for specific applications, and we optimize these processes to meet the high-performance demands of modern electronics.

Benefits of Immersion Silver PCB

Immersion Silver is widely known for its benefits in applications requiring low resistance, excellent solderability, and a clean finish. Here are some of the advantages:

1. Superior Solderability

Immersion Silver provides a clean and smooth surface, making it ideal for soldering, especially with lead-free soldering processes. It ensures high-quality solder joints, even for fine-pitch components, making it suitable for multilayer PCBs and high-density assemblies.

2. High Electrical Performance

The silver layer in Immersion Silver PCBs offers excellent conductivity and low electrical resistance, making it an excellent choice for high-frequency and high-speed applications. The low impedance characteristics ensure the stability and reliability of signal transmission in RF circuits and digital systems.

3. Cost-Effectiveness

Compared to finishes like ENIG, Immersion Silver offers a cost-effective solution for high-volume production. The process is simpler and involves fewer materials, making it suitable for mass production of PCBs that don’t require the additional durability of gold or palladium layers.

4. Environmental Benefits

As a RoHS-compliant finish, Immersion Silver is free from lead and other hazardous materials, making it an environmentally sustainable solution for modern PCB manufacturing. This eco-friendly property is especially beneficial for industries that require compliance with international environmental standards.

5. Extended Shelf Life

Immersion Silver provides excellent shelf life stability. The silver coating maintains its solderability even after extended storage periods, ensuring the PCB remains ready for assembly without degradation of the surface finish.

Applications of Immersion Silver PCBs

Immersion Silver is used in various applications where excellent solderability and high electrical performance are required. Some common use cases include:

- Consumer Electronics: Immersion Silver PCBs are ideal for smartphones, wearables, and other consumer devices, where high solderability and electrical reliability are essential.

- Automotive Electronics: Automotive systems such as sensors, control units, and ECUs rely on Immersion Silver PCBs for durable, high-performance connections in challenging environments.

- Telecommunications: The excellent conductivity and minimal signal loss make Immersion Silver an ideal choice for high-frequency PCBs used in communication devices, satellite systems, and RF circuits.

- Medical Devices: In medical electronics, where reliability is paramount, Immersion Silver PCBs ensure stable and accurate performance in critical applications.

- High-Speed Digital Systems: In high-speed PCBs, especially those involving high-frequency signals and dense interconnections, Immersion Silver maintains superior performance without signal degradation.

Comparing Immersion Silver to Other Surface Finishes

While Immersion Silver provides excellent solderability and conductivity, it is important to compare it with other surface finishes, such as ENIG and HASL, to understand where it excels and where it might fall short.

Immersion Silver vs ENIG: ENIG is preferred for its superior durability, especially in applications requiring long-term reliability in harsh environments. However, Immersion Silver is a more cost-effective solution for medium-complexity PCBs where high-frequency performance and excellent solderability are the priorities.

Immersion Silver vs HASL: While HASL is known for being affordable and durable, it tends to have uneven surface topography, which can cause issues in fine-pitch components. Immersion Silver offers a smoother surface, making it ideal for high-density interconnects and fine-pitch applications.

Why Choose Highleap PCB Factory for Immersion Silver PCBs?

At Highleap PCB Factory (HILPCB), we offer high-quality Immersion Silver PCBs as part of our comprehensive PCB manufacturing services. While we primarily specialize in spray tin and immersion gold finishes, we ensure that all our processes, including Immersion Silver, meet the highest industry standards. Whether you need high-speed PCBs for advanced telecommunications systems or multilayer PCBs for complex designs, we provide tailored solutions to meet your unique project needs.

Our expertise in complex PCB processes ensures that you receive a product optimized for performance, durability, and cost-effectiveness. In addition to turnkey assembly, we provide detailed support for every aspect of PCB manufacturing, from design consultation to final testing.

For more information, explore our other products, such as ceramic PCBs, rigid-flex PCBs, and IC substrate PCBs.

FAQ

What makes Immersion Silver different from other finishes like ENIG?

Immersion Silver is a more cost-effective solution compared to ENIG. While ENIG provides higher durability, Immersion Silver offers excellent solderability and high electrical performance for medium-complexity designs.

How does Immersion Silver compare to HASL?

While HASL is an affordable and durable option, Immersion Silver provides better solderability and a smoother finish, making it ideal for fine-pitch components and high-frequency applications.

What industries use Immersion Silver PCBs?

Immersion Silver PCBs are widely used in consumer electronics, automotive electronics, medical devices, and communication systems, where high solderability and excellent electrical performance are required.

Is Immersion Silver suitable for multiple reflow cycles? Immersion Silver performs well in standard reflow processes, but it is less durable than ENIG under repeated thermal cycling. For high-reliability applications requiring multiple reflows, ENIG may be a better choice.

How should Immersion Silver PCBs be stored to prevent tarnishing? They should be stored in a dry, temperature-controlled environment with minimal exposure to air and light. Vacuum-sealed packaging is recommended to reduce oxidation and maintain solderability.

Can Immersion Silver PCBs be used for press-fit connector applications? Immersion Silver is not ideal for press-fit or high-friction mechanical connections due to its softer surface. ENIG or thicker surface finishes are more suitable in such cases.