Highleap PCB Factory (HILPCB) specializes in manufacturing high-performance Isola PCBs utilizing the industry's most advanced laminate materials. Our expertise with Isola materials, combined with state-of-the-art manufacturing capabilities, delivers circuit boards that excel in demanding applications requiring superior electrical performance, thermal management, and long-term reliability.

Understanding Isola PCB Materials and Their Applications

Isola Group's advanced circuit materials represent the pinnacle of PCB substrate technology, engineered for applications where standard FR-4 PCB cannot meet performance requirements. Our Isola PCB manufacturing capabilities encompass the complete portfolio including:

High-Speed Digital Materials

- Isola FR408HR: The industry standard for high-speed digital applications, featuring Dk of 3.65 and Df of 0.0092 at 10 GHz

- Isola I-Speed: Ultra-low loss material with Df of 0.0031 at 10 GHz for 25+ Gbps applications

- Isola Tachyon-100G: Engineered specifically for 100G and beyond with exceptional signal integrity

Thermal Management Solutions

- Isola 370HR: Lead-free compatible with 180°C Tg and superior CAF resistance

- Isola P96: High thermal reliability material for automotive and aerospace applications

- Isola G200: Combines high Tg (200°C) with low CTE for extreme thermal cycling

These Isola laminate materials enable breakthrough performance in telecommunications infrastructure, high-performance computing, automotive radar, and aerospace avionics. Our engineering team leverages deep material knowledge to recommend optimal Isola solutions based on your specific electrical, thermal, and mechanical requirements.

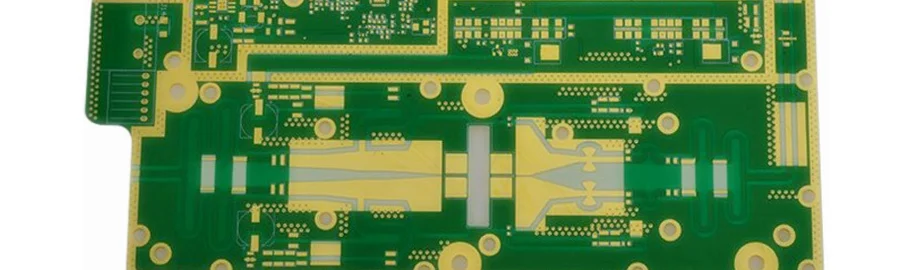

Advanced Manufacturing Processes for Isola Circuit Boards

Manufacturing Isola PCBs demands precise process control to preserve the exceptional properties of these advanced materials. Our facility maintains dedicated production lines for high-frequency Isola materials, preventing cross-contamination and ensuring consistent electrical performance. Critical process parameters include:

Lamination Optimization: Customized pressure and temperature profiles for each Isola material grade ensure complete resin flow without degrading electrical properties. Our vacuum-assisted lamination systems eliminate voids while maintaining uniform dielectric thickness essential for impedance control.

Drilling Technology: Isola's reinforced resin systems require specialized drill parameters to achieve clean hole walls. We utilize high-speed spindles with controlled feed rates and peck drilling cycles, followed by plasma desmear processes that remove resin without attacking the glass fabric.

Plating Chemistry: Our copper plating processes are optimized for Isola materials' unique surface characteristics, ensuring excellent adhesion and uniform thickness distribution. Specialized pre-treatment enhances copper bonding to smooth resin surfaces common in low-loss materials.

Isola PCB Solutions for High-Speed Applications

Signal Integrity Excellence

Modern digital systems operating at 25 Gbps and beyond demand exceptional signal integrity that only premium Isola materials can deliver. Our Isola FR408HR PCB manufacturing combines material excellence with precise impedance control, achieving ±5% tolerance on differential pairs. Advanced modeling using 3D electromagnetic simulation ensures first-pass success for complex channel designs.

Key capabilities for high-speed PCB with Isola materials include:

- Back-drilling to remove stub resonances

- Sequential lamination for optimal layer transitions

- Precision depth routing for edge-coupled structures

- Surface roughness control for skin effect management

Thermal Reliability for Lead-Free Assembly

Isola 370HR circuit boards excel in lead-free assembly environments where peak reflow temperatures exceed 260°C. The material's 180°C Tg provides margin against thermal degradation while low Z-axis CTE (50 ppm/°C) minimizes PTH stress. Our assembly lines feature profiled reflow zones optimized for Isola materials, preventing warpage while ensuring reliable solder joints.

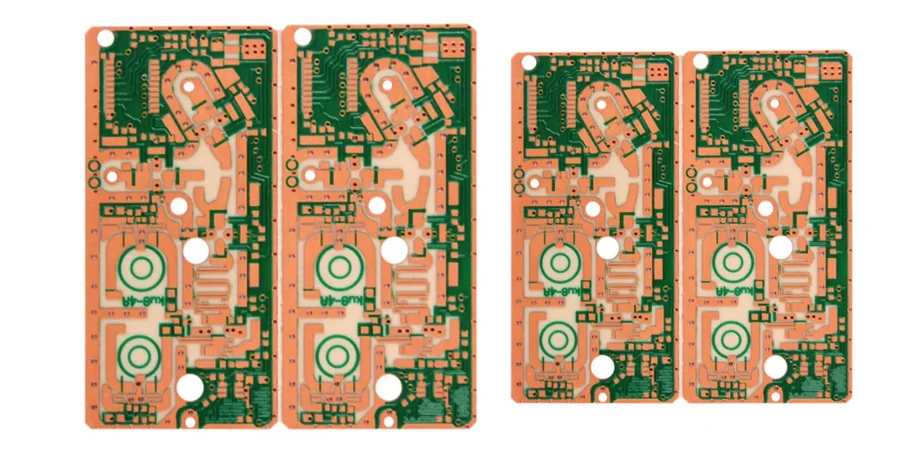

Comprehensive Isola PCB Manufacturing Capabilities

HILPCB processes over 20,000 square meters of Isola laminates monthly across diverse applications. Our capabilities span:

