Highleap PCB Factory (HILPCB) provides comprehensive PCB manufacturing and assembly solutions with advanced impedance testing capabilities. Our expertise spans from Time Domain Reflectometry (TDR) measurement systems to differential impedance validation technologies, ensuring optimal signal integrity that detects impedance variations, manufacturing defects, and transmission line issues before final product integration across diverse electronic applications.

Core Impedance Testing Technologies and Measurement Capabilities

Impedance testing represents the most critical quality control checkpoint in modern PCB manufacturing operations, providing comprehensive verification of transmission line characteristics, manufacturing consistency, and electrical performance through sophisticated measurement technologies and automated test sequences.

Advanced Impedance Testing Technologies:

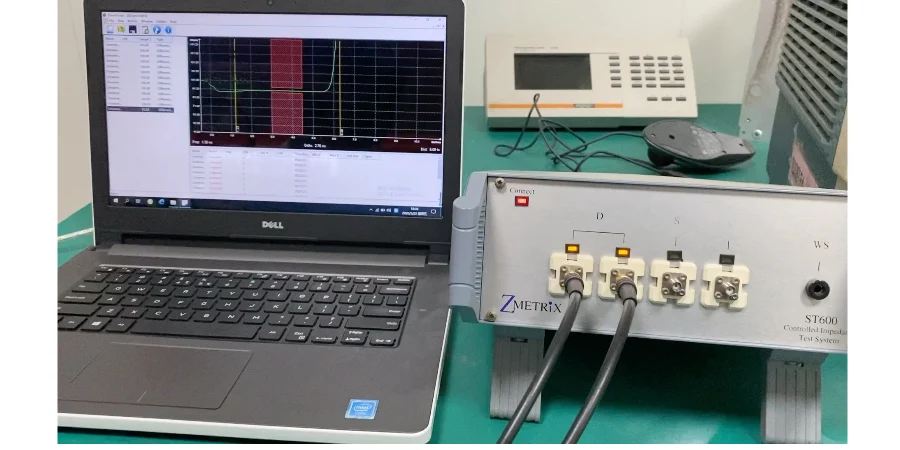

- Time Domain Reflectometry (TDR): High-resolution impedance profiling using sub-50 picosecond rise times for precise discontinuity detection

- Measurement Accuracy: Up to ±1% impedance accuracy from 10Ω to 150Ω with ±0.5% repeatability across temperature ranges

- Vector Network Analysis: Frequency-domain characterization enabling broadband impedance verification from DC to 40 GHz

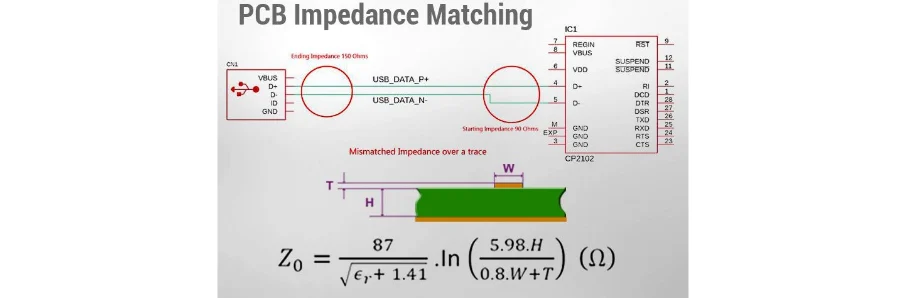

- Differential Impedance Testing: Specialized measurement techniques for coupled transmission lines with odd/even mode characterization

- Automated Test Systems: High-throughput production testing with integrated data management and statistical process control

- Coupon-Based Validation: Strategic test structure placement enabling continuous process monitoring without sacrificing product area

- Material Characterization: Dielectric constant and loss tangent measurement supporting accurate impedance prediction and correlation

- Environmental Compensation: Temperature and humidity correction algorithms maintaining measurement accuracy across production conditions

- Multi-Point Calibration: Comprehensive calibration procedures using precision standards ensuring measurement traceability

Strategic Impedance Implementation: Modern impedance testing platforms combine multiple measurement technologies enabling comprehensive defect detection while optimizing test execution time. Our China PCB manufacturing expertise ensures optimal impedance testing integration tailored to your specific quality requirements and production throughput demands.

Impedance Testing Implementation Strategies and Methodology Selection

Effective impedance testing program development requires strategic methodology selection based on production volume, board complexity, and quality specifications to maximize defect detection while maintaining cost-effectiveness and production throughput.

Production Volume and Methodology Matching: High-volume production environments benefit from automated impedance testing systems providing rapid test execution with excellent repeatability through dedicated test fixtures. These systems excel in standardized production scenarios where consistent board configurations enable fixture optimization and automated handling integration. Low-volume and prototype applications utilize manual TDR systems offering superior flexibility without custom fixturing requirements, enabling access to virtually any exposed conductor while accommodating frequent design changes and varied board configurations.

Complex Assembly Test Approaches: High-speed PCB assemblies require specialized impedance testing strategies addressing controlled impedance requirements and signal integrity concerns. Hybrid test methodologies combine automated coupon testing with selective board verification, maximizing test coverage while managing complexity. For multilayer PCB designs, comprehensive impedance testing programs verify transmission line consistency through multiple layers where visual inspection methods prove inadequate.

