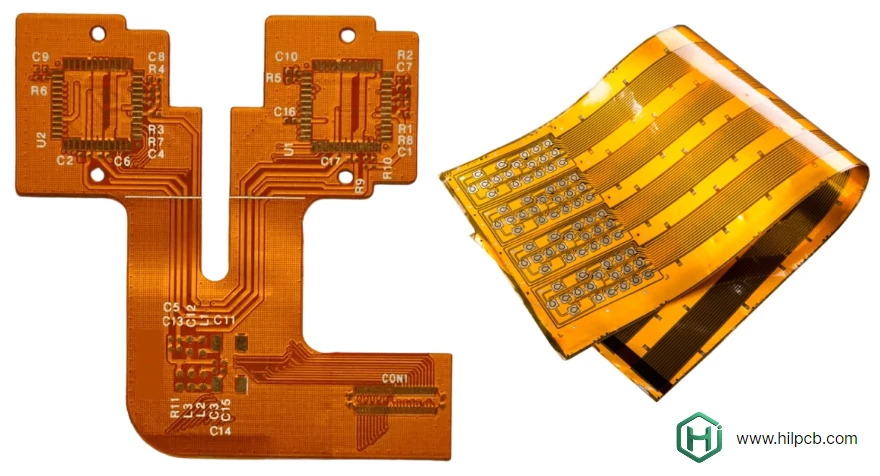

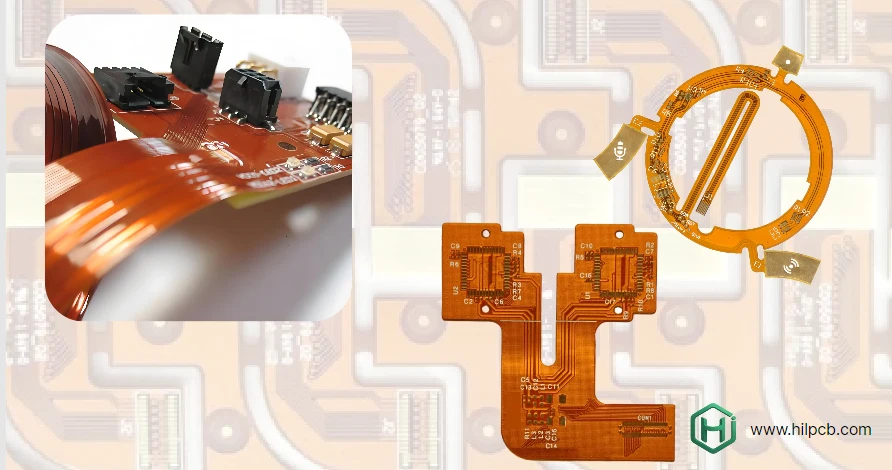

Engineers designing compact, high-performance electronics often face a trade-off between routing density and flexibility. Multilayer flex PCB manufacturing bridges this gap — allowing complex interconnections within ultra-thin, bendable structures.

As a leading multilayer flex PCB manufacturer in China, HILPCB delivers precision-engineered flexible circuits for aerospace, automotive, medical, and consumer applications. Our fabrication technology supports 4 to 16 layers, controlled impedance, and fine-line copper routing while maintaining mechanical flexibility and superior reliability.

What Is a Multilayer Flex PCB and How It Works

A multilayer flexible circuit board consists of three or more conductive copper layers separated by flexible dielectric films such as polyimide. These layers are interconnected by via holes (through, blind, or buried) and laminated to achieve both circuit density and flexibility.

Compared with double layer flex PCB, multilayer flex PCBs offer:

- Higher routing capacity for complex signal networks

- Integrated ground planes improving EMI shielding

- Weight reduction compared to cable harnesses

- Reliable bending for compact 3D assemblies

Common configurations include 4-layer, 6-layer, and 8-layer designs for advanced electronics such as cameras, wearable devices, and industrial sensors.

Multilayer Flex PCB Manufacturing Process and Capabilities

Professional multilayer flex PCB fabrication requires precise alignment, material control, and process stability. At HILPCB, every stage — from layer buildup to final testing — is executed under ISO and IPC standards.

Key manufacturing capabilities:

- Layer count: 4–16 layers

- Minimum trace/space: 50 μm

- Laser-drilled vias: 0.075–0.15 mm

- Registration accuracy: ±0.025 mm

- Controlled impedance: ±10% tolerance

- Copper thickness: 0.5 oz – 2 oz

- Adhesiveless polyimide for ultra-thin flex sections

Our process includes laser direct imaging (LDI), vacuum lamination, and AOI inspection, ensuring consistency across all multilayer builds. Blind and buried via designs can also integrate with rigid-flex PCB assemblies for maximum design freedom.

