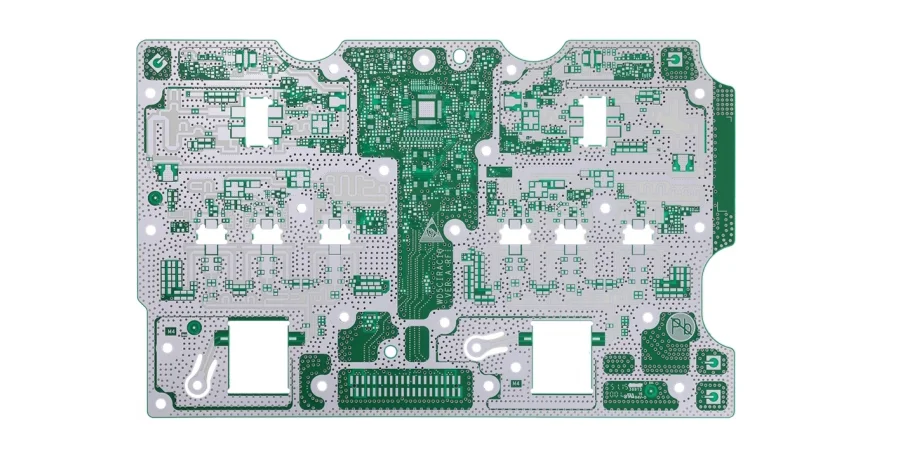

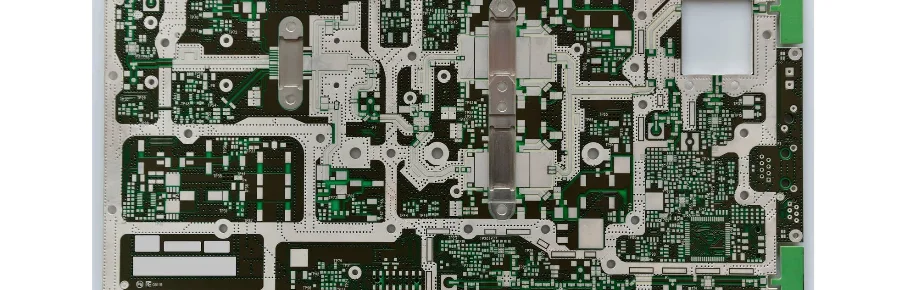

Lead-Free HASL PCB Manufacturing Solutions

At HILPCB, we offer a wide range of PCB manufacturing solutions, including lead-free HASL surface finishes to meet global environmental and performance standards. Our processes ensure excellent solderability, enhanced shelf life, and reliable performance across diverse industries, ensuring that all our products meet RoHS compliance without compromising on quality.

Why Choose Lead-Free HASL?

Lead-free HASL is an ideal solution for meeting global environmental standards without sacrificing performance. Compared to traditional tin-lead coatings, it offers better mechanical strength and higher temperature reliability, making it a perfect choice for electronics that undergo thermal cycling or have high-frequency operation. Despite being a cost-effective solution, SAC305 still ensures excellent wetting characteristics and extended shelf life, making it a reliable option for various PCB applications, especially through-hole and mixed-technology assemblies.

Furthermore, lead-free HASL aligns with the growing demand for sustainable electronics in today’s global market. As environmental regulations continue to tighten, particularly in regions like Europe and North America, adopting lead-free solutions not only ensures compliance but also enhances a product’s marketability. The RoHS compliance of lead-free HASL makes it a future-proof choice, enabling companies to meet regulatory requirements while avoiding the potential costs and delays associated with non-compliant materials.

By choosing lead-free HASL, you’re investing in a cleaner, safer, and more reliable technology, without compromising on the quality and durability of your PCBs. This combination of environmental responsibility and performance optimization makes lead-free HASL an essential part of any modern PCB manufacturing strategy.

