As a leading Kapton PCB manufacturer specializing in high-performance flexible circuits, we deliver precision-engineered solutions for aerospace, medical, automotive, and industrial applications. Our advanced manufacturing capabilities combined with DuPont Kapton polyimide materials ensure exceptional thermal stability, mechanical flexibility, and long-term reliability for your most demanding projects.

Understanding Kapton PCB Technology and Material Properties

Kapton polyimide film, developed by DuPont, represents the industry standard for high-performance flex PCB applications requiring extreme temperature resistance and mechanical durability. With continuous operating temperatures from -269°C to +400°C, Kapton PCBs maintain their electrical and mechanical properties in environments where conventional materials fail. The material's dielectric strength of 7,700 V/mil, combined with excellent chemical resistance and low outgassing properties, makes it ideal for space-qualified electronics and harsh industrial environments.

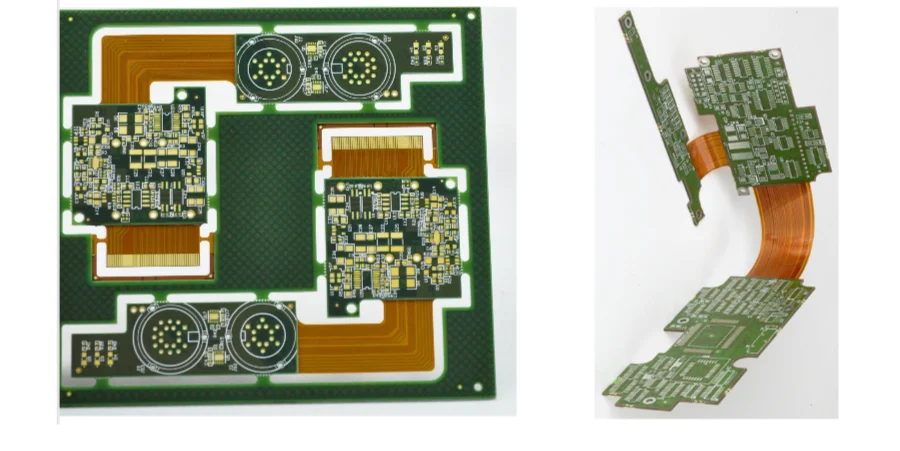

Our Kapton PCB manufacturing capabilities encompass single-sided, double-sided, and multilayer flexible circuits using various Kapton grades including HN, FN, and HPP-ST. We process adhesiveless copper-clad laminates (AP8525R, AP8535R) and adhesive-based systems, optimizing material selection based on your specific application requirements. The inherent dimensional stability of Kapton, with thermal expansion coefficients matching copper, ensures reliable performance through extreme thermal cycling.

Advanced Manufacturing Processes for Kapton Flexible Circuits

Kapton PCB fabrication requires specialized expertise to handle the unique properties of polyimide materials. Our state-of-the-art facility employs precision laser cutting for intricate outline profiling, achieving tolerances of ±0.025mm while preventing edge delamination. UV laser drilling creates microvias as small as 50 microns, enabling HDI PCB designs in flexible formats for high-density interconnect applications.

The metallization process for Kapton substrates utilizes plasma surface activation followed by electroless copper deposition specifically formulated for polyimide adhesion. Our controlled plating parameters ensure uniform copper distribution essential for impedance control and signal integrity. We achieve fine-line circuitry down to 2 mil trace/space using advanced photolithographic techniques optimized for flexible substrates, supporting high-frequency designs up to 40 GHz.

Kapton PCB Design Guidelines and Best Practices

| Design Feature | Recommended Specification | Our Capability |

|---|---|---|

| Minimum Trace Width | 0.003" (75 μm) | 0.002" (50 μm) |

| Minimum Via Size | 0.006" (150 μm) | 0.004" (100 μm) |

| Copper Weight | 0.5 oz - 2 oz | 0.5 oz - 3 oz |

| Bend Radius | 6x total thickness | 3x for dynamic flex |

| Coverlay Opening | +0.010" larger than pad | +0.005" achievable |

| Stiffener Materials | FR-4, Polyimide, Steel | All types available |

Key Applications for Kapton PCB Solutions

Aerospace and Satellite Systems

Kapton PCBs excel in satellite solar arrays, spacecraft wire harnesses, and avionics systems where weight reduction and reliability are critical. Our space-qualified Kapton circuits withstand radiation exposure, extreme temperature variations, and maintain performance in vacuum environments. We support NASA and ESA programs with full documentation and traceability.