Multilayer Flex PCB Design and Material Selection

Designing a multilayer flexible circuit involves balancing performance with manufacturability. Proper stack-up design and material choice are critical to achieving stability during bending, reflow, and operation.

Common material systems:

- Base film: Polyimide (PI) or LCP for high-temperature and RF stability

- Copper foil: Rolled annealed (RA) copper for dynamic flexing; ED copper for static folds

- Adhesive: Epoxy or acrylic bonding films for 3–6 layer builds

- Coverlay: Polyimide with acrylic adhesive, or photo-imageable solder mask for fine-pitch areas

Design guidelines:

- Keep bend radius ≥ 10× total thickness

- Avoid vias in dynamic flex zones

- Use symmetrical stack-ups to prevent curling

- Staggered via placement for reliability

- Embedded ground planes for signal integrity

These design principles minimize delamination, stress cracking, and impedance variation in multilayer constructions.

Multilayer Flex PCB Materials and Trusted Brands

Choosing the right multilayer flex PCB materials determines not only mechanical flexibility but also long-term reliability and thermal endurance. At HILPCB, we use globally recognized substrate and copper foil brands to ensure every flexible circuit meets demanding application standards.

1. Base Films (Substrates)

- Polyimide (PI): The most widely used flex substrate for multilayer constructions. It combines high thermal stability (up to 400°C), low dielectric loss, and excellent mechanical strength.

- Common brands: DuPont Kapton, UBE Upilex, Kaneka Apical, Panasonic Felios

- Liquid Crystal Polymer (LCP): Ideal for high-frequency multilayer flex PCB designs due to its ultra-low dielectric constant (Dk ≈ 3.0) and moisture absorption below 0.02%.

- Polyester (PET): Used in cost-sensitive consumer applications requiring moderate flexibility and temperature range (<120°C).

2. Copper Foil Options

- Rolled Annealed (RA) Copper: Preferred for dynamic flexing and repeated bending applications, providing superior fatigue resistance and ductility.

- Electrodeposited (ED) Copper: Cost-effective choice for static or semi-static multilayer flex circuits where high flexibility is not critical.

3. Adhesive Systems

- Acrylic Adhesives: Excellent bonding and flexibility, widely used in 2–6 layer designs.

- Epoxy Adhesives: Higher glass transition temperature (Tg) and better chemical resistance for automotive or aerospace applications.

- Adhesiveless Lamination: Copper directly bonded to polyimide without adhesive layers, reducing total thickness by 20–30% and improving signal stability for high-speed multilayer circuits.

4. Coverlay and Surface Finishes

- Polyimide Coverlay Films: Provide mechanical protection and insulation for flexible regions.

- Photo-Imageable Coverlays: Enable finer openings for dense multilayer flex circuits and HDI PCB integration.

- Surface Finishes: ENIG or Hard Gold for reliable solder joints and connector pads, ensuring long-term oxidation resistance.

By sourcing all materials from trusted suppliers and maintaining material traceability, HILPCB guarantees consistent performance across multilayer, rigid-flex, and hybrid PCB assemblies.

Applications of Multilayer Flexible Circuits

Multilayer flex PCBs are widely used in space- and weight-sensitive products that demand high performance:

- Aerospace and Defense: navigation, radar, and avionics modules

- Medical Devices: imaging sensors, flexible probes, and implantable systems

- Automotive Electronics: ADAS cameras, infotainment units, and interior lighting

- Industrial Controls: motion sensors and compact robotic modules

- Consumer Electronics: foldable smartphones, wearables, and 3D interconnects

HILPCB supplies multilayer flex circuits that meet IPC-6013, ISO 13485, AS9100, and IATF 16949 standards — ensuring compliance across global markets.

Choosing the Right Multilayer Flex PCB Manufacturer

Selecting a reliable multilayer flex PCB supplier goes beyond just layer count or price. You need a manufacturer that combines engineering expertise, process control, and assembly integration.

Why engineers choose HILPCB:

- 10+ years of flexible and rigid-flex PCB experience

- Full in-house production — design, lamination, plating, and SMT assembly

- Consistent material sourcing for matched CTE and reliability

- Comprehensive testing: AOI, impedance, flex-cycle, and environmental validation

- Fast prototyping and scalable mass production

By manufacturing all PCB types — rigid, flex, rigid-flex, HDI, high-frequency, and aluminum boards — under one system, HILPCB guarantees mechanical and electrical compatibility across your entire electronic assembly.