Test Coverage Optimization: Effective impedance testing programs balance comprehensive defect detection against execution time constraints through strategic test point placement and measurement prioritization. Critical transmission line verification focuses on high-speed differential pairs and single-ended controlled impedance traces, while production monitoring emphasizes process stability through coupon measurements. Statistical analysis of historical defect data guides test coverage decisions, ensuring resources focus on areas with highest quality impact while maintaining cost-effectiveness.

Manufacturing Process Integration and Quality Control Systems

Impedance testing integration within comprehensive quality management systems enables statistical process control, defect trend analysis, and continuous improvement initiatives that enhance manufacturing efficiency while maintaining consistent product quality standards.

Key Impedance Testing Control Elements:

• Equipment Calibration: Daily verification procedures using traceable standards ensure measurement accuracy within specification tolerances • Environmental Control: Maintain temperature stability within ±2°C preventing measurement drift. Implement humidity control and ESD protection measures safeguarding sensitive equipment • Test Program Validation: Comprehensive verification using known-good and defective boards confirming defect detection capability • Statistical Process Control: Real-time monitoring of test parameters with automated alerts for process drift detection • Defect Classification: Systematic categorization of failures enabling root cause analysis and process improvement targeting • Correlation Analysis: Comparison between impedance testing results and downstream functional test validating test program effectiveness • Data Management: Comprehensive recording and analysis of test results supporting traceability and quality documentation requirements • Equipment Maintenance: Preventive maintenance schedules and calibration protocols maintaining measurement integrity over time • Impedance calculator Integration: Design rule verification preventing testability issues during PCB development phases

Test Program Development and Optimization Techniques

Automated Test Generation and Development Tools

Modern impedance testing platforms provide sophisticated development environments enabling rapid test program creation through automated CAD data analysis and component libraries. These systems generate initial test sequences based on netlist analysis, component placement data, and predefined measurement parameters, significantly reducing development time while ensuring comprehensive coverage. Advanced development tools incorporate simulation capabilities allowing test program validation before implementation, identifying potential issues and optimizing measurement sequences for maximum efficiency.

Measurement Optimization and Parametric Testing

Effective impedance testing programs employ intelligent measurement strategies adapting to transmission line characteristics and circuit topology. Parametric testing focuses on verifying impedance values within specified tolerances while detecting subtle variations indicating manufacturing issues or material property deviations. Advanced algorithms optimize measurement sequences, minimize switching overhead, and employ parallel test techniques where possible, reducing overall test execution time while maintaining measurement accuracy and defect detection capability.

Debug Capabilities and Diagnostics

Comprehensive impedance testing systems provide detailed diagnostic information enabling rapid fault isolation and repair guidance. When defects are detected, advanced systems offer transmission line analysis, suggest probable causes, and recommend corrective actions based on failure analysis databases. This diagnostic capability proves particularly valuable for HDI PCB operations where rapid defect resolution maintains production flow and minimizes rework costs.

Controlled Impedance PCB Manufacturing with Integrated Testing at HILPCB

HILPCB, a leading PCB manufacturer in China, specializes in controlled impedance PCBs with impedance testing embedded throughout the production lifecycle. From design through final validation, our process ensures every board meets stringent signal integrity requirements.

Integrated Manufacturing and Testing We combine precision fabrication with in-line impedance verification at key stages. During lamination, dielectric thickness and material consistency are monitored; during etching, AOI systems validate trace geometries alongside impedance test coupons. This integration minimizes rework and ensures consistent, specification-compliant impedance.

Material Selection and Process Control Achieving accurate impedance starts with material selection. Our engineering team collaborates with customers to define stack-ups, trace widths, and materials based on dielectric constants, loss factors, and thickness tolerances. Backed by proprietary calculation tools and material databases, we ensure first-pass success without excessive iteration.

Built-in Quality Assurance Impedance testing is embedded within our ISO 9001-certified process—not an afterthought. Strategically placed coupons undergo automated TDR testing, with results feeding statistical process control. This proactive approach maintains tight tolerances, supports yield stability, and reduces cost.

With fully integrated impedance control, HILPCB delivers high-reliability PCBs that meet performance targets—on time and on spec.

PCB Impedance Testing – FAQ

What types of impedance variations can PCB testing detect? Impedance testing identifies transmission line discontinuities, PCB material deviations, manufacturing tolerances, and geometric inconsistencies. Advanced systems detect variations as small as ±1Ω in controlled impedance traces.

How does impedance testing compare to other signal integrity methods? Unlike simulations, which predict behavior, impedance testing directly measures actual PCB characteristics. It enables real-time process feedback and complements functional testing in comprehensive quality programs.

What affects PCB impedance test program development time? Development time depends on PCB complexity, number of controlled impedance traces, coverage requirements, and design data availability. Automation tools and libraries significantly reduce setup time.

Can impedance testing support fine-pitch and high-density PCBs? Yes. Modern systems use precision probes, optical alignment, and advanced fixturing to test dense PCB layouts and fine-pitch structures with sub-millimeter accuracy and reliability.

How do environmental conditions impact impedance measurement accuracy? Temperature, humidity, and vibration affect measurement stability. Professional test labs maintain ±2°C temperature control, humidity regulation, and vibration isolation, along with routine equipment calibration.

What quality standards apply to PCB impedance testing? Programs typically follow IPC-2221 (design), IPC-6012 (performance), and IPC-TM-650 (test methods), along with industry-specific standards for automotive, aerospace, and telecom applications.