- Layer Count: 2-64 layers with sequential lamination

- Board Thickness: 0.2mm to 8.0mm

- Copper Weight: 0.5 oz to 10 oz

- Minimum Features: 2/2 mil trace/space, 0.1mm vias

- Surface Finishes: ENIG, Immersion Silver, OSP, Hard Gold

Quick-turn prototyping delivers Isola PCBs in 5-7 days for standard configurations, with 24-hour expedite available for urgent requirements. Volume production leverages panel optimization and automated handling to achieve competitive pricing without compromising quality.

Quality Assurance for Isola PCB Manufacturing

Every Isola circuit board undergoes comprehensive testing exceeding IPC-6012 Class 3 requirements:

Electrical Testing: 100% continuity and isolation verification using flying probe or bed-of-nails fixtures. Time Domain Reflectometry (TDR) confirms impedance control within specification.

Microsection Analysis: Cross-sectional examination verifies lamination quality, plating thickness, and registration accuracy. CAF resistance testing validates long-term reliability for Isola 370HR applications.

Material Certification: We maintain full traceability from raw material through finished product, providing certificates of conformance documenting material properties and test results.

Complete Isola PCB Assembly Services

Beyond bare board fabrication, HILPCB offers comprehensive turnkey assembly services optimized for Isola substrates. Our SMT assembly lines feature:

- Precision placement for 01005 components and 0.3mm pitch BGAs

- Vapor phase soldering for uniform heating of thick Isola boards

- X-ray inspection for hidden solder joints

- In-circuit and functional testing

Component sourcing leverages authorized distributors ensuring authentic parts for high-reliability applications. Our assembly processes accommodate the unique thermal characteristics of Isola materials, preventing warpage while achieving IPC-A-610 Class 2 and 3 requirements.

Global Logistics and Customer Support

HILPCB streamlines international delivery of Isola PCBs through established logistics partnerships. Our export team manages documentation including:

- Commercial invoices with harmonized tariff codes

- Certificates of origin for preferential duty treatment

- Material safety data sheets for regulatory compliance

- Quality certifications per customer requirements

Payment flexibility includes wire transfer, PayPal, credit cards, and letter of credit options. NET terms are available for qualified accounts with regular volume requirements.

Why Choose HILPCB for Isola PCB Manufacturing

Selecting the right manufacturer for Isola PCBs impacts product performance and project success. Our advantages include:

- Technical Expertise: Dedicated engineers experienced with all Isola material grades

- Rapid Prototyping: 24-48 hour quick-turn for standard configurations

- Volume Production: Capacity exceeding 50,000 sqm monthly

- Quality Systems: ISO 9001, IATF 16949, AS9100 certified

- Complete Solutions: From bare boards through assembled systems

- Global Support: 24/7 customer service in multiple languages

Partner with HILPCB for your next Isola PCB project and experience the difference of working with material specialists who understand the nuances of advanced laminates. Whether you need Isola FR408HR for high-speed digital, Isola 370HR for thermal reliability, or specialized high-frequency PCB materials for RF applications, we deliver exceptional quality on time and within budget.

FAQ

What are typical lead times for Isola PCB manufacturing?

Standard Isola PCB designs ship in 7-10 days, with 48-72 hour expedite available for prototypes. Complex builds with sequential lamination or back-drilling typically require 12-15 days. We stock common Isola materials to minimize procurement delays.

How do you ensure impedance control on Isola high-speed materials?

We utilize field solver modeling during design review to predict impedance values. Production controls include precise lamination pressure, copper plating thickness monitoring, and 100% TDR testing. Our standard tolerance is ±10% with ±5% available for critical applications. For help with calculations, try our impedance calculator.

Can you process both standard and halogen-free Isola materials?

Yes, we process both standard and halogen-free Isola grades including green materials like FR408HRIS and 370HRIS. Dedicated production lines prevent cross-contamination between material types.

What Isola materials do you recommend for automotive applications?

For automotive electronics, we typically recommend Isola 370HR for general applications and P96 or G200 for under-hood environments. These materials meet automotive reliability requirements including thermal cycling and vibration resistance.

Do you support hybrid stackups mixing Isola with other materials?

Yes, we manufacture hybrid constructions combining Isola materials with Rogers, Taconic, or standard FR-4 layers. This approach optimizes cost while placing high-performance materials only where needed for signal integrity or thermal management.

What design support do you provide for Isola PCB projects?

Our engineering team offers free DFM review, stackup recommendations, and impedance modeling. We can suggest alternative Isola materials that may better suit your application or reduce cost while meeting performance requirements.

How do you handle moisture sensitivity of Isola materials?

All Isola materials are stored in humidity-controlled environments and vacuum-sealed until use. We pre-bake materials according to manufacturer specifications and track exposure time to prevent moisture-related defects during assembly.

What certifications are available for Isola PCB manufacturing?

We provide full material traceability, IPC-6012 Class 2/3 compliance certificates, UL certification, and specific test reports including TDR data, microsections, and ionic contamination results. Custom testing and reporting are available upon request.