Process Optimization for Lead-Free HASL Applications

Manufacturing lead-free HASL PCBs demands precise process control exceeding traditional HASL requirements. The higher processing temperatures and different wetting characteristics necessitate equipment modifications and parameter optimization.

Temperature Profile Management

Pre-heating becomes critical with lead-free HASL's elevated temperatures. Boards require gradual heating to 140-160°C before solder immersion, compared to 100-120°C for leaded processes. This extended pre-heat prevents thermal shock while ensuring uniform temperature distribution across multilayer PCB stackups. Infrared heating zones with forced convection provide optimal heat transfer without oxidizing exposed copper.

Solder Bath Maintenance

Lead-free solder pots operate at 265-275°C, stressing equipment components and accelerating copper dissolution. Maintaining copper content below 0.3% prevents sluggish wetting and dewetting defects. Iron contamination from equipment wear must stay under 0.02% to avoid gritty textures. Our automated monitoring systems track bath composition hourly, with daily lab analysis ensuring consistent alloy properties.

Air Knife Optimization

Higher surface tension of lead-free alloys requires increased air knife pressure (25-35 PSI) and optimized angles (50-70°) for effective leveling. Knife positioning closer to the solder surface (15-20mm) improves thickness control but demands precise alignment. Variable frequency drives on withdrawal motors enable speed optimization (20-40 inches/minute) based on board characteristics.

Post-Process Cooling

Controlled cooling prevents thermal stress and optimizes microstructure. Forced air cooling zones gradually reduce temperature from 260°C to 100°C over 60-90 seconds, followed by ambient cooling. This profile minimizes residual stress while promoting fine-grained solder structure. Water quenching, sometimes used for leaded HASL, risks thermal shock with lead-free alloys and should be avoided.

Comparative Analysis: Lead-Free vs Traditional HASL

Understanding performance differences between lead-free and leaded HASL enables informed selection based on application requirements beyond regulatory compliance.

Mechanical Properties Lead-free HASL exhibits 40% higher tensile strength but reduced elongation compared to SnPb coatings. This translates to better load-bearing capacity but increased susceptibility to thermal fatigue cracking. Drop shock performance improves 20-30% due to higher strength, benefiting portable electronics. However, applications experiencing extreme thermal cycling may see reduced lifetime.

Wetting Characteristics Lead-free alloys demonstrate slower wetting kinetics, requiring 0.5-1.0 seconds longer to achieve comparable spreading. Contact angles measure 15-20° higher, creating thicker coatings at confined geometries. This characteristic complicates fine-pitch assembly but provides better protection for through-hole components and connectors.

Shelf Life Performance Oxidation rates remain comparable between finish types when properly processed. Lead-free HASL PCBs maintain solderability exceeding 12 months in controlled storage, with minimal degradation up to 24 months. The thicker oxide layer on lead-free surfaces actually provides better environmental protection once formed, though it requires slightly more aggressive flux during assembly.

Cost Implications Raw material costs for SAC305 exceed SnPb by 3-4x due to silver content. Higher processing temperatures increase energy consumption 15-20%. Equipment wear accelerates, requiring more frequent maintenance. Overall, lead-free HASL costs 20-30% more than traditional HASL but remains the most economical RoHS-compliant finish for many applications.

Design Considerations for Lead-Free HASL PCB Success

Optimizing PCB designs for lead-free HASL processing ensures manufacturing success and assembly reliability.

Thermal Management Strategies

Higher processing temperatures demand careful attention to substrate selection and copper balance. Standard FR-4 PCB materials withstand lead-free HASL temperatures, but marginal Tg materials risk delamination. Copper distribution should maintain <30% variation across layers to prevent warpage. Incorporating copper thieving in sparse areas helps balance thermal mass during processing.

Component Footprint Optimization

Lead-free HASL's increased thickness variation requires adjusted land patterns. BGA pads benefit from 5-10% diameter reduction compared to ENIG designs. QFP lands should extend 0.1mm beyond nominal to accommodate coating thickness. Fine-pitch components (<0.5mm) may require selective finishing or solder paste volume adjustments during assembly.

