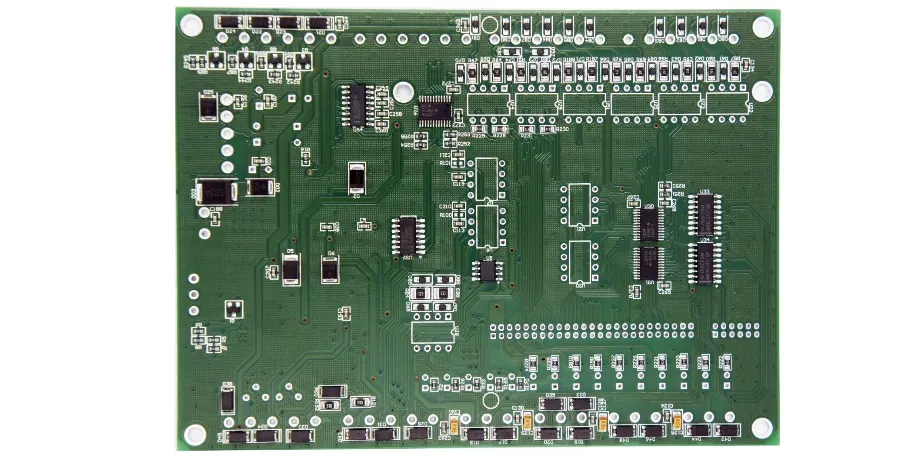

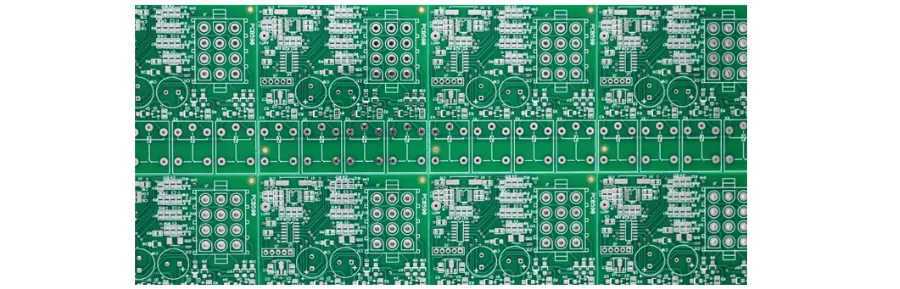

At Highleap PCB Factory (HILPCB), we specialize in providing advanced PCB manufacturing solutions, including OSP (Organic Solderability Preservative) PCBs. OSP is a widely used surface finish known for its eco-friendly properties and cost-effectiveness while maintaining high solderability and reliability. This surface finish offers a smooth and consistent coating that ensures reliable electrical connections in a variety of electronic applications.

What is OSP PCB?

OSP (Organic Solderability Preservative) is an environmentally friendly surface finish that applies a thin organic layer onto the copper pads of a PCB to protect them from oxidation. Unlike other finishes, OSP does not involve the use of metal coatings like gold, palladium, or tin-lead. The organic layer serves as a protective barrier against corrosion and ensures that the copper surface remains solderable throughout the PCB manufacturing process.

The OSP process is simple and cost-effective, involving the immersion of the PCB in an organic solution that forms a thin, non-metallic coating. It provides excellent solderability, particularly when using lead-free soldering processes, and is ideal for a wide range of electronic applications.

Key Features of OSP PCB:

- Eco-friendly: OSP is a lead-free and non-toxic finish, making it an environmentally sustainable choice compared to other metal-based finishes like HASL or ENIG.

- Cost-Effective: OSP is one of the most affordable surface finishes for PCBs, offering a reliable solution without significantly raising production costs.

- Good Solderability: The OSP finish ensures excellent soldering performance, particularly for fine-pitch components, making it suitable for high-density PCBs.

The OSP PCB Process

The process of applying an OSP finish to a PCB involves several key stages, each of which is crucial to ensuring a reliable and high-performance surface finish. Here’s a breakdown of the process:

- Surface Preparation: The copper pads on the PCB are first cleaned to remove any oxidation, grease, or contaminants. This step is critical to ensure proper adhesion of the OSP coating.

- OSP Coating Application: After cleaning, the PCB is immersed in an organic solution that reacts with the copper surface to form a protective layer. This layer is extremely thin—typically between 0.2 to 0.5 microns—but provides a robust barrier against oxidation and corrosion.

- Drying: The PCB is then dried to remove any excess solution and ensure a uniform coating. The organic layer must be stable and intact for the PCB to perform reliably during soldering.

- Inspection: Once the OSP coating is applied, the PCB undergoes a thorough inspection process to check the uniformity and integrity of the organic layer. This step ensures that the finish meets the required standards for solderability and performance.

- Final Soldering: The OSP finish is compatible with both wave soldering and hand soldering processes, ensuring the PCB maintains excellent solderability during assembly.

Advantages of OSP PCB

OSP PCBs offer several advantages that make them a popular choice in modern electronics manufacturing. First, they are environmentally friendly due to their lead-free and non-toxic properties. This makes them compliant with RoHS standards, significantly reducing the environmental impact compared to other surface finishes like HASL or ENIG.