Medical Device Innovation

The biocompatibility and flexibility of Kapton enable breakthrough medical devices including catheter-based sensors, implantable electronics, and wearable health monitors. Our ISO 13485 certified cleanroom assembly ensures contamination-free production for medical-grade Kapton PCBs used in MRI-compatible devices and minimally invasive surgical tools.

Automotive Electronics

Modern vehicles utilize Kapton flexible circuits in engine compartments, transmission controls, and LED lighting systems where high temperatures and vibration challenge conventional PCBs. Our automotive-grade Kapton PCBs meet IATF 16949 standards with proven reliability in under-hood applications exceeding 150°C.

Industrial and Energy Sectors

Oil and gas exploration equipment, solar panel interconnects, and industrial automation systems leverage Kapton's chemical resistance and thermal stability. We manufacture Kapton PCBs for downhole drilling tools operating at 200°C, photovoltaic cell interconnections, and robotics requiring millions of flex cycles.

Rapid Prototyping and High-Volume Kapton PCB Production

Understanding time-critical development cycles, our quick-turn Kapton PCB service delivers prototypes in 48-72 hours for standard single and double-sided designs. Rigid-flex PCB prototypes combining Kapton flexible sections with FR-4 rigid areas ship within 5-7 days. We maintain strategic inventory of common Kapton materials to eliminate procurement delays and accelerate your product launch.

Production volumes scale seamlessly from prototype to millions of units annually. Our automated handling systems designed for flexible materials ensure consistent quality while optimizing costs. Standard production lead times range from 7-10 days with expedite options available. We utilize advanced nesting software to maximize material utilization, passing cost savings to our customers while maintaining superior quality standards.

Quality Assurance and Reliability Testing for Kapton PCBs

Every Kapton PCB undergoes comprehensive inspection exceeding IPC-6013 Class 3 requirements for flexible printed boards. Our quality protocols include:

- 100% Electrical Testing: Automated flying probe or bed-of-nails fixtures verify connectivity and isolation

- Dimensional Inspection: Vision systems confirm critical dimensions within ±0.001" accuracy

- Flexibility Testing: Dynamic bend testing validates performance through specified flex cycles

- Peel Strength Verification: Ensures copper adhesion exceeds 8 lb/inch for long-term reliability

- Thermal Stress Screening: Validates performance through -55°C to +150°C temperature cycling

- Impedance Control: TDR measurements confirm ±10% tolerance for controlled impedance designs

- Cleanliness Testing: Ionic contamination analysis ensures reliability in harsh environments

Our 3D viewer tool allows you to visualize your Kapton PCB design before production, ensuring accurate mechanical fit in your assembly.

Your Trusted Kapton PCB Manufacturer and Assembly Partner

Beyond Kapton PCB fabrication, we provide complete turnkey assembly services including component sourcing, SMT placement, and functional testing. Our specialized fixtures accommodate flexible and rigid-flex assemblies while maintaining precise component alignment. We handle fine-pitch BGAs, 01005 components, and specialized connectors with ±25 micron placement accuracy.

Global logistics capabilities ensure timely delivery through partnerships with DHL, FedEx, and UPS. We offer temperature-controlled shipping for sensitive assemblies and expedited customs clearance for international orders. Payment options include PayPal, wire transfer, credit cards, and NET terms for qualified customers. Our secure online portal provides instant quotes, order tracking, and direct engineering support.

Partner with a Kapton PCB manufacturer committed to your success. Our experienced engineering team provides free design reviews, material selection guidance, and ongoing technical support. Whether you need quick-turn Kapton prototypes, volume production, or complete SMT assembly, we deliver quality products on time and within budget. Contact us today to discuss your Kapton PCB requirements and experience the advantage of working with flexible circuit experts.