The foundation of any high-performance lighting product is the LED PCB—a thermally managed, electrically stable circuit board that ensures your LEDs operate reliably. At Highleap PCB Factory, we provide custom LED PCB manufacturing, aluminum-core board fabrication, and complete LED PCB assembly with integrated LED enclosure design. From household luminaires to IP-rated industrial floodlights, our end-to-end services offer consistency, quality, and production scalability.

1. Understanding LED PCBs: Materials, Core Types & Use Cases

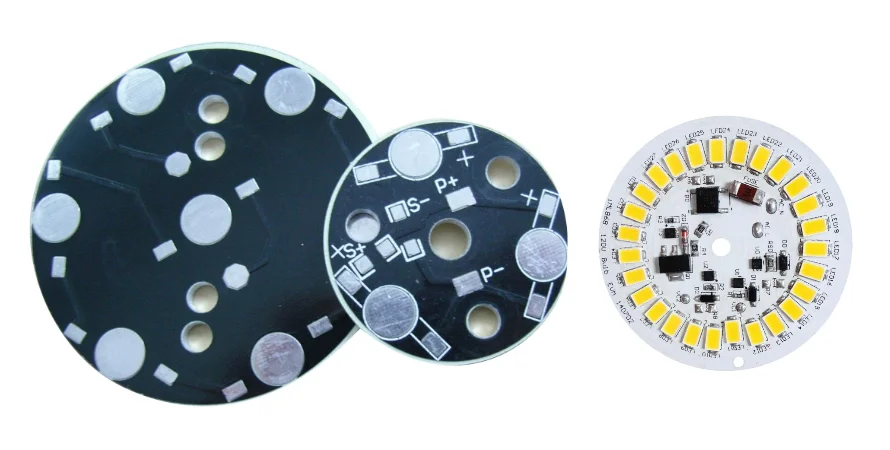

An LED circuit board is a printed board designed to power and cool light-emitting diodes efficiently. In contrast to traditional FR4 PCBs, metal-core LED PCBs integrate thermally conductive substrates—most often aluminum—to draw heat away from the diode junction and dissipate it via the housing or enclosure.

Types of LED PCBs we manufacture:

- Aluminum LED PCBs for general lighting and consumer products

- Copper-core LED PCBs for high-power or automotive systems

- Hybrid LED PCBs with FR4 logic layers + MCPCB power layers

- Flexible LED PCBs for curved or dynamic form factors

Typical applications:

- Smart home LED panels

- Solar floodlights and outdoor luminaires

- Automotive tail lights and DRLs

- High-bay industrial fixtures

- LED strips for signage and commercial interiors

We support both prototype LED boards and bulk LED PCB manufacturing for domestic and international clients.

2. Thermal Design, Layout & Tooling Best Practices

A successful LED PCB design requires not just electronic function, but thermal, mechanical, and optical precision. Whether you're ordering 10 panels or 10,000, these layout and design guidelines apply:

- Component Spacing: Allow thermal buffer zones for LED clusters and avoid shadowing between diodes.

- Copper Sizing: Use wide power traces and copper pours; high current LED strings need lower resistance paths.

- Thermal Vias: Add vertical paths under LEDs and regulators to transfer heat into the aluminum substrate.

- Reflective Coatings: White ENIG or OSP masks enhance lumen output by up to 20%.

- Panelization Strategy: Use V-cuts or break-tabs to improve assembly yield in mass LED PCB production.

Want to validate your layout? Use our free Gerber Viewer to inspect trace placement, copper distribution, and drill alignment. You can also explore final board geometry using the 3D Viewer to simulate enclosure fitting.

3. LED PCB Assembly, Quality Assurance & Integrated Enclosures

Highleap’s LED PCB assembly process is engineered for automated precision and consistency across every batch:

- SMT LED mounting with controlled paste application and reflow profile tuning

- Wave soldering for mixed technology boards with through-hole drivers

- Functional testing for electrical current handling and light uniformity

- X-ray and AOI inspection for BGA and fine-pitch assemblies

- Color bin matching to ensure consistent CCT across production runs

We also support full LED module integration, offering:

- CNC-machined aluminum enclosures with IP65+ sealing

- Thermally optimized mounting frames and mechanical brackets

- Optical lenses, diffuser plate fitting, and full unit prototyping

Our tooling teams ensure your LED PCB enclosure aligns with production-ready form factors and cooling strategies.

4. Bulk LED PCB Manufacturing for Industrial & Commercial Projects

Whether you're producing streetlamps or indoor strips, LED PCB mass production depends on tight process control and repeatable material quality:

- Base Materials: Aluminum-core thicknesses from 1.0 to 3.2 mm; copper up to 3 oz

- Surface Finishes: ENIG, white HASL, OSP—selected for reflectivity and corrosion resistance

- Panel Sizes: Up to 600 mm wide, supporting large-area LED modules

- Panel Design: Precision V-grooving, break-routes, and multi-up layouts

- Optical Testing: Brightness consistency, CRI validation, and thermal cycling

We deliver large-scale LED PCBs to OEMs in lighting, automotive, signage, and energy industries—with support from prototype to full-scale production.

5. Why Engineers Choose Highleap for LED PCB Projects

- Expert China LED PCB manufacturing with engineering-first approach

- Smooth scale from R&D to large-volume LED PCB orders

- In-house enclosure integration + assembly verification

- Tools like Gerber Viewer and 3D Viewer for early DFM

- Competitive lead times, bilingual support, and ISO-certified processes

Ready for a Custom LED PCB Quote?

Highleap offers LED PCB fabrication, metal-core LED PCB production, and LED circuit board assembly—plus the enclosure integration that lighting products demand. We build for:

- Bulk lighting deployments

- OEM component supply

- ODM full module design

Reach out to Highleap PCB Factory to get started with a quote or free DFM review on your LED PCB project.