Another major benefit of OSP is its cost-effectiveness. Unlike finishes that require expensive metal layers such as gold or palladium, OSP offers an affordable and reliable option for high-volume production. Its minimal thickness ensures that the electrical properties of the PCB are not compromised, making it an excellent choice for high-density designs where signal integrity and impedance control are critical.

OSP is particularly favored for its excellent solderability, especially in lead-free soldering applications. This surface finish ensures a smooth copper surface, ideal for consistent solder joints. It is widely used in consumer electronics, automotive sensors, and industrial electronics, where performance, sustainability, and cost-efficiency are essential. Products like smartphones, wearables, and control systems often rely on OSP PCBs for their reliability and affordability.

OSP PCB Applications

OSP PCBs are suitable for a wide range of applications across various industries. Some of the most common uses include:

- Consumer Electronics: OSP PCBs are ideal for products like smartphones, tablets, and wearable devices due to their cost-efficiency and reliable performance.

- Automotive Electronics: The eco-friendly and durable nature of OSP makes it a great choice for automotive applications, especially for sensors and control units.

- Industrial Electronics: OSP is also used in industrial electronics, where reliable and affordable surface finishes are needed for mass-produced components.

- Communication Devices: High-frequency PCBs in communication devices benefit from the low-profile finish and excellent solderability provided by OSP.

- Medical Devices: While OSP is less common in high-reliability medical applications, it can still be used for less critical components due to its affordability and excellent solderability.

OSP PCB vs. Other Surface Finishes

Choosing the right PCB surface finish requires balancing cost, performance, reliability, and environmental impact. While OSP (Organic Solderability Preservative) is a popular choice for its simplicity and eco-friendliness, it’s important to evaluate how it compares with other common finishes like HASL and ENIG.

OSP vs. HASL (Hot Air Solder Leveling)

- Solderability: OSP offers excellent solderability with a flat surface, making it ideal for fine-pitch SMT assembly. HASL, especially the leaded version, may result in uneven surfaces and is less suited for fine-pitch components.

- Durability: HASL has a longer shelf life and better robustness in harsh handling environments, while OSP is more sensitive to multiple heat cycles and oxidation.

- Environmental Impact: OSP is lead-free and RoHS-compliant, making it environmentally superior. Traditional HASL uses lead, though lead-free HASL alternatives exist.

- Cost: OSP is generally more cost-effective, especially for high-volume, consumer-grade electronics that do not require extended reliability.

Use OSP when: cost is a primary concern and the assembly process is tightly controlled. Choose HASL when: mechanical robustness or through-hole reliability is a priority.

OSP vs. ENIG (Electroless Nickel Immersion Gold)

- Performance: ENIG offers a flat, oxidation-resistant surface and supports both soldering and wire bonding, making it ideal for high-reliability, high-frequency, or long-life products.

- Shelf Life: ENIG has a significantly longer shelf life and better performance in multiple reflow cycles, whereas OSP may degrade with extended storage or thermal exposure.

- Cost: OSP is much more affordable, making it a good fit for low to mid-end products. ENIG, while high-performing, is substantially more expensive due to its multi-step plating process.

- Environmental Factors: OSP is more eco-friendly and easier to handle in terms of waste management. ENIG involves heavy metals and more complex wastewater treatment.

Use OSP when: budget and environmental impact are key considerations. Choose ENIG when: product reliability, long shelf life, or mixed-assembly (SMT + wire bonding) is required.

Why Choose Highleap PCB Factory for Your OSP PCB Needs?

At Highleap PCB Factory (HILPCB), we specialize in high-quality PCB manufacturing and PCB assembly. Our experience with OSP technology ensures that your PCBs meet the highest standards of performance, reliability, and environmental compliance. Whether you're looking for multilayer PCBs for complex designs or high-speed PCBs for demanding communication systems, we have the expertise to deliver. We also offer additional services like turnkey assembly to support your complete project needs.

For further information on our capabilities, check out our other products such as Multilayer PCBs, High-Speed PCBs, and Rigid-Flex PCBs.

FAQ

What is the key advantage of OSP over other surface finishes? The main advantage of OSP is its cost-effectiveness, combined with excellent solderability and eco-friendly properties. It's ideal for cost-sensitive applications where solder performance and environmental impact are key considerations.

Can OSP be used for high-density PCBs? Yes, OSP is suitable for high-density designs. Its thin coating ensures that the PCB’s electrical properties are preserved, making it an excellent choice for fine-pitch and high-density applications.

How does OSP compare to HASL in terms of durability? While OSP provides excellent solderability, it is not as durable as finishes like ENIG or HASL. OSP is best suited for applications where long-term durability is not as critical.

How do I specify OSP in my PCB design? Simply specify "OSP" or "Organic Solderability Preservative" in the surface finish section of your design files. Make sure to include any specific area requirements if selective finishing is needed.

What are the limitations of OSP? OSP’s main limitation is its moderate durability. For applications requiring high thermal cycling resistance or exposure to harsh environments, other finishes like ENIG may be more appropriate.