Via and Hole Considerations

Through-hole filling characteristics differ with lead-free alloys. Vias >0.5mm diameter may retain excess solder requiring design modifications. Implementing tenting for vias <0.3mm prevents solder wicking. Aspect ratios exceeding 8:1 challenge uniform coating distribution, particularly for HDI PCB designs with microvias.

Panel Array Configuration

Board orientation during processing significantly impacts coating uniformity. Arranging smaller boards with consistent spacing (3-5mm) promotes even heating and cooling. Rail widths should exceed 5mm to provide adequate support during high-temperature exposure. Breaking tabs require 0.8-1.0mm thickness to survive thermal stress without cracking.

Quality Assurance and Reliability Testing Protocols

HILPCB implements comprehensive quality systems validating lead-free HASL performance for demanding applications.

Incoming Material Verification

- Solder alloy certification confirming SAC305 composition ±0.1%

- PCB substrate Tg testing ensuring >140°C rating

- Copper foil adhesion verification exceeding 1.4 N/mm

Process Control Monitoring

- Real-time temperature logging across pre-heat and solder zones

- Air knife pressure monitoring with ±1 PSI accuracy

- Coating thickness measurement at 5 locations per board

- Visual inspection for dewetting, non-wetting, or exposed copper

Solderability Validation

- IPC J-STD-003 wetting balance testing

- Steam aging 8 hours at 93±2°C

- Confirmation of >75% wetting force within 1 second

- Cross-section analysis verifying IMC thickness 2-6μm

Environmental Testing

- Thermal cycling -40°C to +125°C for 1000 cycles

- 85°C/85% RH exposure for 1000 hours

- Mixed flowing gas testing for harsh environments

- Mechanical shock and vibration per application standards

Our turnkey assembly services include comprehensive testing ensuring lead-free HASL boards meet all performance requirements.

FAQ

What are the main advantages of lead-free HASL over traditional HASL? Lead-free HASL provides RoHS compliance essential for global markets while offering superior mechanical strength and high-temperature reliability. The finish exhibits better drop shock resistance and maintains stable IMC growth. Environmental benefits include eliminated lead exposure during manufacturing and recycling.

How does lead-free HASL compare to other RoHS-compliant finishes? Lead-free HASL costs 40-60% less than ENIG while providing superior shelf life versus OSP. Unlike immersion silver, it withstands multiple assembly cycles without degradation. The finish excels for through-hole assembly and mixed-technology boards where other finishes show limitations.

What design modifications are needed for lead-free HASL? Adjust BGA pad sizes 5-10% smaller than ENIG specifications. Ensure substrate Tg exceeds 140°C with 20°C safety margin. Balance copper distribution maintaining <30% variation between layers. For fine-pitch components below 0.5mm, consider selective finishing combining lead-free HASL with ENIG.

Can existing HASL equipment process lead-free alloys? Most HASL equipment accommodates lead-free processing with modifications. Heating elements require upgrading for 275°C operation. Solder pots need titanium or cast iron construction resisting erosion. Air knife systems benefit from variable pressure controls handling increased surface tension.

What storage conditions optimize lead-free HASL shelf life? Store boards in moisture-barrier bags with desiccant maintaining <30% relative humidity. Temperature should remain between 10-30°C avoiding condensation. Proper storage extends solderability beyond 24 months. Unlike moisture-sensitive finishes, lead-free HASL tolerates temporary exposure during handling.

How do I specify lead-free HASL in design documentation? Specify "Lead-free HASL per IPC-4552" or "SAC305 HASL, RoHS compliant" in fabrication notes. Include acceptability criteria referencing IPC-A-610 Class 2 or 3. Our Gerber viewer helps verify surface finish callouts ensuring clear communication of requirements.