Modern industrial systems rely on rugged and reliable electronics to control, monitor, and automate processes under extreme operating conditions. From factory floor automation to power electronics, industrial circuit boards play a foundational role in delivering stability, precision, and durability.

At Highleap PCB Factory, we support OEMs and system integrators with advanced PCB fabrication and assembly capabilities tailored for industrial applications. This article explores key design and manufacturing considerations for developing robust circuit boards suited to industrial environments.

What Are Industrial Circuit Boards?

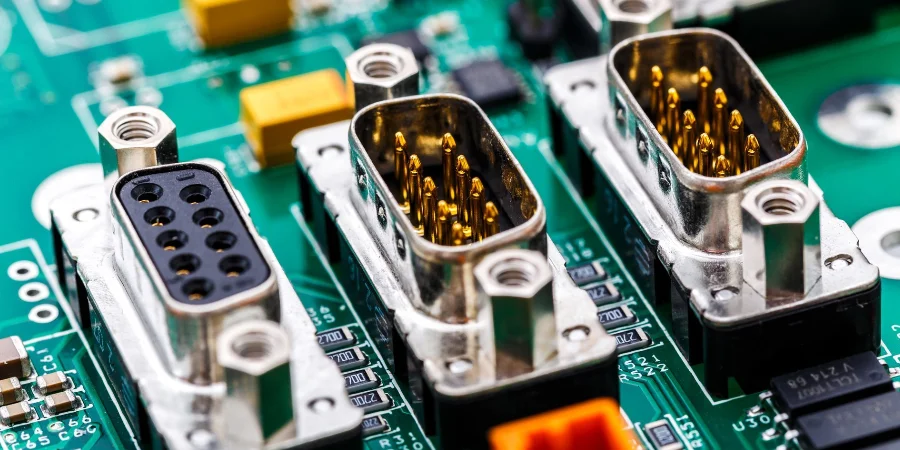

Industrial circuit boards are PCBs specifically designed to operate in high-stress environments such as temperature extremes, mechanical vibrations, electrical noise, and exposure to contaminants. These boards often serve in mission-critical roles across:

- Factory automation and robotics

- Motor drives and servo controllers

- Power conversion systems

- Industrial IoT (IIoT) sensors and gateways

- Programmable Logic Controllers (PLCs)

- Heavy machinery and process instrumentation

Compared to commercial-grade PCBs, industrial boards demand enhanced material selection, structural reinforcement, and manufacturing precision to maintain reliability and long service life.

Key Features of Industrial-Grade PCBs

1. Thermal Stability and High Tg Materials

Industrial environments often expose electronic components to sustained high temperatures. To ensure long-term reliability, industrial PCBs are typically built with high glass transition temperature (Tg) materials—such as FR-4 rated at ≥170 °C or polyimide substrates—that maintain structural and electrical stability under thermal stress.

2. Mechanical and Vibration Resistance

Applications like motor drives and mobile machinery subject circuit boards to continuous mechanical stress and vibration. Enhancing mechanical robustness through design techniques—such as using thicker copper (2 oz or more), edge plating, and reinforced through-holes—helps prevent fatigue-related failures and ensures structural integrity.

3. Protection from Moisture and Corrosive Agents

Industrial facilities often present harsh environmental factors such as moisture, chemical fumes, and airborne particulates. To safeguard circuitry, protective measures like conformal coatings and chemically resistant solder masks are applied to prevent oxidation, corrosion, and electrical shorts.

4. EMC Performance and Signal Integrity

Industrial systems frequently involve high-current switching and dense control logic, which can generate noise and signal degradation. Effective electromagnetic compatibility (EMC) begins with sound PCB layout: well-defined ground planes, optimized layer stack-ups, and clear separation between analog and digital domains help maintain signal integrity and system stability.

Design Guidelines for Industrial PCBs

Successful industrial PCB deployment starts at the design level. Consider the following best practices:

- Design for higher creepage and clearance distances to meet industrial safety standards (e.g., IEC 61010).

- Use thermal vias and heat spreaders to dissipate localized hot spots.

- Implement redundant grounding paths for safety and noise suppression.

- Apply design for manufacturability (DFM) principles to reduce production errors and improve testability.

- For high-voltage boards, simulate dielectric breakdown behavior and choose proper insulation material.

Manufacturing Considerations

Producing industrial PCBs requires more than standard fabrication workflows. Attention to the following factors is essential:

- Material consistency and traceability for long product life cycles

- Thick copper plating for power handling and mechanical durability

- Automated optical inspection (AOI) and in-circuit testing (ICT) to validate reliability

- Selective soldering for mixed SMD/THT assembly in hybrid systems

- IPC Class 2 or Class 3 compliance depending on application criticality

Highleap’s capabilities include multi-layer board construction, heavy copper up to 20 oz, impedance control, and rugged component mounting for harsh use cases.

Applications of Industrial PCBs

Industrial circuit boards power a vast range of systems where precision, uptime, and safety are paramount. Examples include:

- CNC and robotic controllers

- Power factor correction modules

- Sensor nodes and data acquisition systems

- Smart relays and programmable logic modules

- Energy monitoring and smart grid equipment

Extended Reliability and Lifecycle Considerations

Industrial PCBs are expected to operate reliably for 10 to 20 years in challenging environments. This requires selecting durable materials with high thermal and mechanical tolerance, and designing for solder joint stability and coating integrity under stress. Early-stage environmental validation—such as thermal cycling and vibration testing—is critical to confirming long-term resilience.

Designers must also plan for compliance with regional and industry standards like UL, CE, and RoHS. These requirements influence material selection, trace clearances, and fabrication processes. Ensuring consistent quality across production runs helps maintain traceability and minimizes failure risks in safety-critical systems.

To support maintainability and uptime, boards often include test points, modular connections, and basic diagnostic circuits. Increasingly, predictive maintenance features such as onboard sensors and microcontrollers are embedded to monitor real-time performance and enable proactive service in industrial automation systems.

Conclusion

Industrial circuit boards are the backbone of modern manufacturing, energy, and control systems. Designing and fabricating them requires deep understanding of application constraints, reliability requirements, and environmental stress factors.

Highleap PCB Factory combines precision fabrication, quality materials, and scalable assembly services to support industrial electronics across global markets. With a commitment to engineering excellence, we help ensure your industrial systems perform reliably in the most demanding conditions.